Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Cassiopeia"

“Better to have, and not need, than to need, and not have.”

--Franz Kafka

Writer, 1883-1924

Decades ago, one of my early locking sheath users was a United States Navy Seabee. He loved the tactical sheath I made for his knife, but because he was onboard ship, he didn't like the position of the sheath on his belt. He wanted it to ride lower on the belt, with the handle below the belt line, like a lowered holster for a firearm. He devised his own crude idea of this with military MOLLE webbing and duct tape (yes, duct tape) to illustrate the idea for me, and I went to work. This was the birth of the very first belt loop extender.

Note: my earliest belt loop extenders are described on a special archival page on the website at this link.

In the firearms world, a belt loop extender arrangement is called a "drop holster," because it drops the firearm to a lower position. Dropping even lower and it becomes a "leg holster," or a "drop leg holster." The holster itself may lower and position the firearm, or it may have webbing or textiles to do the job. In choosing the name for this device, it was clear to me that it extends the belt loop to a lower position. This is why I use the name "Belt Loop Extender."

No matter what you call it, a drop leg sheath, or a thigh sheath, it's not the actual sheath that lowers the knife to a location below the belt loop; it's a specialized piece of gear made of webbing, high strength reinforcement, acetyl thermoplastic, and metal. Since I use a universal locking sheath or hybrid-tension locking sheath, or tab-lock sheath, I design and offer the accessory to lower the position of the knife. This is my belt loop extender, or BLX.

A simple belt loop extender only does that, lowers the sheath position. Right away, I realized that simple belt loop extenders weren't enough, that the extender could offer other features, such as a place to nest a diamond pad sharpener and a web pocket for the LIMA flashlight. This was the beginning of my "Ultimate Belt Loop Extender," which comprises most of the extenders I make and is tagged: UBLX.

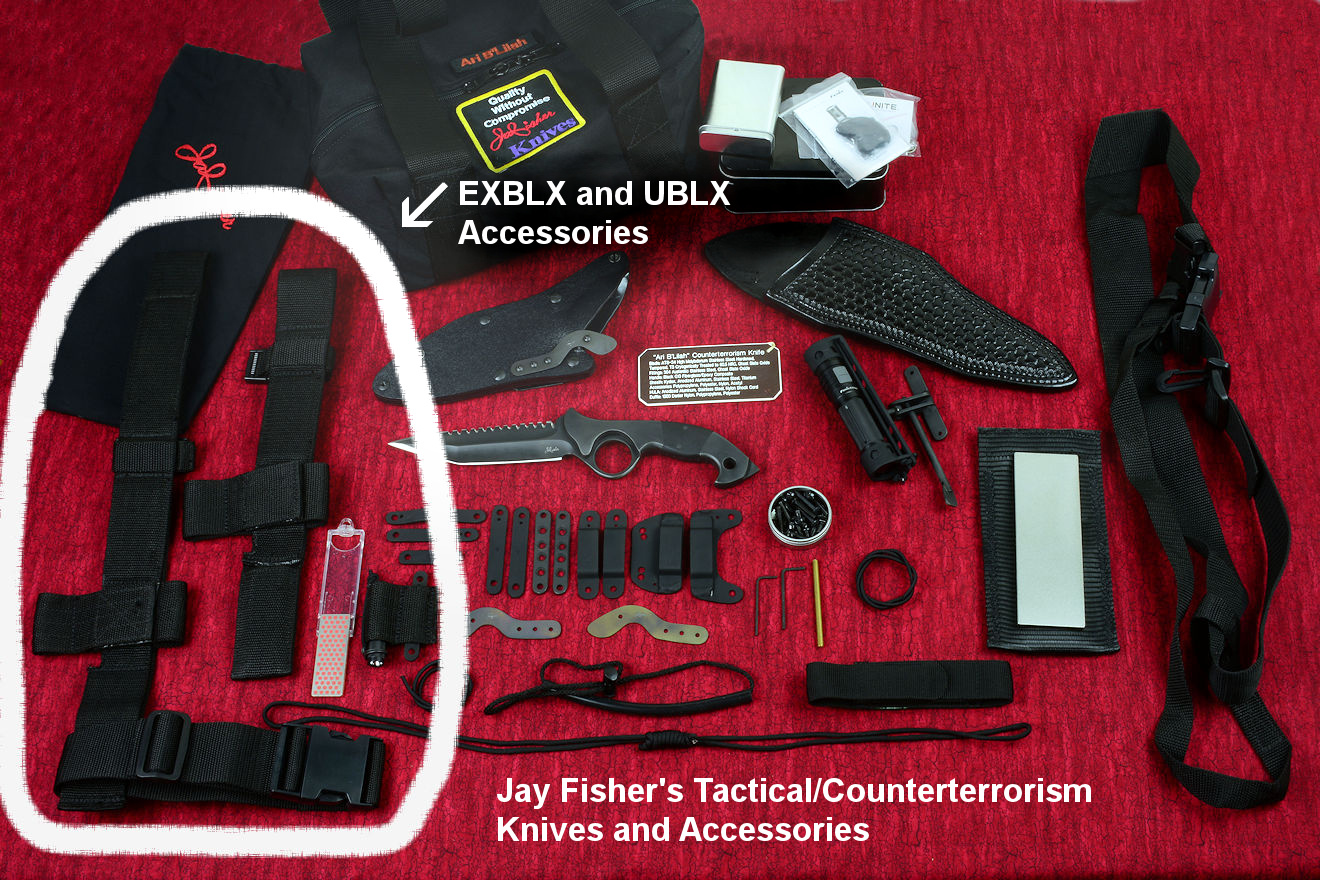

I also offer even longer, lower extenders. These are not just for very large knives; I've learned from US Marines that a lower position on the thigh is often the most convenient place to wear even smaller fixed blade knives. So I offer EXBLX, the Extra length Belt Loop Extenders which have anchor straps around the thigh, just above the knee.

A new addition to this idea is my Modular Sheath Frame System (MSFS), which has a modular, changeable sheath frame and is quickly adapted to a variety of wear options, the UBLX being just one of them. I'll cover that on a different page of the site.

This page is all about the UBLX, and the EXBLX, accessories that lower my knife sheaths to a "below the belt" position.

I hand-make all of the physical working, mounting, hardware, and wearing components of my accessories in my shop-studio. I farm nothing out. Like all of my custom tactical knife gear, the entire belt loop extender is custom-made to fit each individual knife. Some of my accessory gear (sharpeners, flashlights, magnesium firestarters) are separate components and have somewhat universal fittings on all my knife sheaths. However, like the sheaths, the UBLXs won't fit other knives; the UBLXs are custom-made to fit one individual knife and sheath combination.

One of the main reasons for this is that because each knife is different, so is the size and shape of the sheath. This means that the bolt pattern, distance to the top of the knife butt (when sheathed) and widths are all different. So each UBLX must be made to match-fit a single knife/sheath combination.

I make the UBLX web frames in nylon or polypropylene, and stitch them with very heavy polyester thread with professional machine stitching. I have five dedicated machines to do these jobs. The hook and loop (Velcro®) retainer pads are adhesive and cross-stitched. There is a "drop" area, where the actual extension of the web between the loop for the belt and the top of the sheath is located. In older/earlier models, I heavily zigzag-stitched this area to stiffen it. In the newer models, I insert a piece of acrylic stiffener to stop this area from collapsing or folding as the knife is pulled up and out of the sheath. The acrylic stiffeners are lightweight, waterproof, and permanently mounted within the webbing. All metal parts, if applicable, are stainless steel, and all plastic buckles and hardware, if applicable, are acetyl .

Acetal plastic, also called polyacetal and polyoxymethylene (POM), with the tradename Delrin, is a general purpose, semi-crystalline, engineered thermoplastic. Acetal is commonly used for parts that need to be very stiff, have low surface friction and good dimensional stability. Dimensional stability is the ability of a plastic part to maintain its original dimensions when it is exposed to changes in temperature and humidity. This plastic is so durable, it's used to make plastic machine gears, and it's food and safety compliant.

Describing the UBLX may seem a bit complicated, but I assure you that the device is extremely simple and intuitive when you have it in your hand. I've made many dozens of these for decades, and never had a complaint about a single one.

The UBLXs have a T-strap design of two main parts (see the annotated photos below):

The UBLX is an extender for the belt loop position, effectively lowering the knife with the handle at or below the belt line. The main reason for this is that when the die-formed aluminum belt loops are used, they can locate the knife in an uncomfortably high position, depending on the use, wearer, preferences, or mission. Also, some clients find reaching high up under their ribcage to unsheathe the knife difficult. Sometimes, sitting, crouching, or movement is inhibited when the knife rides high on the belt. Because this can sometimes be a problem, and knifemaking is about solving my client's problems, I've created and refined the UBLX over the years.

The UBLX mounts to the knife sheath. It's not carried; it doesn't hold, embrace, or coddle the knife and sheath with rope, cord, weak eyelets or any of the inferior contrivances used by most other knifemakers and all manufacturers. The sheath is firmly and solidly mounted to the UBLX with stainless steel machine screws. In rigidly mounting, the sheath is fixed to the web frame of the UBLX. The belt is threaded through the belt loop opening, and the sheath and knife are located to a lower position. By the way, the belt loop is fully enclosed and does not depend on stitching at the loop wear points. To wear out the belt loop means wearing through two layers of heavy duty polypropylene or mil-spec nylon webbing. The location and length of the accessory places the knife handle at or below the belt line. Longer EXBLXs and leg straps are detailed later on this page.

Because the sheath alone is mounted to the UBLX, the knife handle can move about and this can cause problems with the handle "flopping" around and away from the body. This is why all of my BLXs have anti-flop shock straps. These are wide elastic, ocky, or bungee, or in newer models, 1" wide webbing straps with acetyl buckles to prevent the knife handle from moving away from the body, keeping the assembly tight, close, and compact. When the knife is to be removed (unsheathed), the strap is either unsnapped, or unbuckled with a pinch of the fingertips, allowing the knife to be unlocked and removed from the sheath.

Some of the anti-flop shock straps are mounted at an angle, depending on the knife design (think tactical push/punch daggers or angled recurve-bladed knives).

The UBLX usually has a pocket for the LIMA accessory flashlight, and it's built right in, so the client does not have to wear the LIMA web frame and mounting strap if he's wearing the UBLX. Most of the UBLXs also have the sharpener pocket built in. To remove the sharpener, the sheath must be off the body, and the hook and loop pads opened; the sharpener cannot fall out or come out without the hook and loop opened.

To mount the UBLX to the sheath using included hardware and fasteners, please look over the instructional photos below. They are pretty simple.

Slow and easy! The only thing to be very careful of is cross-threading the machine screws during assembly and change-out. All of the tactical knife sheaths I make have all stainless steel fasteners, and if they are started crooked and forced, they will lock up and be ruined. The simple rule is to start every screw by finger pressure first, before using a tool to tighten. Because they are stainless steel, they will never rust, corrode, or seize from exposure even in marine (salt water) environments.

In tightening, these accessories don't need to be super-tight like the head bolts on an engine. They aren't going to loosen and fall out; and just a bit tighter than finger pressure is all that is needed to secure them. I always include a large variety and length of fasteners for each kit; there will be one long enough to do the job. If it bottoms out in the long female Chicago screw, just use a bit shorter machine screw.

When a United States Marine asks for a feature on a tactical combat knife, I listen carefully. The Marine carries a tremendous amount of gear, and these guys are strong, tough, and incredible warriors. However, the Corps has left them little room for a knife, and this requires some thinking for viable, worthwhile wearing options. This is why I now regularly make and provide the EXBLX in my kits.

This is the same idea as the belt loop extender, but it locates the knife even lower, to a low thigh position on the outside of the leg of the leading hand. I've made similar mounts before, but usually only for very long knives that have sheaths that are so long that they extend down the leg. With the EXBLX, even small knives are worn lower, at the side of the leg, just above the knee. The are secured like any of my tactical combat knives, with a positively locking or hybrid-tension-locking sheath, with the addition on the EXBLX of a wide leg strap.

Since the EXBLX is based on the design of thigh sheath mounts with leg straps, let's look over those to see what the issues are and how I've addressed them. The long sheath mount is very similar to the EXBLX.

For very long knife blades and a low-wearing location for shorter knives, I offer a reasonable, practical, and worthwhile solution for realistic wear. The problem with most of the long knife sheaths for this type of knife is that when the sheath is long, the bottom (tip) of the sheath can flop around. The same problem exists with mounting small knives lower on the thigh. The solution to this is to anchor the sheath to the thigh, just above the knee.

Other knifemakers and suppliers of this type of sheath are woefully inadequate, using lace, cord, or other straps to accomplish this critical job. That is simply not good enough, and here are the reasons why:

How would the best leg and thigh strap work on a long-bladed or low-mounted knife sheath?

To learn more, please look at the group of thumbnail photos of my thigh belt and wear demonstration below.

From the development of the thigh strap, it wasn't hard to realize that to lower a smaller knife to a comfortable area on the leg, simply lengthening my UBLX was the answer. It's mounted just like the UBLX, and has the same pocket for the LIMA flashlight accessory. Once the 2" wide and comfortable leg strap is adjusted and set, it can buckle on and off easily and be fixed at the same size. No tying and untying. No narrow, dangerous, and painful lines, cord, or thongs.

The EXBLX fits anyone with an inseam from 32" on up. For special sizes and lengths I'm happy to build these, since they are custom to the knife.

As described above, these accessories are made of polypropylene, polyester, or Mil-spec nylon and are extremely durable. They can be washed with plain water, or soap water for stubborn dirt, or even hosed off with a garden hose. Remove them from the sheath first, let them hang and air dry.

The fasteners, hardware, machine screws, and straps require little care: wash off stubborn dirt or debris, check to make sure the threads are not damaged. They are all stainless steel, even the blackened and coyote models, so there is little concern whatever!

Wow: how simple is that?

Just like my knives, my sheaths and accessories continually evolve. This is how it should be. I look forward to making any improvements my clients desire, and their input is always welcome. I can't know the range of exposure and missions that they will have in the future, but I'm committed to work with them to make the finest knives, sheaths and accessories possible.

It's an honor to know they will be depended on.

| Main | Purchase | Tactical | Specific Types | Technical | More |

| Home Page | Where's My Knife, Jay? | Current Tactical Knives for Sale | The Awe of the Blade | Knife Patterns | My Photography |

| Website Overview | Current Knives for Sale | Tactical, Combat Knife Portal | Museum Pieces | Knife Pattern Alphabetic List | Photographic Services |

| My Mission | Current Tactical Knives for Sale | All Tactical, Combat Knives | Investment, Collector's Knives | Copyright and Knives | Photographic Images |

| The Finest Knives and You | Current Chef's Knives for Sale | Counterterrorism Knives | Daggers | Knife Anatomy | |

| Featured Knives: Page One | Pre-Order Knives in Progress | Professional, Military Commemoratives | Swords | Custom Knives | |

| Featured Knives: Page Two | USAF Pararescue Knives | Folding Knives | Modern Knifemaking Technology | My Writing | |

| Featured Knives: Page Three | My Knife Prices | USAF Pararescue "PJ- Light" | Chef's Knives | Factory vs. Handmade Knives | First Novel |

| Featured Knives: Older/Early | How To Order | Khukris: Combat, Survival, Art | Food Safety, Kitchen, Chef's Knives | Six Distinctions of Fine Knives | Second Novel |

| Email Jay Fisher | Purchase Finished Knives | Serrations | Hunting Knives | Knife Styles | Knife Book |

| Contact, Locate Jay Fisher | Order Custom Knives | Grip Styles, Hand Sizing | Working Knives | Jay's Internet Stats | |

| FAQs | Knife Sales Policy | Concealed Carry and Knives | Khukris | The 3000th Term | Videos |

| Current, Recent Works, Events | Bank Transfers | Military Knife Care | Skeletonized Knives | Best Knife Information and Learning About Knives | |

| Client's News and Info | Custom Knife Design Fee | The Best Combat Locking Sheath | Serrations | Cities of the Knife | Links |

| Who Is Jay Fisher? | Delivery Times | Knife Sheaths | Knife Maker's Marks | ||

| Testimonials, Letters and Emails | My Shipping Method | Knife Stands and Cases | How to Care for Custom Knives | Site Table of Contents | |

| Top 22 Reasons to Buy | Business of Knifemaking | Tactical Knife Sheath Accessories | Handles, Bolsters, Guards | Knife Making Instruction | |

| My Knifemaking History | Professional Knife Consultant | Loops, Plates, Straps | Knife Handles: Gemstone | Larger Monitors and Knife Photos | |

| What I Do And Don't Do | Belt Loop Extenders-UBLX, EXBLX | Gemstone Alphabetic List | New Materials | ||

| CD ROM Archive | Independent Lamp Accessory-LIMA | Knife Handles: Woods | Knife Shop/Studio, Page 1 | ||

| Publications, Publicity | Universal Main Lamp Holder-HULA | Knife Handles: Horn, Bone, Ivory | Knife Shop/Studio, Page 2 | ||

| My Curriculum Vitae | Sternum Harness | Knife Handles: Manmade Materials | |||

| Funny Letters and Emails, Pg. 1 | Blades and Steels | Sharpeners, Lanyards | Knife Embellishment | ||

| Funny Letters and Emails, Pg. 2 | Blades | Bags, Cases, Duffles, Gear | |||

| Funny Letters and Emails, Pg. 3 | Knife Blade Testing | Modular Sheath Systems | |||

| Funny Letters and Emails, Pg. 4 | 440C: A Love/Hate Affair | PSD Principle Security Detail Sheaths | |||

| Funny Letters and Emails, Pg. 5 | ATS-34: Chrome/Moly Tough | ||||

| Funny Letters and Emails, Pg. 6 | D2: Wear Resistance King | ||||

| Funny Letters and Emails, Pg. 7 | O1: Oil Hardened Blued Beauty | ||||

| The Curious Case of the "Sandia" |

Elasticity, Stiffness, Stress, and Strain in Knife Blades |

||||

| The Sword, the Veil, the Legend |

Heat Treating and Cryogenic Processing of Knife Blade Steels |