Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Cassiopeia"

jay i am looking for a custom sword to spark fire in my eyes every time I look at it.

Suzanne E.

--actual complete email received, 2007

Having a large and active web site since 1996 has, thankfully, brought me a lot of interest, business, partnership with patrons, and knife orders and purchases. Truly, I would not be able to do what I do without the support and contact of new and existing knife clients and people who are interested in fine custom and handmade knives. I am honored, humbled, and grateful to those people who contact me, start a conversation about their knife, and may ultimately become regular clients. That is what this web site is about, pure and simple: my knives, my clients, and my career.

As the web site traffic has grown, people have sent emails about everything related to knives in any way. I suppose that's because they see a large and meaty web site, so the answer or project they seek will be there, and all that has to happen is an email, so they send. During that time, the site has grown, developed, been refined, has had some areas restricted, and evolved. A great deal of that evolution has had to happen to limit the huge onslaught of incoming emails and inquiries.

They sent so many emails that were not related to this site (which is about my knives, knife clients, and career), I became overwhelmed, spending 4 or more hours a day answering their inquiries. I realized that this was time I was taking away from my clients who had ordered custom knives and clients who were watching the site waiting for new inventory knives to come up for sale. In order to limit the flood of email, I created the "What I do and don't do" page.

The "What I do and don't do" page was a hit. It made clear that I would not answer emails unless they were about ordering or purchasing a knife from me. I added some dry humor to it. I added topics as new emails were sent asking for more services. I added links to sites that would help those in need. Although the page reduced the amount of incoming emails tremendously, they still came in because people either ignored the page or didn't believe it applied to them. You can't miss the page; before you email me I specifically link it on the singular email link page on this site. Nowadays, if email still comes in that does not pertain to the knives or my clients, I simply ignore it. Some of it is priceless, so I've chosen to share it here. Don't forget to look at the other funny pages linked at the top of this page.

Please keep your sense of humor when reading through this page. If you don't have a sense of humor, or don't understand satirical, hyperbolic, anecdotal, ironic, juvenile, mordant, or farcical humor, please feel free to browse to another site. Don't feel compelled to email me and tell me how awful I am for having a site that is just about my knives, my clients, and my career. If you do write to complain, I might post your comment here, and others can enjoy it, too!

For all of you who have written to thank me for posting this page and who have enjoyed the emails, letters, and comments, thank you. You are who I've built this for!

Please enjoy, and thanks for being here!

Here's a typical email that I received from an overseas company: I'll asterisk out the important information, so they don't sue me! There was so much bad formatting, extra spaces, font sizes and colors, and confusing formatting that it took quite a while to get this to a readable document!

B*****A TRADING CORPORATION

PHONE: - +9*-05*2-3****98, MUJAHID ROAD P.O.BOX-***, Fax No: -+9*-0*2-4****40

Established-1950, 5***0-SIALKOT,

Distributors, swords, knives, cuttlery

PL visit our website http://a*******.en.ec21.com/company_info.html

1, we being the iso-9002, certified manufacturers & exporters of

all kinds of swords, knives, cuttlery & ancient weapons.

2, all our prices are round about fob us$.5-10 euro, freight not included.,

3, air freight on each sword will be approximatly from 3-5 euro.

4, our minimum order quantity for new custofmer is 10-25-pcs of each quality

5, trial order of diffierent shapes, sizes & qualaties, will take 20-30 days, from the date of receipt of

7, our skilled workers have the capabiliyt to make any of your

special items at worlds best prices exclusivly for you , if you send

its photo, description or sample, which will be returned to you with

2-counter samples for your evaluation, however if we have to make

some special dyes/moulds then price will be little bit high,

SPECIFICATIONS

8, we have two types of quality each has different material composition, & prices,

9, 1st quality is made of importerd japani stainless steel, J-2,

(NEVER RUSTED), temper goes upto 420 rock well hard.temper, using

cold technology, while 2nd quality is made of local stainless

steel, & temper is 200,

10,1st qty swords covers are made of new aluminuim with mettalic

colours, while 2nd qty is made of recycled aluminium,

11,1st qty metal or die casted parts of swords are made of new

pewter, dully plated of 24-karat gold, having 2-3-years guarantee

period, while in 2nd quality all parts are made of re-cycled pewter,

& brass plated, having 3-months guarantee,

12, 1st qty swords stands are made with genuine shisham/diyar wood,

dully hand engraved, & lakh polished, while in 2nd qty stands are

mae of artificial wood, plain winboard, the same applies to knives

covers, 1st in real leather, 2nd in artificial leather.

hoping to receive your positive responce untill then by

abid mughal

What happened to number 6? Must be unlucky. Just what does Abid mean by "a little bit high?" Japani steel? 420 Rockwell? (knives are typically 56-60 Rockwell) Cold technology? What is J2? 200 temper? Metallic colors of aluminum covers? Pewter? Dully plated? Shisham wood? Lakh polished? Does that mean lacquer? Artificial wood? Winboard? Artificial leather?

Abid is still waiting for my response.

Hello Jay,

I was just wondering if you can smelt a steel alloy for use in a custom sword? I still need to do more research

about what style of sword I want, but I know I want it to be insanly strong.

Later, K.

My response:

Hello, K., thanks for writing.

Though I don’t usually answer “how to” letters, I just wanted you

to know that the best steels are made professionally, in vacuum

furnaces where the steel alloy elements are closely controlled for

maximum purity. There are some guys that are smelting their own ore,

making what our industry calls “primitive” blades by old methods,

and there is a following for those types of work. But it is a far

cry from metals that are made for professional use as cutting tools

for industry, machine shops, or the

military industrial complex. Fortunately, these steels are available

for use in custom knives and swords, if the client desires to pay

for such quality.

When you use the term “insanely strong,” I think I

understand what you’re interested in. The reality is that “strong”

is not a word that is clearly and usefully used in describing steel

properties, as there are many more considerations such as toughness,

hardness, wear resistance, and machining workability. Other terms

used are corrosion resistance, surface treatments, specific

applications and cost. There is a lot of hype on the internet about

what constitutes the “right” blade steel, and all I can tell you is

that it depends on many factors that must be considered. There is no

super steel, just good, reasonable choices. Please read my

FAQ page here and my

Blades page here for more

information.

Thanks, Jay Fisher

I will be in South Africa and Nimibia next year if I have time I

would love to see your knives. In the meantime a brochure would be

nice.

M. E., New Albany, IN.

PS. directions would be great.

My response:

Hello, M. Thanks for writing. From your text, I'm wondering if you had intended to send this email to me,

not some other maker. That is because I live in Clovis, New Mexico, USA, not in Africa. ???

If you are still interested in knives, please let me know.

Thanks,

Jay Fisher

I love this! Directions would be great inside Namibia (from Indiana!) Is NM short for Namibia? Or maybe there's a new state named Namibia-- and no one told me!

This is R. from WV, I am

looking for a professional sword maker, and I readed your

profile on the site, and I think you can make a sword for

me. I don't care how much money take to make it, but I just

needed to made the sword. The sword is original designed by

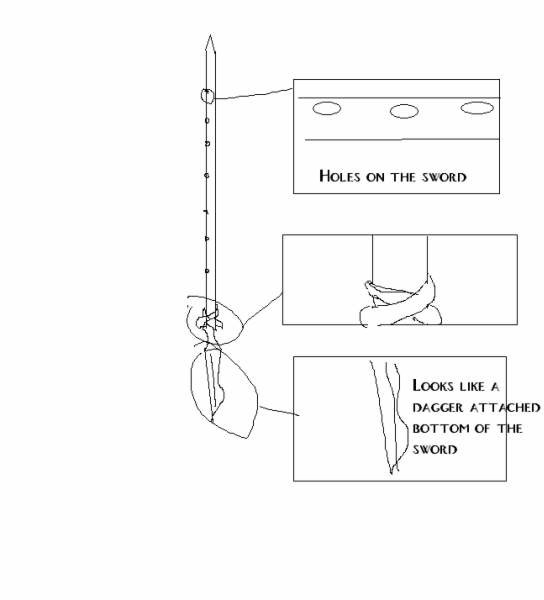

me, and I also send you a drawing of it. I know its not

really detail but hopefully you get what I mean. And if you

want more information on how the sword are supposed to look

like, send me an e-mail, and I will be right with you.

PS this is just an e-mail to

ask you if you're interesting to making a sword for me or not.

Above: This is the actual drawing the client sent to me for consideration (I'm not kidding!)

Jay,

heres a little bit of the detail of the sword: Sword Legnth: 32"Dagger: 17.5" Sword are single-edged

Dagger are double-edged Handle Materia: leather Scabbard: (I will send you a picture of it) Please send me your mailing address, because I want to send you a few

very detail sword script pictures. And it includes the drawing of the sword, dagger, scabbard, and the whole thing.

And plesae note that the picture I sent you yesterday its just an idea, and please don't start to making the sword

until I send you the pictures, and of course, don't forget to tell me how much its gonna cost and I'll send

you the first deposit(or one payement) whenever you start the sword.

Thanks~ R.

Okay so the guy's not an artist. That's okay, I'm still trying...

Dear R.,

Wow. The dagger is a short sword in itself! You can send information to:

Jay Fisher

1405 Edwards

Clovis, NM 88101.

Please send copies, not originals. Once we figure out the details, I'll quote you a price,

then you can decide if that is acceptable. If you do accept,

I'll require half down before I start the project.

Thank you,

Jay

Jay,

do you think you can give me more ideas about the swords? hey,

why don't change sword legnth to 40"? and dagger...? I don't know

how regular dagger length should be... you know what kind of sword

I'm want right, sword with dagger attached to it...!

Stupid me, I should know what kind of sword he wants!

R.,

It is unusual to see a dagger as part of a sword handle. The

reason is that when the sword is held, the dagger blade will be

pointed toward you, not your opponent. But as an artistic piece,

it is occasionally done, and can be quite beautiful.

As far as dagger length, that depends on the design. A very long

dagger blade will mean that the sword would be held farther away

from the body, and may not even be possible.

So you have an idea of the kind of work you will be

investing in, I want you to know that my sword prices start at

$2400, and are typically $3000-6000,

some much higher. I make only real swords, and they require a

lot of work and time. Each piece is quoted individually, and is

one of a kind. If you wish, send me

copies of your drawings and we can discuss details.

Thank you,

Jay

Evidently, I was out of his price range; I never heard from him again. Sigh... I was looking forward to seeing that baby in the drawing.

Here's a typical scam letter. These guys are overseas, and have in their possession some stolen credit card numbers (identity theft) and want me to send them knives. When I do, I'll later find out the cc number is invalid, and my knives are gone... it's happened to a lot of makers. I included the fake name, too, as I'm certain this is a scam. I get a couple of these a month.

I Mr phillips will like to know if you have recieved a mailsent from me to you dated 03/05/05.I do have a

problem with my computer so i need to re-sent this mail as written below to you.I so much apologise

for the inconviniences i might hve cuased you.

Mail dated 03/05/05 is given below:

Hello Sales,

I have an order supply for the purchase of handmade Knife which will be delivered to a client of mine.your

email was forwarded to me by some admires of your good job.I will want you to give me the list of the handmade

knife you have in stock with their unit prices so as to forward the needed quantities to you.to

prepare a preforma invoice for the order. I awaits your urgent response as soon as

possible. Thanks.

Regards,

MR. PHILLIPS MORINHO.

My response:

Dear Mr. Morinho,

Current available knives and prices are posted here:

Current Knives for

Sale. I accept money orders or cashiers checks with first time customers.

Thank you for your inquiry.

Jay Fisher

Of course, I never hear from them again, as they're only interested in credit card scams

Hi,

I will want to order from you, so i will want to inquire about you humble services

a: Do you accept credit card

b: Do you ship to

Nigeria

so get back to me as soon as possible so that we can proceed.

Yours Faithfully.

Tunde Micheal

This is a typical Nigerian internet scam. By the way, the email address was from Italy. Despite his poor attempt at humility (whose humble services? I'm not humble!), there are some blatant things missing from his email. First he doesn't care what knife he gets, just any knife shipped will do. Sometimes, these letters request dozens of knives. And he's tipped his hand by asking for a credit card purchase. This means he has committed identity theft, and obtained enough information about an individual to either obtain a credit card in his name, or has the cc info already. What he wants me to do is take the bait, accept his credit card (which will initially go through as a purchase, then weeks later be denied), and send him knives. By the time I find out the cc is invalid, he's long gone with my knives. There are lots of makers who've been taken by this scam. I used to answer these letters telling them that I only accept direct wire transfers, or admonish them for their sins, hoping to embarrass them into a relenting, but I realize this is useless, so I just delete the email.

At the head of this email was a "signature" graphic included: a face with some background and some post modern text, all in rather ugly shade of brown. Probably something created in a community college graphics design class.

Jay,

I was just wondering what it would cost for a dagger and a stand for it that

was completely custom? I don't know much about daggers, but am looking at

getting one for symbolic purposes. If I presented an artisit design, could you

do it? Is your skill level able to pull off something from paper?

Thanks in advance,

Great website and very informative. I would consider a resign though

for display. The average person wouldn't have strained so much to

find what they are looking for on the site. The content is good.

--S.C.

My response:

Hello, S. Thanks for writing.

The price of an art dagger completely depends on the components

of the dagger. Also, the finish must be considered, and

embellishment, tooling, stand, case, or sheath. There are a lot

of options when one chooses a complete custom knife. I can and do work

with clients’ designs, but because this entails a lot of

drawing, tuning, consideration for geometry, steel types, and

general design work, it still requires the design deposit. You

can

read about the details of the design fee here.

Thank you for your comments about my site. The site is complex; it’s a very complex field of artistry that I’m in. I’m not worried about the “average person” finding their way through my site, my site is geared toward knife aficionados and professionals, and they are very happy with the content and layout. Ah, if this field were only simple enough to have a simple site, with a couple pictures, and about three prices for knives… (smile).

May I be so bold as to offer you some advice, in kind? When you

include your graphic with your email, nearly every firewall and

modern email program stops your email cold, because of the

possibility of the graphic containing malicious code. I had to

retrieve your email from beyond my firewall. I almost deleted

it… just a head’s up.

Thanks for your interest, and I’d love to see your design.

--Jay Fisher

I must have upset them, because I never heard from them again! Oh, well...

Here's one that came from a forum posting: a response to a knife picture and description I posted. There's more here than initially meets the eye.

i don't know man, you've got some nice knives on your site, you may be a very good knifemaker, sorry that i'm saying it, but none of your knives really amazed me, and i felt really confused bout your topic what I don't do..that article on your site sounds really arogant, I'm sorry, it's probably only my opinion...

This flamer had then erased his email after

he'd thought about it. But it was too late, his posting went right

into my inbox, because I had subscribed to my own post. So I looked

him up and sent an email directly to him asking if he had authored

the post. He was emailing from the Czeck Republic.

His reply:

yes, it was, but after a few minutes, i deleted it and was going

to write you via e-mail, there's no need to take my personal opinion

to public, it was my (very) honest opinion, i'm sorry if you feel

insulted, but the part i was talking about really made me little

confused, you know.

O.B.

I answered.

Mr. B.,

Thank you for answering my query. I understand that my style of

knives are not appealing to everyone, just as your knives are

certainly not. As a professional, I will refrain from evaluating

your work with my own very honest opinion, after having seen it.

His knives were not just a beginner's work, they were poor beginner's work on kit knives.

There should be no confusion about the part of my website called "What I do and don’t do." I tried to put in clear and sometimes humorous terms what it is I do, to help those who are looking for services I do not offer.

I simply did a user name search and found out that he had wanted someone to help him make multi-bladed folders, and he evidently took exception to my clear refusal to offer a service he wanted.

You are entitled to your personal opinion, just as I am. The opinions posted on my website are my own, based on my own 27 years of knife making and thousands of knives. If someone does not agree with my views, and does not find answers there, then he may look for opinions elsewhere.

He felt the need to slam my work, because of his own frustration by not being able to find anyone to help him.

I also do not post pictures and information on knife forums for the approval and evaluation of other knifemakers, or those who try to be. I post because friends and clients are genuinely interested in what I am doing, and they have asked me to post.

Yeah, like I was waiting on his opinion and approval after 2000 sold knives.

In doing so, I do not court or invite flaming emails, and I do

not send these types of comments to others, and I appreciate that

same respect from others.

Thank you,

Jay Fisher

He felt the need to respond further.

ok, I'm sorry to make you feel insulted, that's never going to

happen again Have a nice day

O. B.

Mr. B. does not have the power to make me feel anything, though he thinks he does. He was, however, insulting, for no other reason than I don't offer a service that he wanted. He claims in his profile that he is a law student, and unfortunately, he will be an ultimate failure at any endeavor he tries, because he doesn't understand that insulting someone will not help you get what you want. The world is full of these people. They go through life in misery, trying to bring others down to their level, in order to feel better about themselves. I'm sure, dear reader, that you can list several that you know and have to deal with...

Here's another one from a fine foreign manufacturer. I sometimes wonder what American companies they are making knives for.

Dear Sirs,

We, J***I DEVELOPMENT CO., LTD., specialize in knives, like

hunting knives, pocket knives or decorate knives even Parts for gun.

Which gun?

We use fine blanking way to fabricate knives.Ah, yes, grasshopper, the rare and mysterious "blanking way." I've heard of it, but I thought it was only a myth-

That is why our quality is the best.

no doubt, with all that blanking going on

We do not have low end knives except quality ones. Like some famous brands are our customers. Except knives, we also can offer any parts for knives.

What famous brands? Some major knife manufacturers?

Also, you can visit our website www.j******h.com and you will know more about us.

Okay, the website does not exist. But have no fear, your favorite knifemaker has located the company and discovered that they do indeed make knife blades, parts, and components for US factories! This junk might just be in that factory knife you bought! They're located, of course, in Taiwan, Republic of China. How about that? And they do talk about the mysterious blanking way. What it appears is that they use saws to cut out material rather than a plasma cutter.

If you have any question about knives, just advise us. Also, your custom design is welcome. Have a nice day !!!!

And I did!

This came in via an email. Though this guy had to read my specific request to read "What I do and don't do" on my site before emailing, he was sure he was special and I would make the handles he wants for his knives, which I specifically do NOT do.

Jay,

I like your work. I found your site while doing a google search

for orbicular jasper. I read a lot of your material about gemstone knife

material. I have been a rock hound for decades, a mineral dealer for a few

years and for a short while, a seller of meteorite Damascus. Shortly, I will

come into possession of two or three full tang, ground meteorite Damascus

knife blanks. I have also acquired some very nice chrysoprase, Morgan Hill

Poppy Jasper (orbicular) and Big Sur Jade that I would like to fashion into

knife handles for this Damascus. Unfortunately I do not have the equipment

or skills to accomplish this task. I would like to send you the knife blanks

and precut lengths of gemstones for you to fashion into knives. You would

have to add bolsters and grind and polish the handles. All you need to tell

me are the dimensions of the gem blanks you need for the handle material. I

do have a highland park to cut the gem material with. If you can help me

with this, I will display the knives at the Blade show in Atlanta this June

giving you full credit for the handles. Some idea pf pricing will be nice

also.

Thanks, V.P.

I emailed him back my list of what I do and don't do. It's a very clear professional list; it starts with an apology from me for not being able to do what he wants. I highlight the exact part of the list (that he ignored) so it would be clear to him that I cannot perform the service (putting handles on his blades) that he wants. He then responded:

thanks for the reply. I failed to read what you don't do before I sent the email. Yes, I have found most knife makers to have egos that will not allow them to work on other peoples stuff. Thanks anyway and have a nice day

I could not let the abrasive tone of his comment stand. Who do these guys think they are, that because I won't work for him on his pet project it's because of my big ego? What, I don't have the right to say no? I replied:

Hello, V.

I don’t ordinarily respond to letters such as yours, but I

feel you deserved a more detailed explanation, as obviously

you’re a bit miffed about it. It is not an EGO that prohibits me

from working on other people’s stuff, it’s mainly the fact that

it would devalue all my previous and future work for my clients.

You see, they have invested in my work because it is exclusive,

and they intend for the value of the pieces to appreciate over

the years, which will happen if I don’t farm out other work to

or from projects other than my own. Once a maker starts doing

this, the investment value of his pieces drops. It’s really that

simple. That’s not fair to previous clients, and I do have a

duty to them, as they have invested a great deal of actual money

and trust in what I do.

I’m sorry that you have not found a maker to work on your

pieces, but I’m confident that you will find one if you just

keep looking. Good luck and I wish you all the best.

Jay Fisher

He had to have the last word:

Jay,

life is too short to be miffed.

And yet somehow he was...

And another nice company from India. They are very careful on their website to state that they do not use child labor. It's interesting that their clients in the west are promoting that attitude, and hopefully, that practice

Dear Sir,

we are doing dealing with the email for many times.But we are sorry that

we have not got any response from to you. And we dont know what are the causes for the same.

He is upset that he doesn't know why I don't answer. By the way, this is the first email I've ever received from these guys.

But I want to say to you if you given us chance to serve in your organisation. we

will do our work with best satisfaction. If you have any requirement for any

order. Then given an opportunity for the bone and horn or sample

anything else.

Thanks with regards

Prop

R.Malik

Is that an abbreviation for proprietor? I rarely use any kind of bone, so I'm afraid I wont' be doing business with Mr. Malik. Years ago, I got a request from a guy to use a human bone on a knife handle. No kidding! He didn't say whose bone it was, and I didn't ask, and our conversation was very short. Makes you wonder, doesn't it? And NO, I didn't take him up on his idea.

Here's another nice company from Pakistan. This letter was titled "Damascus Kitchen Knife" to lure me into thinking it was an actual inquiry to order a custom knife. Clever, weren't they? They figured that once I opened their email, I would be hooked, and have to use their services. I originally tried to include the letter in the original font styles, but they were so mixed and varied and rare that it crashed my web site developing program! I had to convert the typeface to a standard font, so the email looses some of its .... glamour.

Dear Sir,

We have pleasure to introducing you ourselves as Manufacturers & Exporters of

all sorts of Damascus Knives & Hunting knives, Swords, Cutlery Kitchen knives &

Axes, Full Wooden Sword, Leather and Stainless Steel Helmet, Scissors & more new designs of all above

One wooden sword and a leather and stainless steel helmet?

Items which are specialized of the best selected durable materials under the skilled workmanship and an expert

supervision in our own FACTORY. We guarantee for our quality as every Pieces thoroughly checked at every stage.

Our product are fine in quality and the prices are most attractive. We

sincerely hope that we could establish business relations with you.

Please visit our website:-

URL removed. I'm jealous of them and their selected durable materials

We would have the pleased to receive your inquires for our products. We pray for you and your company.

That's nice. I could use all the help I can get. I wonder who they pray to...

Awaiting your prompt reply

Don't hold your breath, Naveed

Best wishes,

Naveed

Export Manager

FULL SERVICE ENTERPRISES

Factory: G.T Road, Opp. Grid Station,

Wazirabad,52000. Pakistan

They included several links in the email to their website, but none of them worked, I guess because the font was so bizarre. I did hand-type the website address, because I just had to see. It was the worst sort of cheap junky crappy imported knives that you could imagine. I'm tempted to include a link just so you can laugh, but that wouldn't be very professional. Okay, if you want to look at them, drop me an email for a giggle. Oh, no! don't drop me that email. They've folded up their tents and are already gone...

Even though I've gone to great lengths to clearly state what I do and don't do, I constantly get letters and emails from folks who just need a little something. In the past, I've answered these, but at over 40,000 hits a day on this site at the time of this writing, I just can't afford the time to answer every request, inquiry, or question. I'll post some of them here, just to give you an idea of what people are asking. Remember that the people who've written have ignored my statement that says I don't answer questions or do research for other people, they've ignored my page clearly stating what I do. They feel they are special, and they deserve my attention and service.... for free. Okay, I'll forgive the kids... but if you look at every one of these, you'll notice that they are directly addressed on my "What I do and Don't Do page." But remember these folks are special! I haven't bothered to correct their spelling; if they don't care then neither do I!

Mr. Fisher: We are looking for someone in Albuquerque, New Mexico to hand-engrave an aluminum lamp. Where are you located? And could you do this? I look forward to hearing back from you. Thank you.

from a lawyers office! Must be too dark in there to read the website... wait, they would have to have a monitor-

I have a custom knife that I left in the sheath too long and the sheath

is a bit stained from the brass hilt. Is there any

way to clean the sheath stain?

Thanks. Weldon

I like Bright and Brighter Sheath Stain Cleaner. It removes the stain but leaves the frame, with a bright refrain. Everybody sing now...

Hi Jay...... This is a shot in the dark, but i am trying to find out about a custom knife maker named red royal. I have a few of his knives and cant find any info on them. I know he must be deceased by now, (too much grinding gave him lung problems). He used to do shows which is where I met him......... any help would be greatly appreciated...........Thanks........... Richard

Could this be Eric the Red? I saw him last frozen in a block of ice at the Curry County Carnival in 1974. Though the barker claimed he had been there for a thousand years, his face looked as fresh as a mannequin. Amazing.

I was wondering if you have a catalog and a price sheet fo different sizes of wood pieces you have for sale, use for knives and gun grip sizes? If you do have a printed catalog , please send to R. B. (*deleted*)Florida 33541 .I can also be contacted at (*deleted*) Thank you for your time and patience. Sincerely R. B.

It needs to be a printed catalog, because the computer monitor is hard to use to swat flies while parked on the throne. And a smartphone or a tablet just doesn't have the speed of #5 grade three-color magazine print stock.

Dear Mr. Fisher,

my name is Stelios and I am writing to you from Greece. I

am a collector of historical swords and swords from the Lord of the

Rings. I would like you to tell me if you are able to manufacture for me

a Byzantine paramyrion. It looks like a scimitar however, it has a

slight curve in comparison to Arabian scimitars alghough Arabs had

something similar to it. I would also like you to tell me how much it

would cost and I would also like to tell you that I want it to be battle

ready and what I mean by that is that I want it to have flexibility and

hardness at the same time. It is very important for me as a collector to

have such a piece in my collection due to the fact that allor most of

the swords which are being sold at the time by various companies are

not battle ready and are not made by hand. Finally, I have not found any

company that sells the particular weapon which I request.

Stelios C.

"Historical Swords and Swords from the Lord of the Rings?" You do know that it was just a movie, don't you? And you don't need one nowadays to be battle ready, as the last actual sword battle with the Byzantines was in 1204 AD when Constantinople was sacked. Maybe that was when the Hobbits were finally freed to return to the Shire. Did you know that Constantinople is now Istanbul? I learned that from "They Might Be Giants" on their album "Flood" back in 1990. We didn't bother to tell you.

Jay, I just wanted a quote on a Zebra Wood knife HANDLE, not the blade! Thanks again, R. M.

This was unusual, because I never gave this guy a quote for anything: knife, blade, sheath, or handle. Anyway, he's quite excited and screaming the word "handle" to me in his email makes certain that he is now the focus of attention on this very page.

i have a friend who also likes daggers and swords. id like to

get another cd for him. by the way, the pictures are really

good. i collect swords and daggers from bud k. i have the dark

demon slayer, dark demon dagger, hell guardian, and the crystal

dragon. i also bought some from a convienience store. im

working on 2 more swords.the address is: (*deleted*)

Thnx, Shadow

Ruler of the Darkness and Shadows. Master of the Night. Hater of

the Daylight. Lover of the Blood Red Moon.

Whoah! A nod from the dark master himself. I'd better comply else he'll set the demons of hell through my gossamer floor length sheers into my parlor whilst I repose on my Victorian velvet coaster.

I purchased an expensive very high quality Schrade knife 4 years ago

and now the handle is broken. I understand that you are the

designated person to honor the lifetime guarantee. I know that you

must be very busy, so I'll follow up with a call.

--J. A. L.

Little Rock, Arkansas

Why did I leave this knife manufacturer's name? That's because these knives are made in China. This company had a great beginning in the USA, but the name was bought out by Taylor brands and none of their stuff is made in the USA. They simply bought the name "Schrade," in order to make money from it; the actual cutlery company is no more. Perhaps someday, the Chinese will buy the name "Jay Fisher" to sell their crap. Then, these requests will be non-stop, and I'll have to change my name.

Hi my name is R. P. I have been looking for the master sword, Legend of Zelda Ocarina of time. At this time I can't send pics of the sword because the scanner doesn't work, so when it does I'll send some. I have a lot good pics for you to go by and a pic of the hilt that I hand drawn my self. I just got finished reading most of your web page and I'm flabbergasted at the prices but being a kid so to speak I think I might be able to pay (I hope) although I'm at making money I'm afraid it may take awhile hmmmm. I'll send the details as soon as I can .I'm using my dad E-mail so E-mail him and I'll get it. Thanks for your time

Don't take Zelda seriously, kid. Miyamoto and Tezuka didn't bother to finish their swordmaking classes, and instead focused on programming, which paid off for Nintendo in a grand way. I hope those guys got their royalties; but probably not. My advice is to get with the real world; where Zelda is the hot chick that works at the diner around the corner. She's a legend alright, and she has her own email and not her dad's.

I was wondering if you could give me a quote for this knife design

here are the specs

I was wondering if you could give me a quote for this knife design

here are the specs

Knife thickness 1/4in knife length 161/2 in knife steel 1095 high

carbon alloy steel RC58 --first blade-- (dark gray) Grind flat

thickness 1/4in length 31/2 in --second lade-- (light gray) grind

convex length 3 in thickness 3/16 in --double milled Saw back

blade-- length 4 in --handle-- length 6in material thin layer of

hardwood

Here's a quote for you:

“To invent, you need a good imagination and a pile of junk.”

--Thomas Alva Edison

hi, i'm nobody i'm not going to say that i'm the metal king of

metals. even know this has little to do with metals ... ok let me

start over.

i'm "nobody" this is a question about a sword ... kind of. you see

i'm makeing one a japanese looking one the only problem is the

handle they told me $275.00 for a rayskin handle with the 2 metal

ends ( iron would be nice ) and the hand guard. now the sword is 1/2

in. thick by a 1 in. It normal steel i made as thick as possible

with out being to heavy. any how the handle please tell me you can

make a rayskin handle of some type for less. Its a home made sword

it should cost that much. i ask because the link said u could when i

looked up sword handle.

please reply, thank u,

"nobody"

He's not "nobody;" he has a name on his email...sigh

Good Morning: I have a knife as follows:

Could you indicate your interest and value.

Thank you

D. P.

Interest: insignificant

Value: pitiable

Guten Morgen!

Cleaning out my dad's closet I came upon a knife made by the Sidney

R. Baxter & Co. of Boston. Carbon steel, rusty

and corroded. How can I best clean and get in

good condition. I see you want me to use silicone car wax, but what will

first stop the rusting? Thanks for your time and expert advice.

Rmb

"I want you to use?"-

Have we had a conversation? I think not! You are referring to my knife care page for

preservation of my works. Perhaps for your special knife, you could use the entire car,

carelessly driven over your knife again and again. The abrasion of the

asphalt on the

carbon steel will eventually remove the rust. Don't forget to invert your knife

occasionally

so that both sides are able to benefit from the gritty abrasion. Multi-ply steel

belted radials can ensure that this will work for years to come.

This is not a knife I have but I do have some

that are similar. My question is what are the ridges on the top of

the knife and what are they for. They don't seem sharp enough for a

saw but so many knives have them like this. If you could tell me

what the heck those ridges are, I would greatly appreciate it.

-db

Back in my day, Rrrrufles had rrrridges, not knives. Quite tasty, too, they were!

I will be recieving an elk horn and plan on using it for a full tang

bowie. How do you prepare a horn for use as scales. I have never

worked with that type of material before so I would appericiate

any advice you can give. I was planning on splitting the bone into

and do it as I would wood. Will I have to fill the inner pours or

stabilize it? Really lost on this one Jay. Thank you,

T.

Ahh, an important topic. Elk horn has a delicious flavor when steeped in Thunderbird wine for 3-4 days. You can also slurp up the wine through the pores in the center of the horn, just like a peppermint stick in an orange. The girl scouts taught me that while we were all sitting around the campfire with elk horns, wine, oranges, and peppermint sticks.

Good Morning Jay, I am contacting in hopes of getting some

information of a large knife collection that I am going to sell for

an estate. The man's name was R.F*** he

passed away and his wife is wanting to sell his vast

collection...all purchased through the K. G. The

person that I am trying to contact is J. W*** her

last address was Utah. The phone number that I have at the present

is out of service. She is an engraver that has engraved a number of

the knives that we have to sell. I thank you for your time and hope

that you can help me with my search. I can send you pictures of the

knives that I have to sell if you wish. Thanks so much.

P.

Just what information does this person think I have? Oh, I forgot; part of my service to this industry is to be a clearinghouse and reference for all things knives. Here's a scoop for you; I heard a rumor that the flouncy engraver took up with a knifemaker and and broke up his marriage. After numerous bouts of binge drinking, a couple DWIs, and court mandated community service work, Utah got even. It's a good story, anyway.

Hello,I read through your "What I do and Don't Do" page, and I

didn't see my question listed. I am in the process of leaning to

make knives and swords, but have hit a snag. I bought some 2" thick

steel to make my own pommel, but my bandsaw wants nothing to do with

cutting that. Would you make a pommel if I provided a sketch with

dimensions? Thanks so much,

C. G.

I have pommels for sale on my pommel page here on the site. I've got them made of polyester/spandex blend, metallic ribbon and hot glue, with ric-rak stitching around the base. I've also got plenty of toories, bobbles, and floggers to accentuate motion, attract the attention of spectators, add sparkle, and attract the opposing team so they make a mistake! The French navy would be very proud of my selection and flair!

hello JAY,I wanted to know if you have a paper catalog of the swords

you make,If you have one could you send it to me?and one more

thing,do you know where can I study or learn how to work as a swordsmith

like you?well,that's all what I wanted to ask you.thank you.

G.C.

What is this fascination with paper? I heard back in the 1970s that we were going to a paperless society! You can't have my paper, I'm hoarding it all for the apocalypse. I store it in my spider hole hidden in the mountains.

dear jay:

Absolutely amazing work you

do................I can't say that I am into knives all that much but I

was wondering if maybe you could help me with a question I have .

Nepherite from B.C. The dark green and real heavy kind.......Well I have

a piece it weighs approx 80-100 lbs do you have any idea what it would

be worth? This piece came from Ogden mountain. Well I just thought that

i would ask as I really have no

idea......................................sincerely yours

k. c.

Wow, that's some really old nepherite, way back in B.C. What is that anyway, the egg of the nepher? Anyway, I can't be expected to know the value unless it's incubated and the little nepher is crawling around your feet. Send pictures of him doing funny things: watching the TV, staring down the dog, and splashing in your kiddie pool, and I'll post them for everyone to enjoy.

Hello, I am a french studient and I would like to ask you how and

where I can learn the art of making knives...Do I have to learn with

an artisant or can I learn it in a school ?

Thank you very much for your answer

Shouldn't you be asking this question in French? That's what our Spanish teacher told us to do: practice, practice, practice; use the language to become familiar. That way, you'll know the difference between a Laguiole and a Sabatier.

hey my names matthew and i am 15 i just started really getting

into knife building and i admire your work as in mine is not as

great. i only have a benchgrinder and one inch belt sander to

make and sharpin my knives but i would like to upgrade tools

i really like making knives for people. all my friends have at

least one knife i have made but the only way i can make knives

now is grinding every single blade out by hand do you have any

sugestions for me about what to use and what i might try. also

i was wondering if i could use some of your knife patterns to

make knives with.

matt

It is truly sad that most high schools have suspended or cancelled their shop classes. When I was a kid, you could make your own knife project in school, with the guidance and oversight of a big shop teacher named Rufus McCoy who wielded a custom-made paddle if you got out of line. You could hear the wind whistling through the holes in the plank just before terminal contact... anyway, he would be able to tell you that a bench grinder is not the machine to make a knife with; it's dangerous, and it's the wrong tool. I suppose one good thing is that modern schools still allow you to read books on shop safety. But I'd bet they would ban a book on making knives...sigh.

Mr. Fisher,

I just wanted to tell you that your work is quite exceptional. I found your site when I

was doing a search for embellished knives. I am just learning to engrave and carve and

it is always interesting to see what others are doing along those lines.

My husband makes knives occasionally and we enjoy the beauty of a well made blade.

I started reading your first page of funny emails you posted and decided after reading the

first page I should stop as I was laughing too much.

Your knives are quite beautiful and I really like the engraving you do. Not everyone

likes the 'flowers and scrolls' and that doesn't always fit the weapon anyway.

Anyway, just wanted to let you know that I will use your pictures as inspiration to do

my own kind of work. Thanks for sharing your work.

Sincerely,

Sue Schroerlucke

Sidney OH

This one deserves its own dissection and analysis, since it covers so many subjects that I don't have time for, instead of just one or two that I don't have time for:

Hi Jay. I've been cutting stone for quite a few years and about 4 years ago I decided to learn silver casting.

This is somehow important, since I'm the source of all things cast in silver. Sigh.

I don't want to make swords.

I don't want to make beaver tophats, myself, so I can understand your predilections.

I used to cut opals, but right now I'm satisfied with pendants, broaches, and rings, plus bracelets have dominated my jewelry thinking for the last several years.

I don't castrate young bulls, though I used to when I worked on a ranch as a child. I also picked corn, pulled careless weeds, and helped de-horn the stock. Right now I'm satisfied with simply having a good steak now and then, and that has dominated my farm and ranch thinking for the last several years. Why are you sending me this email?

I have a Grobet vacuum casting machine, and although it works okay for outgassing investment and RTV molds, the casting side is a nightmare. Almost 4 years of wrestling with it and I still can't reliably cast. I saw your page on Rodger's Sword while I was investigating centrifugal casting machines. I've used a centrifuge a few times in the past, but I wanted to ask you if they could *really* handle a 4 x 6 flask, which it looks like you are using.

Oh, I get it! You saw some familiar piece of equipment that you recognized, so we must therefore be brothers in blood. Would you like to know my brand of television, the toothpaste I use, or the grocery I shop at? Then, if they are the same, we will have a greater bond than identical twins separated at birth!

It also looks like you are using the Rio Grande centrifuge, and that's the one I was thinking of buying.

Seriously, dude, I get paid big for my endorsements. I can't offer one for free; my agent would freak.

About your Werewolf carving, I wondered if you have gotten into 3D modeling and 3D (CNC) printing? Computers in general are such a pain in the etc. that I don't really recommend them, but if you are already into computers it might be something to investigate. You can create a model in a 3D graphics program (I use Poser version 4, which is ancient) and send the data file to a company that has a 3D printer (such as stereolithography). A few years ago prices were something like $100 per inch, but since so many people have 3D printers now, I'm sure it's cheaper. They send you a 3D plastic part that looks like what you created in the program. You could then make a mold of that part and have lots of wax copies to modify and experiment with. It would be a huge time saver if you were going to use the same part a number of times in the same design, or over time. I'm attaching a gif of the Poser wolf. Of course, in Poser, this is a true 3D object. You can move its head, eyes, neck, paws, etc. I think the Poser program is now up to version 8, so they probably have a better looking wolf.

Just what every artist wants: a computer-resident model of someone else's artwork. That way, you don't have to actually create; it's like clip art, you just point and click. The great masters never had it so good! Dude, your tediously detailed explanation takes longer than it would take to sculpt it myself! Maybe they'll make a brain scanning machine so powerful and versatile one day, that all you'll have to do is think of something and it will be created! Wait, what about all those bad things people think of... maybe that's not such a great idea.

If I ever get a digital camera, I will take some pictures of my opal inventory and maybe you will trade me a nice knife for a nice opal. -D.

If I ever get a pencil, I'll draw you a map to logical reasoning. Your train of thought seems to have left the station. I'm glad we're wrapping this up with a solid idea, plan, goal, or inquiry. Sigh.

Hello,

my name is sarah H. Right now i am studying at unitec, it's my first

year and i am doing the 'certificate in design skills'.

One of the feilds that we are studying is product design. in product

we have a final assignment, which is to re-design any knife of our

choice. i have chosen a cheese knife( the kind that has the folk

type end.)In this assignment we are required to write a report on

the manufacturing processes and materials used to produse our

selected knife. I have searched the internet as far as my

paiteints will take me, and haven't found anything of any use to me.

So if you could please send me as much(the more the

better) information on the processes and materials of a knife it

would be greatly appretiated. Thank you,

Please write back, ASAP

sarah

Really, Sarah? Studying at a higher level institute of technology ? You should be studying English first, or minimally, using your tech skills to invest in a spell checker for your email. And the project (redesigning a cheese knife)? How fascinating. Like cheese can't be cut with just about any knife including a dull butter knife. The reason you haven't found any information on details of cheese knife design is because the whole world is bored with cheese knives. And to focus on their manufacture? Well, I can't think of anything more boring. The topper is that you want me to provide all of the information possible for your pet project. I'm disappointed. You're young; you need to get out more.

Hello Mr. Fisher,

I hope you do not mind me putting you a question.

My name is K. K. I am a hobbyist

knifemaker in Czech Republic. The other hobby

I have is collecting minerals and semiprecious stones.

This is the reason I immediately started admire your work when I

first saw it on your webpage.I have a little

project in mind and would like to ask you for advice.I would be very

glad if you can share your experience with me.I am doing a knife for

myself. I have a damascus scandi type blade. Ihave been thinking about

using flat piece of red jasper for a bolster

on this knife. My first question - do you

think this is generally a good idea? I think

about possibility of chiping the bolster, but I am not sure

about it. Second question - can you

give me some clue how to make square hole for

the tang in the stone plate? Which toos you use. I have a dremel

and some diamond cutting wheels. and some diamond dental

attachments. But the tang hole is a tricky

work as it has to sit flush on the tang and

ricasso. Moreover there is small radius where

the blade goes to tang. I would like to make the hole in

the bolster perfect. How you did the handle on your "New Orleans"

Dagger with the Green Aventurine, Rare Blue Aventurine spacers?

I have a friend who cuts stones with diamond wheel and polishes

them. He can make me the plate of jasper.

Sorry if this email is going to bother you.

Thank you in advance,

K.K.

I don't mind answering questions from hobbyists, look over this very page; you get the idea. To make a square hole in a stone plate, the "toos" I use are Tovax 100 water gel explosives with #6 blasting caps. Use plenty of precautions, because it will leave a smoking crater about half a meter in your garage floor, and you'll have a hard time parking your Škoda.

Remember, in order to email me, these people have completely ignored the page detailing what I do and don't do. They can't email me without seeing the page link. The scary thing is (as one friend reminded me), these people might vote!

Hello sir, my name is J.M. I am 24 yrs

old and have always enjoyed the art of creation since I was a

young boy. Iv always been interested in the beauty high polished

rock and minerals, metals, and even glass. But lately Iv been

really involved in the creation of knives, and has developed

as my dream to start a knife business.I am currently taking

scrap metal from an arbor shop I work at to make knives. I'd

like to thank you most of all for the freedom of your work to

the public and info you've provided on your website for all the

knife hounds out there. you've been a great inspiration to the

beginning of my new legacy in knife making. So to get to what

I've been waiting ask you is, as a beginner in knife making, I

was hoping you could spare me any of your knowledge as to how I

could get started cheep. At the moment all I have is a 4 1/2"

right angle grinder and a 16" bench grinder. What do I need. Id

also really appreciate it if you could send me your brochure.

p.s. your distant student j.

My humble thanks for your glowing encomiums. I don't know how you could get started cheep, because my cheep may be different than yours. For instance, I think the Silver Laced Polish chickens look regal in their gray beards and muffs, but the Salmon Faverolles are quite spiffy trotting around the shop in their fuzzy little boots. For a beginner like yourself, I would suggest a small clutch of Silver Duckwing Yokohomas. Their long tails will grow as they mature, and clean up all the swarf and dust coming from those grinders. Just never mention the word "Colonel," even in jest, as they are quite sensitive.

Jay,

I am wanting to make my first high quality knife. My

question is what type of steel would you recomend to make the blade.

I will be using this knife for skinning animals (Elk,Deer). I would

most likely do some whittlin of sorts with it. I obviously want the

blade to hold an edge for a while. I am thinking of 3/16" thick D2

tool steel. Is this something you would recomend? Do you have any

thoughts on Titanium? Also I would like to know what you would use

to attach the scales to the full tang blade (Pins, ect.).

Thank's in advance, Charlie

High quality whittlin and skinninin of sorts. Back inninun the woods. Yup.

Dear Jay Fisher:

My name is T. M. I

attend Douglas Anderson school of the arts. I am doing a research

paper on sword/swordsmithing,and l need professional to interview.

If you could answer a few question for me, l would greatly

appreciate it. And if all possible, could you respond by 03/01/04.

Thank you very much.

Thank you very much for your time.

T. M.

PS. May l quote you in my report? thank you very much.

Why not just have me write all your course reports, essays, and perhaps a thesis? That way, you wouldn't have to do any research whatever, just turn in the reams of paper I create for you and go back to skateboarding, video games, or whatever else you do when you should be in school! Seriously, and then include a deadline? What kind of young people are we raising?

Mr. Fisher, Hello my name is B.N. and I am a 17 year old Missouri native that is just getting into knife making. I have made a knife out of an old lawnmower blade and enjoyed it a great deal. I am about 70 percent positive that I am going to go into the military after I graduate high school with aspirations of becoming a Green Beret. Therefore I would like to try to make a knife that I can carry into battle with me. If you would not mind could you give me ideas of what type of a knife would be best, what materials to use from start to finish and where to get them? Being a novice at this trade and knowing that my life may very well rest in the quality of the materials and shape of the knife I don’t feel comfortable making these decisions. Thank you for your time and I hope to be hearing from you soon.

I think you should continue on with the mower and adapt it for combat. Maybe you could stand it up so the Briggs and Stratton is whirling those knife edges forward, toward the enemy. You could initiate the "BS Brigade," with self-propelled, auto-primed, mulching sickle-flails devastating the fields of battle. And in your spare time, you could earn a few extra bucks cleaning up the neighborhood.

I'm a student at k. midlle school

in Eugene, Oregon. I am researching knifemaking as a career

and I am hoping that you can take the time to answer a few

questions for me. If that's OK you can just reply to Mr. N.,

my teacher, whose computer I am using. If you don't have

the time that's OK.

1 Why is this career important to our society?

2 What kinds of people do you work with when you do this career?

3 How do you work with them?

4 what are the most important tools?

5 What is the most fun about knifemaking?

6 What is not fun about knifemaking?

7 What is your favorite thing in the job?

8 Did you have formal training if so what?

9 How did you learn your skills?

10 What kind of materials do you need?

11 What kinds of knives do you make?

12 How do you make really strong swords and knives?

13 Which do you prefer to make, sheath knives or folding knives? Why?

14 What are your favorite handle designs?

15 What are the basic steps in making a knife?

Thank you vary much from K.B..

Sure, K.B., I'd be glad to write your essay for you. Please give me a detailed reference list including journal articles, conference proceedings, books, dissertations, company reports, web references, and any personal communication and experiences that relate to your subject. Don't skimp on the details, I'll need dates, locations, and a complete bibliography of references.

Hello Jay, I have not had the opportunity to own one of your knives but would

certainly like a catalog if you provide them. The reason for this email is that I have

purchased 2 Randall knives that I got through eBay. Although they advertise they were in mint

condition I have found it is rarely the case. Anyway one has signs of pitting from what I think

is rust then it was cleaned up and a heavy coat of oil was put over the blades so the blemishes could not be

seen by the photos. Regardless I am happy to own the knifes but I need your advice in

how to clean the blades up, both have scratches from improper sharpening and as I

said before some pitting. I am hoping you may know a trick or two on how I can remove

these scratches etc and get them in a much better condition, it bothers me that

a great tool and a work of art has been treated badly considering the work put into them by professionals like

yourself. I do not know much about knives, just that I enjoy a very good quality tool that is dependable and I

like taking care of them also. I have not much experience making knifes just a little

stock removal from planner blade that I know are very high carbon due to not even being able to get any drill

to get a hole in it. I know ,I have to get the temper out first but I should of thought

about that before trying and breaking a couple expensive bits. One more question.

I just bought an 2x8 EZE LAP diamond stone, is this a proper stone to use on all my knives?

Thanks Jay D.

P. Post Falls, Id

Not knowing all of the knives you have, I cannot recommend any stone for them. Please give me a detailed list of every knife you've ever encountered, seen, or even thought about. I'll need specific measurements, types of materials, condition and exposures, and a complete folder of provenance with all the addresses intact. Most important is the measure of each scratch, no matter how small. Please describe each one, its location, depth (in microns), width (in hundred thousands of an inch) and length (in road apples from the Cayuse Indian Pony breed).

Dear sir

Staghorn is prohibited as per Wildlife Protection Act in India. What

about united states. please give your comment.

Thank you,

Satish p.

Grups! Bonk, bonk on the head, bonk, bonk!

Remember, in order to email me, these people have completely ignored the page detailing what I do and don't do. They can't email me without seeing the page link. The scary thing is (as one friend reminded me), these people might vote!

Wich is harder rwl-34 or damascus? And wich would make a better knife that keeps an edge and will last longer? Thank you.

Wich wich is a sandwich, and wich wich is a Wiccan wich?

Dear Jay, I am sorry to bother you, but you seem to "know

it all" I found a website that

showed about four or five ready-made hidden tang

handles, like jigged bone, wood, etc.but I have spent

a few hours over the past few days, trying to re-find it. I

have found several that I have seen before, Northcoast,

Jantz, TKS (one of my favorite places to buy materials

from), Alpha, Crow, "Jagermeister" (sp?), Track of the Wolf,

and I still will be danged if I can find it, they had an

excellent supply of guards and

pommels, most sell handle scales, but this one had hidden

tang handles any ideas of which

website I am seeking, which company?

Lewis

I recommend buying from Blockbuster, Hollywood Video, 4Kids Entertainment, or Hostess for a modern look. Perhaps you should buy from Montgomery Ward, Home Base, Polaroid, Pets.com, or PanAm. What did all these companies have in common? They all failed because they called me a "know it all."

I am wondering how to identify two swords I have

acquired that have been in my family for many years. Is

there a good source you can recommend?

Vicki

Your eyes are the most useful, just look for a long blade and a short handle.

Mr. fisher i was found this dagger during the reconstruction of my house.

Dagger was burried deep into the ground. I wonder if he has some value or it is just piece

of junk. Sorry for bad english.

M.

You didn't say whether or not it was near that recently poured slab in your basement with the hand sticking out. It might be worth quite a bit to your local CSI or Crimestoppers.

Dr. Mr. Fisher,

Hi. I inherited from my father several very

interesting edged weapons. I have minor knowledge of

this sort of thing. I thought just maybe you could help

me. Do you know German? Neither do I, but I tried to

translate what is on this one weapon.

Why would you ask if I know German and then claim "neither do I," as if you already know that I don't know German? Are you having an assumed conversation with me in your head? Dumme verrückte person!

I am an Artist and amatuer photographer. I seem to collect just about anything that interests me.. from fishing lures to all this WW2 stuff my Dad gave me thru the years. Dad passed away last April at the age of 90. Dad inherited these things from his 2nd wife (my stepmother) whose first husband was a surgeon (he died in 1971 at the age of 77) and also in WW1 and WW2.

I smell a hoarder.

I tend to believe this one dagger (and I am not sure it is even a dagger but don't know what else to call it) could have been the Dr's father's. Are you with me so far?

Nope. I got lost in all the clutter and tedious details.

There is so much engraving on it for such a little thing you just wouldn't believe it! I did take photo's of it and the others. Can you help me? Such a mystery! May I send you the photo's.???

I've really tried, but I just can't experience your level of excitement. Yawn.

I send Jpeg and everything goes thru my NOrton internet security and if you can enlarge to see them- ?? I could send large but won't do that unless you say I can. The other 2 weapons I have are a captured Nazi dagger and a Werth looonnnggggg sword. Also photos.

Never got it; don't want to see it. However, I would like to hear the story of how the Nazi was captured.

Plus would you please tell me if you get this

email? Thank you.

Sincerely,

K.C.

No, I don't want to encourage you to send pictures of your questionable war booty.

Dear Mr. Fisher,

I am writing a book on Thomas Jefferson, and in one

of the family letters there is a reference to a large

hawksbill knife.This was in 1819. Can you tell me what

such a knife would have been used for, what one might

have looked like then, what would have distinguished it

from other knives? Thank you,

A. C. Richmond, VA

Will I get a portion of your royalties, or are you just going to use my historical reference services and then toss me out like an old shoe? You could at least offer me some Jeffersons for the reference work. About 50 would be nice.

ill like to ask where can i perchase s30v steel so i could shape my own knife... do you know if i could buy them in texas? tnx...

Jay,

I was wondering if you may be able to answer a question for me. My

husbands father was in the military during WW II 1944. He was presented with a gift from a man in his

barracks. It is a double sided dagger and was handmade by, this boys dad, a fellow with the last

name of Perez. We cannot make out the first initial. ( ? P. Perez )This dagger

is 70 + yrs. old. It also has a leather sheath that covers it. The

sheath has Mexico pressed in it. The handle of the dagger appears to be some sort of metal that

doesn't tarnish, possibly nickel with a bone, ivory or agate insert. It also has an indian carved head

at the end of the handle. I'm not sure what tribe it represents. I would

appreciate any information that you may have.

Sincerely,

J. H.

This is the most common sort of tourist trash that comes out of Mexico. People actually ask about this a lot, and you'll see this type of knife mentioned on nearly every one of my funny pages. Go to Juarez, and you'll see hundreds of this type of knife, each selling for pennies. It's not even worth what the email cost to write and send, and that's free! Except for your time and mine. Maybe we will help someone else who has this tourista crap and thinks it's worth something.

Hello Mr. Fisher...I am hoping that you can help

identify a knife that I have recently aquired, or

perhaps point me in the right direction. I've attached a

pic of the knife. Thanks in advance.

Steve

I looked at the pic: yes, I do think that's a knife, right there.

While searhing for information on steels and the qualities to look for in knife blades I happened upon your sight. COOL, I like what I see and was wondering if you have ever made a knife with a gut hook or just a gut hook? I have yet to find a gut hook worth a dime. When field dressing a moose it would be nice to find one that works. thanks for your time:

Last time I field dressed a moose, I did it with a sharpened toothpick. That was after I wrestled him to the ground while wearing my Dorfman hunter plaid hat, my rubber camo waders, and my tee shirt that says, "I have a big rack."

Mr Fisher I am a young man that has always been

interested in the making of the sword. I have no background in the

art, but I would like to know if there are class that one should

take. I have never seen one at the school's high school or collage's. What

should one do if there wanted to make a life of making swords. In your

opinion who is the best sword maker(now or in the past.) thank you for your

time

K. T.

The making, the art, the collage, it's all so culturally rich. I'm getting out my glue and scissors. Do you have any string?

attached is the pic of a dagger found in a vacant land

in the coastal regiond(west) of puerto rico it was found

25 years ago by my friends dad, maybe you can help me

with this . is about 12 inches long and it appears to

have a cat (jaguar type) handle .any kind of info wold be greatly apprecciated .

Thank you

E. T.

No, E.T.! Not the tourista crap from Mexico... again!

To: Technical Staff Hello Jay

I have worked as a Journeyman Industrial Blacksmith

as well as a Historic Blacksmith. Unfortunately I entered

the field in the late 70’s. By then, Industrial Blacksmiths

were just about extinct in the U. S. The Master Smith

retired from the foundry that I worked in due to poor health

and I was not blessed with his instruction when I started.

My question is: How were the old fashion Wood Saws

formed, heat-treated and tempered?

The good ones were hardened through the entire blade: Yet;

there was no warp, twist or ‘dimpling’. If you could

research your heat-treat information and share the

information with me I would greatly appreciate it.

Sincerely;

V. R.

Since you addressed this to our "Technical Staff," I'll put on my bright blue polo shirt that is embroidered "Technical Staff," and answer this email in methodological, scientific, and specialized clarity. This conversation is actually a good example of why the very best high performance knives are NOT hand-forged. He says that "industrial blacksmiths are just about extinct." Why do you think that is? In modern industrial settings, the steels and their processing are done by machinists, not blacksmiths. Blacksmithing is a generalized craft, and an open forge cannot specifically control alloying elements that are resident in the highest quality modern tool and die steels. These steels must be treated in high purity, or at the very least, controlled environments. The open forge allows contamination, decarburization, and uncertainty of critical exposures, therefore, is not used with the very best modern steels. Industrial demands are high for quality, certainty of process, and verifiable results that are specified in modern machinery needs. The blacksmith can not supply any of these. This is why there are no hand-forged ball bearings, hand-forged shear blades, hand-forged industrial machine dies, hand-forged shafts, races, gears, or fasteners. When was the last time you heard of a hand-forged turbine blade? A hand-forged car axle? A hand-forged pressure vessel? Come on, folks, what does it take to understand? The very best metals are not and can not be hand-forged! Look up blacksmiths and you'll see many wonderful products they supply, like small craft items, architectural railings, guards and balconies, tools for other craftspeople, artwork, and decorative knife blades. Just don't ask the blacksmith to produce industrial quality high wear, corrosion resistant, or extreme use parts for machines. I even use hand-forged pattern-welded damascus steels for knife blades on occasion, but make it clear that their value lies mostly in their appearance, not their function. Okay, sorry, that wasn't funny, but I needed a touch of reality.

Was just reading over your sight; the part about not

storing knives in their sheaths. I heard the tannin in

leather interacts with the stainless steel to form "pitting"

in knives. I've seen this . I also can

understand the idea of knives needing to breathe and

therefore would rust..

I recently purchased some knives from a company in

Finland. Their sheaths are lined with a stiff plastic

liner and the manufacturer says, always store your knife in

this sheath.Have you ever thought of cementing a

plastic liner into your sheaths? Apparently it works.

If you already heard of this, do you have any idea where one

could purchase plastic liners?

Your sheathes by the way are beautiful examples of

craftsmanship. I was looking for a simple sheath for a

dagger. I can't afford yours although I'm sure they

are worth it.

Do you know what those trendy car bras were for? To keep your garage from getting pregnant.

Hello, my name is R.C.

I'm hoping I came to the right place for this. For

years, I have been fascinated w/ a sword from my childhood.

I have always wanted a replica of He-man's power sword, like

the one used in theoriginal 1980's cartoon classics.

I searched online for someone that has either made one, or

someone that could custom make one. I did find a

sword, but it's modeled like the one used in the new He-man

series. So I was a little disappointed!!

Here is a picture of the sword.

I have more pictures of it, if needed to show more of the

dimensions, and even cartoon footage that really shows the

depth. Now the true size of the sword, I really can't

say how big it should be. I guess you'll have to

compare him to a real, person, and start from there!!

Also I'd like to custom make She-ra's sword. It's

basically identical to He-man's except hers has a jewel in

the middle of it. It's like a clear or very light blue

jewel that goes through the center and is visible on both

sides of the sword. I do have pictures of it too.

Well I hope you can help me w/ this. If not, maybe you

know someone that can. I've searched for a long time

for a master sword smith that can bring this great legend to

life!!! I knoww there are a lot of people that wopuld

love to own this sword!!!

I have more pictures of it, if needed to show more of the

dimensions, and even cartoon footage that really shows the

depth. Now the true size of the sword, I really can't

say how big it should be. I guess you'll have to

compare him to a real, person, and start from there!!

Also I'd like to custom make She-ra's sword. It's

basically identical to He-man's except hers has a jewel in

the middle of it. It's like a clear or very light blue

jewel that goes through the center and is visible on both

sides of the sword. I do have pictures of it too.

Well I hope you can help me w/ this. If not, maybe you

know someone that can. I've searched for a long time

for a master sword smith that can bring this great legend to

life!!! I knoww there are a lot of people that wopuld

love to own this sword!!!

Thanks for your time,

R.

jay i am looking for a custom sword to spark fire in my

eyes every time I look at it.

Suzanne E.

Hi, Just a quick question. I'm

looking to make my own custom knife, but have no experience at bladework. I dont need any of the wood

or gems, just the metal. In essence just the sharp metal. I'm looking for 440c, 3 inch

blade with a 4 inch tang. A quick price estimate would be appreicated.

Thanks

Here's another credit card scam inquiry. They want whatever products I'm stupid enough to send to them, they have a stolen credit card, and are ready to rip off the stupid American knife maker. To address me as Dear turns my stomach-

Dear,

We are from Singapore. We have a plan to order some products from you. Can

you ship to Singapore via FedEx, UPS ? If you can, we would

like pay my order with credit card, are you accept credit card ?

Please confirm us as soon as possible.

Best Regard

Here's yet another credit card scam inquiry. Do you suppose I get lots of these? Yes, I do, and they're all pretty much the same. They don't know or care who I am, or even what I sell. They simply mass email to web and email addresses hoping to snag some prey on their hooks. The questions alone give them away. "Just send anything, we'll be happy to give you a stolen credit card number and get anything we can to sell on the black market." I left the guy's name on this one, but it's probably an alias...

Dear Sir or Madam,

I am looking for website and i want to order your Product,

But Before I continue my order, I have some question below :

1. Can you Ship to Singapore ?

2. Do you accept major credit card as the payment ?

3. Do you use shipping method for FedEx or UPS freight service?

I'm waiting for your confirmation as soon as possible.

Looking forwards to doing bussines with you. Thank's in advance.

Best Regards,

Dennis Jocelyn

Singapore

they don't want to bother with a lot of email and back and forth information or details about their order; they just want to know if you'll be gullible enough to send them some stuff

Here's another block of emails from folks who have completely ignored the page detailing what I do and don't do. They can't email me without seeing the page link. They either don't care enough to read it, or don't think it applies to them.

Hi Jay,