Jay Fisher - Fine Custom Knives

New to the website? Start Here

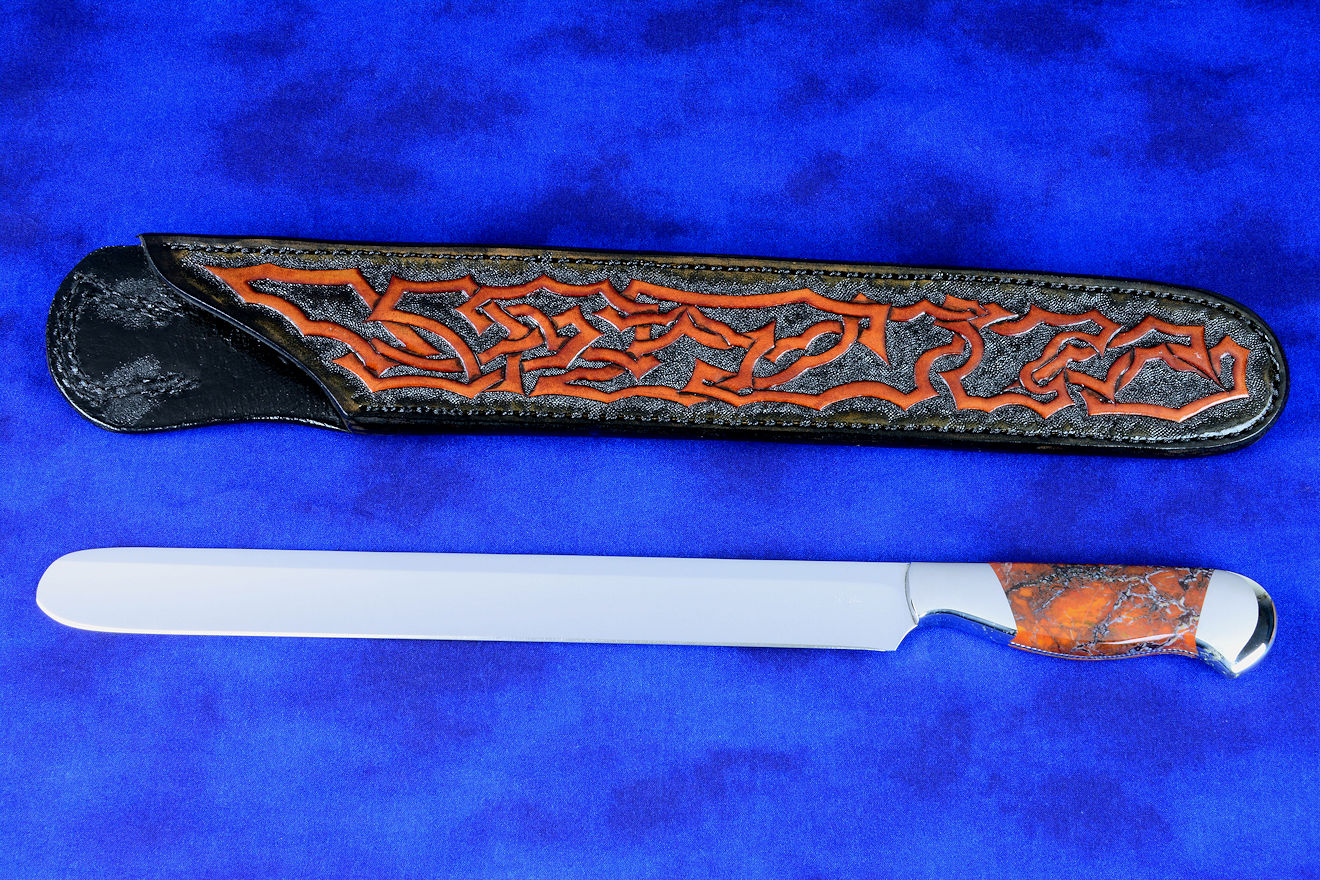

"Cassiopeia"

Right now, you are reading the best singular knifemaker's website ever made on our planet. On this website, you will see many hundreds of defined knife terms, detailed descriptions and information on heat treating and cryogenic processing, on handles and blades, on stands and sheaths, and on knife types from hunting and utility to military, counterterrorism, and collection. You can learn about food contact safety and chef's knives, you can find out what bolster or fitting material is best for each application and why. You can lean about caring for a knife, you can see the very largest knife patterns page in history, with many hundreds of actual knife patterns and photos of completed works. You'll also be able to see thousands and thousands of photos of knives, knifemaking, processes, and creations, with many hundreds of pages of appropriate, meaningful text. You might want to know why a knife blade is springy, you might want to know why a hollow grind can last longer than a flat grind. You might want to learn about some pitfalls of the tradecraft, and you might even want to have a chuckle about funny and strange email requests.

You'll find all that here, on JayFisher.com, and you won't find it anywhere else!

There is nothing wrong with cheaper, lower-performance knives, and here you will learn why they are inferior, and what the cheaper knife sacrifices in condition, and thus, function.

It's extremely important to know that the processing of the steel during heat treat is one of the largest successful or detrimental factors in blade steel performance. Along with blade shape and geometry, the knife blade's performance is a result of the knifemaker's understanding of and expertise in steel heat treating process. While people in this field often generalize the relative performance of steels based on anecdotal tales, amateur testing, and popular gossip, most inferior blade steel performance is based on the geometry of the blade and the processing during heat treat. Many steels perform well, and properly processed high alloy steels are the very best steels in the modern world.

"Because tool steels are generally heat treated to make them adaptable to the intended use by enhancing the desirable properties, the behavior of the steel during heat treatment is of prime importance."

--Machinery's Handbook for the Mechanical Engineer, Designer, Manufacturing Engineer, Draftsman, Toolmaker, and Machinist, 1914-Present

Thanks for being here. I created this page as a service to my community of knife enthusiasts, knife collectors, users, aficionados, and knifemakers. I am certain that after you read this page, you will have a greater understanding of modern, high alloy steels used in the finest knife blades, and how steels are physically processed to achieve the very best knife blades ever made in the history of man. We are lucky to be alive in a time when this is possible, and when knowledge and research are available for free—for the advancement of mankind—in an instant.

What I want you to learn from this page is what modern, high alloy, and stainless steels are, what role they play in the world of fine knives, and how heat treating and processing works in my professional field. There is a right way to heat treat knife blades, and it has taken me decades to achieve the level of understanding I have in this field. There is always more to learn, and—God-willing—I'll continue this journey until I'm finished with this world.

Heat treating is the foundation of knifemaking.

I also want you to know what this particular part of knifemaking is not, and what misleading and erroneous ideas are still prevalent, and how inferior and antiquated processes, ideas, and steels are being hyped as of some value other than superficial appearance and tradition. I want my clients purchasing knives because the knives are the best they can possibly be, and that starts with the finest, most advanced metals and treatments that bring them to the pinnacle of their performance.

What kind of performance am I writing about? The performance of knives is cutting, cleanly, repeatedly, and continually. Simple enough; any piece of sharpened metal or other hard material will cut. The performance issue is then about durability, longevity, and strength. These characteristics exist not only in the design of the blade, but also in the steel alloy itself, with advanced metallurgy, scientifically treated, for the highest wear resistance, toughness, strength, and corrosion resistance. This is the working end of the knife, the cutting edge, and performance has to be built into the blade alloy and brought to its most effective physical state by processing, typically done by the knifemaker himself.

"There never was a good knife made of bad steel."

--Benjamin Franklin

A knife is not just appearance, it is first about performance, and that starts with an extremely finely-made advanced technology blade. While the other parts of the knife are just as important, this page deals with heat treating and processing modern, high alloy tool and stainless steels, which far surpass traditional lower carbon, lower alloy blade steels by many orders of magnitude and in many distinctive characteristics.

Welcome to what is perhaps the best page about heat treating modern high alloy custom knife blade steels you will find on the internet, and thanks for taking the time to be here.

When this page went public, some readers (other knifemakers) complained about generalizations on the page: that each statement was not indexed, bookmarked, and referenced. I didn't want to create a thesis-style research document, full of footnotes, endnotes, and references; I wanted an easier-to-read casual text.

If you are a person who doubts what you are reading here, please read every single reference below, and then enter the terms you are doubting into any good search engine (Google is nice) and please do your own research. Then, apply that research to make your own knives.

While I'm not a professional technical writer, I am a professional knifemaker, and doing my best to offer reasonable, specific information on how I do what I do and why I do it. Other knifemakers may post their own research and results on their own sites, backed with their own examples based on their own research and backed with their own successes.

Dear Mr. Fisher,

I just finished reading your new article about heat treating and cryogenic process. WOW, thank you very much for sharing

such lots of information and knowledge. Reading it sure does brings back old memories of college times, as metallurgy is

one thing I studied back in college. The way you describe it amazes me; you do it as like you are a lecturer. Very clear

explanation, so easy to understand.

Thank you for sharing, and keep up the good work.

--Hendrik Rinaldi

"Over 80% of all metals in use are iron and steel alloys"

"Elements of Metallurgy and Engineering Alloys," ASM International, 2008

There is no way to make this simple. Modern media—movies, videogames, and television shows—always tends to show armorers, bladesmiths, and knifemakers heating, forming, quenching, and using blades in highly visual and active procession, with a lot of sparks and fire, and glowing embers scattering around the blade. This may be fine for blades made in the 1800s, but the very best blades are never, ever treated this way. The reality of modern steel and its processing is much more technical. If you just want a brief overview of the process to make superior knife blades, here's a quick step guide:

And that's pretty much it! If you are not interested in the technical nature of blade making, you're done with this page.

That's not really why you're here, is it?

Due to the complexity of the process and material, there is no way—for the sake of brevity—to sum it up with the four steps above. Steel and its crystalline forms are quite complicated, and our understanding of them determines, as knifemakers, knife users, and knife owners the choices and nature of the knife that interests us.

In order to understand the properties of the particular blade, you must first know the steel alloy. There are a vast number of blade steels available in the market today; steel has reached an extremely high level of sophistication and the science will continue to grow. Understanding the nature of this very special material will offer a greater insight into how, why, and where these steels function as they do, and why premium steels are at the forefront of modern technology in nearly every field, not just knifemaking.

This is why it's astounding to discover manufacturers and knifemakers who will not tell you what steel they are using for their knife blades! They offer some undocumented and arbitrarily-assigned name—without disclosing alloy content—when it's clear that the the steel type is absolutely critical to the performance of the alloy and its function, place, and value as a knife! Without demonstrating or revealing even the basic properties of the steel (much less identifying the alloy), the manufacturer or maker of the modern knife is negligent in his service to his customer, or he simply caters to a customer who doesn't care. That's not my client, not my customer, and not my patron.

Another important issue is one of authenticity. Makers and manufacturers are claiming superior blade performance when there is none, and that somehow, a claiming a knife blade made of modern high alloy steel is somehow inferior to the plain carbon steel blade, which is an outright, easily verifiable lie. I do not want to be part of a profession that allows lies to stand for the sake of egos, tradition, or profit, and the best way to eliminate them is with knowledge and scientific facts.

This page is for you—the knife enthusiast, the blade aficionado, and the client, collector, patron, or user who wishes to know why steel is what it is, and how an individual knifemaker can create a superior blade. This page will also make it clear why factory and manufactured knives often cut corners to increase their profit while offering a lower-performance knife overall. There is nothing wrong with cheaper, lower-performance knives, and here you will learn why they are inferior, and what the cheaper knife sacrifices in condition, and thus, function.

Knifemakers will also find this page a useful resource, I'm certain. This page will clarify why modern high alloy tool steels are so special and important to our trade and civilization. It will also clearly show why simple, low alloy carbon steels and hand-forging are crafts based in the romance and antiquated tradition, and high alloy scientifically-processed steel knife blades are the present and future superior performers and premium value.

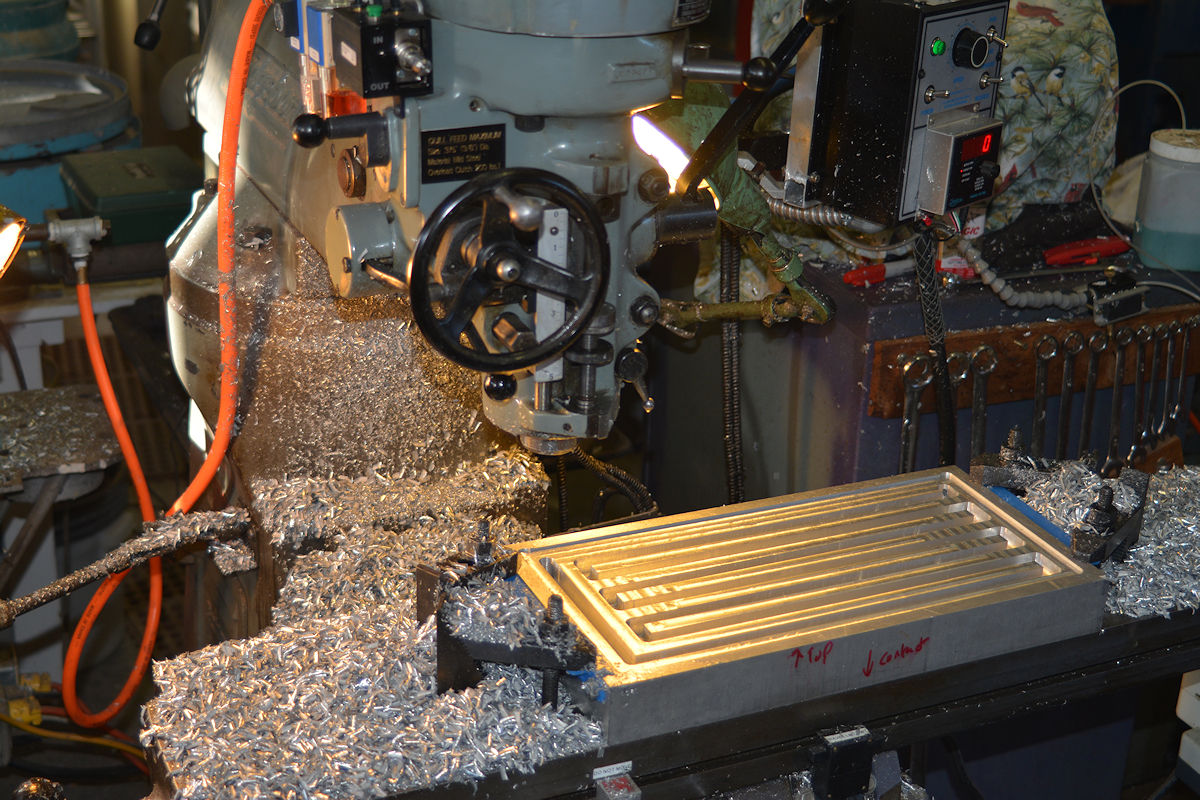

I'm not here to discard hand-forging, which typically involves lower alloy steels by necessity. If you like a hand-forged or primitive knife, that's a personal preference and I know of thousands of knifemakers who can make this kind of knife for you. The hand-forged knife blade is not the kind of knife I make, for a reason—I've grown beyond 18th-century practices (along with the rest of all modern machinists) for most of my work. I use extremely high alloy hypereutectoid tool steels, and they cannot be hand-forged; they must be treated in specifically controlled processes more like a laboratory than a forge. These are the finest, most state-of-the-art, most advanced tool steels made, and these are the steels I make my knife blades with. More so, these are the steels my clients request, and they are who I make knives for.

This is not a required page for my profession and career—gratefully, I've been successful for decades without having this page on my site. This page is a significant reference and insight into the world of creating effective, superior, and valuable knife blades with some of the finest high alloy steels on our planet. I want to honor you who are reading this with as much viable information as is reasonable, since your time is so very valuable.

The reason I've created this page is because it's my service to the my field, trade, art, and a service to the people who have made it possible for me to do what I do in my career. Improving the performance properties of the highly specialized tool steel blades is critical, and after you finish reading this page, I guarantee you'll know more than most knife owners, most knife manufacturers, and most other knifemakers about this fascinating process.

Thanks for being here!

For complete transparency, please note that since my first knife made in the 1970s, until the present day, I've heat treated every single one to the best of my knowledge and ability. Know, also, that I've never had one failure, not one return, not one complaint about the hardness and wear resistance of a single knife blade I've made.

Heat treating is not mystical wisdom, not a mystery of scientific knowledge, and not an unobtainable goal: it is simply a process. It's hot, it's cold, it's timing, it's workflow. It's numbers, it's temperatures, it's logical, like any process. And like any process, understanding, control, record, and repeatability are the keys for reliable results.

Hi Jay,

Just had to say thanks a ton for all the great info on heat treating and cryogenic treating of knives.

I'm a novice to knives but an analyst by trade, so I appreciate that level of detail to learn more about

the process. The more I learn, the more I appreciate all that goes into the art and science of knifemaking.

--E. B.

Steel is a tremendously important part of our lives. It's everywhere, from the nails and screws that hold our homes together to the vehicles we drive. From the flatware we eat our meals with to the handles of our doors. Steel is part of just about every device, machine, or object that requires some level of durability, and steel is definitely part of the machine or process that allows us to make every device or object we create.

"Steel is the world's most useful and the world's most used metal."

--Robert Raymond

"Out of the Fiery Furnace;

The Impact of Metals on the History of Mankind"

1984

Steel is, then, a creator's dream, and everything that involves steel in any way in our lives is created, because humanity created steel. Steel does not exist in nature; it is entirely man's realm. Though metals may by chance or God's hand in nature come together in rare and random circumstances, steel—as far as we know—came about only because man was tinkering with other metals: copper and tin, and then moved on to iron. Though meteoritic iron was used throughout ancient times, it's a modification of a rock, in essence, and not a direct creation of man.

Iron trinkets were found with bronze works in ancient Egypt, and it is believed that they were accidental creations discovered when smelting copper and casting bronze, evidenced by findings in Israel in ancient copper smelters. Iron oxide (rust and the powdered rock hematite) was used as a flux, a cap to prevent oxidation of copper melt. Some ancient man skimmed off the iron he had used to protect the copper. But then, the iron formed stringy lumps and had to be discarded. Because the melting temperature of iron was so high, they could not do with iron what had been done with copper. For a true melt, the smith needed 1537°C (2800°F), so he had to settle for working the iron in a spongy mass called a "bloom" and by repeated hammering, the slag could be forced out. This is beaten iron, or wrought iron.

About 2500 years ago, an ancient metalsmith created a dagger, with a wrought meteoritic iron blade and a gold hilt (or handle). It's one of the earliest known artifacts made of man-made iron. It was found in the Hattic royal tombs at Alaca Huyuk, near Hattusa in Turkey.

Near Delhi, India, there is a 13,000 pound tower, carefully constructed of pieces of forged iron. The iron is high in phosphorous, so because of this, has formed a passive protective film of oxide on the surface that inhibits corrosion. Uncounted hands have passed by, touching, petting, and stroking the iron and it is polished and oiled by the human tide. It is the largest ancient piece of manmade iron. It was made in about 300 AD, when Constantine established his Capital at Byzantium, when Galerius convinced Diocletian to persecute the Christians, and when the Ostrogoths were subjected by the nomadic Mongols sweeping in from Asia. Manmade iron alloys are very old.

Incidentally, wrought iron is a very specific type of iron, iron with less than .08% of carbon, and it's creation is described above. Other than in conservatory or historic reproduction practice, there is no wrought iron commercially available today! Does that surprise you? It should. What we see sold as wrought iron today is simply mild steel, or low carbon steel. This is the practice of using an old, respected, and traditional name to help sell the romance of the past. What would you think of the architectural railing, table stands, and garden furniture if they sold it as "mild steel, painted black"? No, "wrought iron" sounds so much more… classic.

In the past, wrought iron was not as malleable and formable as cast and forged bronze, so it languished until the Mediterranean basin was conquered by fierce invaders from the sea, whose identity to this day remains mysterious, and the chaos collapsed the entire bronze age. Bronzes disappeared, and more and more, metalworkers turned to iron. Determined to create better iron, the Hittites of Anatolia, peoples of mysterious origin, created a material that was known in their language as "good iron." It was much more durable and superior to wrought iron, and then the Hittites themselves disappeared, prey to European tribes. They left behind the physical evidence of improved iron, and an iron culture that continued widespread.

In the second millennium BC, iron smiths worked furiously with the material and in order to do this, had to expose the iron to white-hot charcoal and carbon monoxide from the combustion. This they repeated over and over to keep the iron hot enough to forge. This exposure forced carbon into the iron, and, simply as a side effect of working with the iron, steel was born. It was harder, stronger, and tougher than iron.

Just .03% increase of carbon in the iron makes into a steel that is harder than bronze. That was the final blow for the bronze age, and the addition of carbon could be directed by exposure in the forge to just the tip of an iron shaft, turning it to case-hardened steel (c. 1200 BC). During that same time, smiths stumbled onto the amazing discovery of the effects of quenching. Maybe they were just tired of waiting for the steel to cool, and wanted to get their projects done, so they quenched it in water. Then a new property was in play.

‘As he finished speaking I handed him the bright wine. Three times I poured

and gave it to him, and three times, foolishly, he drained it. When the wine

had fuddled his wits I tried him with subtle words: “Cyclops, you asked my name,

and I will tell it: give me afterwards a guest gift as you promised. My name is

Nobody. Nobody, my father, mother, and friends call me.”

Those were my words, and this his cruel answer: “Then, my gift is this. I will

eat Nobody last of all his company, and all the others before him”.

As he spoke, he reeled and toppled over on his back, his thick neck twisted to one side,

and all-conquering sleep overpowered him. In his drunken slumber he vomited wine and

pieces of human flesh. Then I thrust the stake into the depth of the ashes to heat it,

and inspired my men with encouraging words, so none would hang back from fear. When

the olivewood stake was glowing hot, and ready to catch fire despite its greenness,

I drew it from the coals, then my men stood round me, and a god breathed courage into

us. They held the sharpened olivewood stake, and thrust it into his eye, while I threw

my weight on the end, and twisted it round and round, as a man bores the timbers of a

ship with a drill that others twirl lower down with a strap held at both ends, and so

keep the drill continuously moving. We took the red-hot stake and twisted it round and

round like that in his eye, and the blood poured out despite the heat. His lids and brows

were scorched by flame from the burning eyeball, and its roots crackled with fire.

As

a great axe or adze causes a vast hissing when the smith dips it in cool water to temper

it, strengthening the iron,

so his eye hissed against the olivewood stake. Then he

screamed, terribly, and the rock echoed. Seized by terror we shrank back, as he wrenched

the stake, wet with blood, from his eye. He flung it away in frenzy, and called to the

Cyclopes, his neighbours who lived in caves on the windy heights. They heard his cry,

and crowding in from every side they stood by the cave mouth and asked what was wrong:

“Polyphemus, what terrible pain is this that makes you call through deathless night, and

wake us? Is a mortal stealing your flocks, or trying to kill you by violence or treachery?”

Out of the cave came mighty Polyphemus’ voice: “Nobody, my friends, is trying to kill me

by violence or treachery.”

--Homer, The Odyssey, Bk IX:360-412

--8th Century BC

The only thing Homer got wrong in his comparison is that quenching is not tempering, at least not during our current times and definition, in this vast history of metals and mankind.

"Steel is not the most popular metal because it's easy to produce and plentiful. Iron is not the most plentiful element and steel is more expensive and complicated to produce. For instance, copper may be found in nearly pure form in many locations on earth. Steel is such an important material because of its tremendous flexibility in metal working and heat treating to produce a wide variety of mechanical, physical, and chemical properties."

--American Society of Metals (ASM), International

Steel, in its basic form, is iron with carbon. Carbon is the number one element in steel that affects its alloy properties. While I'll get deeper into this later, it's important to know that carbon is key. As little as a few hundredths of a percent of carbon in iron makes it steel, and the percentages top out in the standard steel types at about one percent. Remember, I'm mentioning standard steels, not high alloys, tool steels, stainless steels, or specialty steels. I'll start out simply, and we'll get to the really good stuff later!

There are many other alloy elements in modern tool steels, but just for the carbon steel discussion, these are the important and prevalent players.

These are the best steels available today: high alloy steels and stainless steels. Unlike carbon steels, most of them cannot be hand-forged and must be machined (with power tools and by hand) and processed in a clean, scientific, and highly controlled environment. The predominant additional alloy elements in these high performance steels are:

While I could go on and on in the periodic table of elements to detail each alloy, the important thing to know for at this time is steel's relationship with carbon, and how important carbon is. Carbon is the most important alloy in steel and you'll understand why as you continue to read.

This can be a lot to take in; don't bother trying to remember each specific alloy and its contribution. It's enough to know that the relationship of iron, carbon, and the alloy set is synergistic, with the performance of the whole being greater than the individual elements, in strength, hardness, wear resistance, heat resistance, corrosion resistance, and toughness, when properly processed.

Mr. Fisher.

Thank you for your wonderful and well informed site about knives.

So far I have spent quite a few hours reading fascinating info way beyond of what I was looking for.

I have masters degree from mechanical engineering. In the course of my study I have also studied some

[steel] metallurgy subjects. I work as an IT contractor for a large steelmaking corporation. I *very*

much appreciate your very sensible, balanced and pragmatic info on the topic.

I just wanted to say how much I appreciate the info and wonderful advertisements on site - the pictures of your fantastic work.

Best regards

--Stanislav

from Slovakia

Steel and iron are crystals. This doesn't mean you can hold them up in the sunrise light beams and call the forest nymphs to do your bidding with a chanting spell; it simply means that they have a regular, repeating pattern of atomic arrangement. Like quartz crystals and other mineral, rock, and gem crystals, there is a uniformity of structure based on the bonding of molecules. While there are lots and lots of molecules in, say, a knife blade, for clarity it's best to look at the smallest piece of molecular arrangement, the unit cell. Many unit cells together create a lattice.

It's important to understand that nearly all iron has carbon, but it's not considered steel until the percentage is significant enough to affect phase changes. To get an idea of the variability of iron and steel in context:

From this, you can see that iron and steel have a similar makeup, but they are vastly different materials.

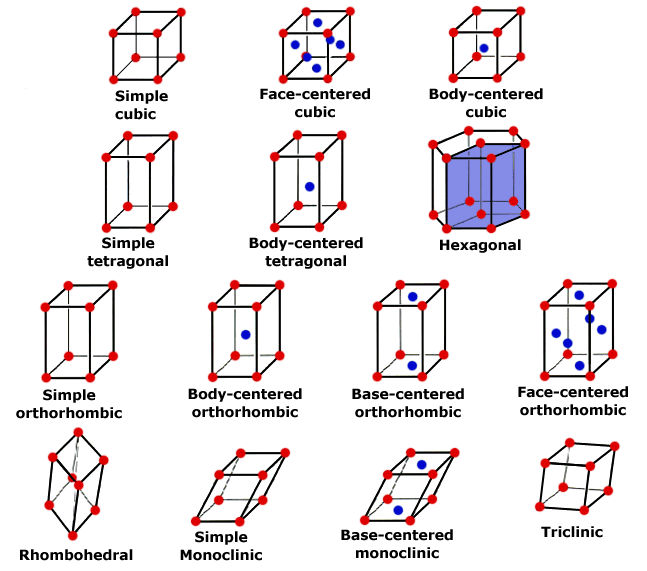

The unit cells, and thus, the lattices of metals are many, but let's start with the simplest, iron. As I mentioned before, it's important to understand that all iron contains some carbon. The carbon atom is only 1/30th the size of the iron atom. Iron only has two unit cell arrangements, face-centered cubic and body-centered cubic.

Referring to the illustration of crystal geometry above. we all know what a cube looks like; it's like a box. In the box of your mind, use a red marker to put a red dot on each corner (8 total). These red dots are atoms of iron. Now add an blue dot in the very center of each flat face (6 total). These are also iron atoms. The face-centered cubic lattice has 14 atoms of iron in this arrangement. This is a unit cell. While it's easy to see in a singular fashion, that cell shares its atoms with the adjacent cells, creating a repeating stack of cells which is the lattice.

The body-centered cubic unit cell has a different arrangement. It's still a cube, but in our box we put one red dot representing iron atoms on each corner (8 total or iron) and one blue dot representing an iron atom in the very center of the inside of the box. So the body-centered cubic unit cell has only nine atoms. Just like the face-centered cell, the unit cell shares its atoms in the corners with adjacent cells in a stack, or repeating arrangement, creating a lattice.

You can visualize these the atoms in the unit cells forming a series of stacked balls. You might consider them visually as ping pong balls, all filling a space, like a bucket. In examining these balls, you'll see that there is space between them. This is where, roughly speaking, many of the carbon atoms reside, in the center of the "holes" between the ping pong balls. Carbon atoms also exist in the interstitial spaces within the unit cells, since the carbon atom is so much smaller than the iron atom.

Those balls touch in relationship to each other, and the arrangement varies. The arrangement is the body packing of the cells, which can be an open or less dense structure of the body-centered arrangement found in alpha-iron or ferrite. The face-centered structure is more dense, and less open structure and it's found in gamma-iron or austenite. More on the phases below.

We humans are are all about heating things. We cook, we bake, we like blowing things up (heating up stuff to a point of massive instantaneous burning or oxidation). Our vehicles combust (burn) fuel, we heat our homes with natural gas (burning) or oil (burning) or electricity (produced by burning fuels). Understanding steel, though, requires a different perspective. We must think of matter and elements cooling or freezing, for that is where the real magic takes place.

When we heat up our iron to become liquid it takes a lot of heat (2790°F/ 1530°C). It looses all of its crystalline structure, just like ice looses its crystalline form when heated to liquid water; everything moves around. It's not the liquefying of the iron that's unusual; it's when it cools, or solidifies into a crystal. As it cools, the atoms lose their energy and bond with nearby atoms to form the crystal lattices. The iron first forms a body-centered unit cell structure and lattice with the the nine atoms. Remember, this is a solid, but it will transform into different crystalline structures while solid. Strangely, as the iron cools to 2550°F/1400°C, the unit cells and lattices change from body-centered to face-centered. Then, in more strangeness, at 1670°F/910°C, the face-centered lattices change again to body-centered unit cells and lattices!

It's fun to visualize this weird structural morphing taking place as the atoms bond, re-bond, move, lose energy, and transform their crystalline form and their molecular arrangement, and the iron and carbon move in form and structure. Remember, all of these crystalline changes happen while the material is solid. The temperatures at which this takes place are critical (important) for us to know, for the next considerations.

The addition of carbon to the iron changes the phases and structure as well as the time, temperature, and characteristics of how the metal reacts and exists. Carbon is introduced into the iron, and occupies the interstitial spaces between the atoms. In essence, the carbon is in a solid solution of the iron. Austenite, ferrite, and iron-carbon alloys are then "interstitial solid solutions."

Mr. Fisher,

Good Morning Sir!

I fully understand that I will not receive a response to this email, however I wanted to thank you for sharing so much expertise,

experience and professional knowledge on your website. It's truly a breath of fresh air to read some no-nonsense facts about

today's knives. The need to run to the newest "whizz-bang ultra premium vapor-deposition" steels these days are almost humorous.

I, too, am a knife maker, although not to your caliber. These days I really only focus on offering various exotic wood handles for knives, and occasion grips for pistols. I always stuck with the tried and true for steels though - 440c, O1, ATS-34 (or RWL-34), 52100, etc.

I only wanted to give you a praise, and thank you for giving a realistic approach in knife making. Keep up the good work Sir!

Most Respectfully Sent,

Kevin S.

USMC (RET.)

It is helpful to understand that when steel cools (or is heated), it undergoes a group of changes in the crystalline structure, forming allotropes of iron. Allotropy is the phenomenon that allows a singular substance to have completely different forms; carbon can be both graphite and diamond. In steels, these changes have been called various things over time, and currently, in materials science, Greek system has been adopted that incorporates some of the older terms to describe these various structures and molecular forms. We also use terms based on the name of the person who discovered or researched the phase (austenite and martensite), and we also have names based on the appearance of the phase structure when viewed through a microscope (pearlite). We even name some of the structures for their physical properties (cementite). This confusing mish-mash of terms comes from many directions, from discovery, industry, research, and applications of steel in our modern world. It's important to know what these terms are, and how they interrelate, because steel metallurgy science crosses so many disciplines.

Please understand that steel and transformations that occur are well known, but there are also some things that are not understood! Though we trust our current knowledge of steels (and other metals) we still have a lot to learn, and that's exciting! Here are the terms:

It's okay if you don't completely understand the term descriptions below; there is a lot to absorb. Steel phases and transformations can be quite detailed and complicated. Some of the descriptions are repetitive, since these phase structures all interrelate and are formed in interactions with each other.

Picturing the geometry of the crystalline structures of unit cells and how they stack, repeat, and are arranged is a textbook in itself. If you are interested in these structures, there are some great reference books identified below. Courses on metallurgy are a great educational tool, if you have the time and money.

The short version in our particular material—steel or Fe-C (iron with carbon)—is this: there are definite geometric spaces created within the structure of a unit cell of both austenite and ferrite. These spaces are identified as either octahedral or tetrahedral. This is a result of the arrangement of the iron atoms.

In these spaces, the carbon in the solution can be accommodated. These spaces are defined as interstitial voids. The voids in austenite are at a different location than in ferrite. These voids are larger than the voids in ferrite. Also, in austenite, the crystalline lattice expands somewhat to accommodate the carbon. In ferrite, the voids are much smaller. The tetrahedral interstices are also not symmetrical as in austenite, and a carbon atom there would displace the iron atoms, so the carbon tends to locate in the octahedral interstices. This means that ferrite will accommodate much less carbon than austenite.

This may seem a bit counter to logic. A unit cell structure that has 14 iron atoms has more available space for carbon in it that a unit cell structure containing 9 iron atoms. You would think that less iron atoms would allow more space for the carbon, but it is not the case because of the octahedral and tetrahedral interstices and their arrangement and locations.

An extremely simplistic way of perceiving this is with balls, often used in molecular and crystalline arrangement illustration. If you stack balls in neat, straight and axis-aligned arrangement, there are large gaps between them. Stacking them this way represents a face-centered structure, with five balls forming a side, there is a lot of room in the "cube." This represents austenite.

If you allow balls to simply locate themselves in a container, they will not stack; they will be offset between the layers, and less space will exist between them. There will be less room between them in the "cube." This represents ferrite.

I hope this simple idea helps. Please don't attack me for my generalization; I'm trying to keep it simple, and I know it's not! So, simply put, austenite accommodates more carbon atoms in solution than ferrite.

The predominate allotropes, constituents, and crystalline structures for our specific discussion of fine knife blade steels are :

Subject: Thank you for your written material

Hello Jay,

I am impressed by your material published and your will to leave behind not only

your good knives, but also your knowledge and long experience into a very narrow field.

As you do not expect, I am a Senior Design Engineer. We are manufacturing and designing quality triggers, mainly for hunting guns. Currently I am learning a lot from your written knowledge experience of using 440C stainless steel.

In some of our applications, we are using this material from solid or sintered. There are some properties discrepancies from batch to batch. We are interested in toughness, superficial hardness in a limited area and corrosion resistance. There are variations from part to part instead to have constant properties. After I will collect all data regarding our manufacturing process, in case I will not be able to find a conclusion and a way of improvement, then I will ask for your opinion.

Anyway, your material about Heat Treating and Cryogenic Processing of Knife Blade Steels: Crystal Unit Cells and Internal Interstice Geometry is very valuable for my work task.

Thank you and Best Regards,

Florin Hristu,

P. Eng.

My Response:

Hello, Florin.

Thank you for your very kind email. I’m honored that you appreciate my work.

Florin, I have seen this before, and after working with 440C for over 40 years, have been able to achieve process and methods to eliminate any irregularities. Because of the outstanding properties of this steel, it is, by far, my most requested blade steel for high corrosion-resistance, wear resistance, and toughness.

I’ll be very interested in what you discover, and if you wish, available for professional consultation.

Thank you again,

Jay

Hello Mr. Fisher,

As the title of this email already says, each time I am visiting your website (daily :) ) I become even more and more impressed.

You are for sure the best knifemaker alive and not only for your gorgeous work but also for your vast knowledge.

Any visitor, no matter of his profession will definitely find in your website a reason to go further, to learn more and to

improve reaching for perfection. I never tried to find a fault in your work as I am sure it would be a waste of time, the way you

are judging things, the sack of knowledge behind each and every thing you make is enough to know that you are facing a very fine

educated man and craftsman.

I simply adore your courage to face and combat the lies promoted by the huge "sharks" on the market, never seen this before and maybe I will never see it again; it requires arguments, self trust and motivation for the good of the customers. Once again thank you very much for all your efforts to share your vast knowledge with us! May God bless you for long and peaceful years in the Sharp Instinct Studio! :) All the best,

--A.

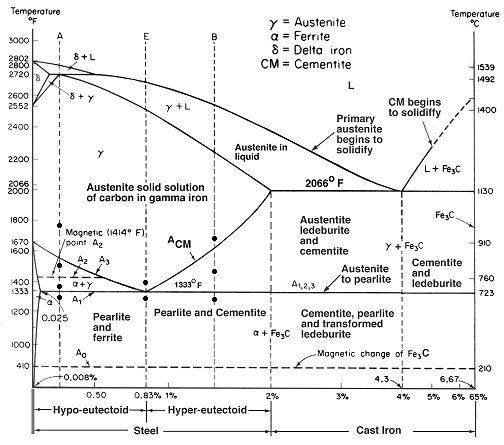

An important part of understanding steel phase transformations is the phase diagram. While scientists and metallurgists diagram many things, the phase diagram illustrates precisely under what circumstances individual phases form.

The key to understanding heat treating is understanding transformations, and our induction of these transformations. This is another reason I believe the knifemaker should do all his own heat treating, so he can precisely control the structures of his creations. This may not matter much if he's using plain carbon steels and hammering out his blades in an open air forge—rarely do bladesmiths who work this way use any method other than looking at a relative and generalized color of heated steel for their control. They look at the color of the heated steel and make a judgment. There have been attempts to substantiate this process by giving it a technical sounding name like "thermo-optical emission viewing" (whoa!), but it's dependent on the skill, references, background lighting, color sensitivity, and the material itself, and is simply a guess. This is not how the best blades made of modern high tech alloys are created; there are instruments called pyrometers that can measure temperatures to a fraction of a degree.

The knifemaker who works with the highest alloy tool and stainless steels should be part scientist, or at the least, a laboratory technician, able to produce specific, controlled, and regulated environments and exposures for accurate and repeatable results in his steels. While I do make some forged blades and use pattern-welded damascus steels from time to time, these are chosen for one reason only; the patterned appearance. The very best performers are, of course, high alloy stainless and specialized tool steels.

The diagrams that detail these specific phase and eutectoid transformations specify points at which the eutectoid transformation occurs, which are the points at which one solid transforms into two different solids with different properties and compositions, important to understanding the whole process and how critical temperature is.

While at first glance, the chart seems intimidating, for fine modern high alloy tool steel blades, we are only concerned with the narrow band of hyper-eutectoid steels. The first thing to remember is that these are equilibrium charts, and that the phases show here occur in slow temperature changes. Start at the very top of the vertical dashed line labeled "B." B is in the middle of the hyper-eutectoid band of the steel area listed on the bottom of the chart.

With this basic understanding of the phase diagram, I encourage you to look over and examine different areas and indicators on this and other diagrams. They are a rather simplistic way of showing how materials transform from liquid to solids, the eutectic points of steel and iron, and the temperatures at which all of this occurs. There are charts showing sublimation, deposition, melting, freezing, condensation, vaporization, and the crystalline structure of all kinds of materials.

Note that martensite is not on this chart, anywhere. This is the really important point here. This chart is describing material transformations at equilibrium, which for steel and iron, means very slow temperature changes. By sudden and deep cooling, we alter this slow migration of carbon and iron, and form astounding structures that drastically affect the steels performance and arrangement.

Hi Jay,

Thanks for the great site, sharing your beautiful knives, and your knife knowledge and philosophy.

I was raised as a mechanic and welder in my family’s heavy equipment business and 30 years ago, the

knowledge you are freely sharing was handed down father to son and not shared to the world.

My wife is a professional pastry chef, food blogger, and teacher. I thought she needed a custom

knife for valentines or her birthday and looking at all the $500 ‘customs’ I thought, hell I could

do better than that I have a metal shop in the garage. I started reading the knife forums and the

usual drivel about real knives being forged. Being disabled, my hammer swinging days are over.

Then I ran into your site. I spent the last week and a half studying as much as of your site as I

could digest and as importantly as how, the why's.

Thanks again for the copious knife knowledge, I help my wife on her blog so I know how involved

building and maintaining a site is. If I was blessed with riches, instead of free time and enough

knowledge and tooling to be dangerous I would put her name on your list for gorgeous Concordia,

instead she will get a well-crafted RogboBilt O1 chef and paring knife, plain but made with love.

Best,

Roger

When water freezes to ice, it happens at exactly 32°F/0°C. At this same temperature, ice turns to water. It's so accurate that thermometers are calibrated in a bath of crushed ice and water because it's exactly 32°F/0°C. This is not true with steel (iron with more carbon), and when we add more carbon, the weirdness factor increases. Steel starts freezing (solidifying) at one temperature and is completely frozen at a lower temperature. So it has a range of solidifying. In this range, steel is mushy like oatmeal or mud. Start adding more carbon, and the range of mushiness gets larger, until about 2% carbon. Add more than 2% carbon and the range of mushiness gets narrower, and then the range goes away at just over 4% carbon.

Solidification is not the only physical action where steel changes. Steel, when heated below the melting temperature to certain specific and critical temperatures, undergoes changes in the internal crystalline lattice structure. These structures are called phases. The magnificence of steel is based on these phase changes or transformations.

The word "eutectic" comes up often in steel discussion, but the word itself simply means "easily melted" in Greek. It may help to understand various applications of the word in the study of the science of materials to clarify the idea of eutectic principles in steel.

Back when I was very young and working in industry, we did a lot of welding. I worked as a maintenance electrician, mechanic, and instrumentation technician. This sounds like a lot, but mainly consisted of a small group of guys handling every single device, machine, driver, power feed, control, and regulation problem in a small-to-medium sized manufacturing plant. This meant wiring up new devices, troubleshooting failed systems, welding broken components, tuning and calibrating every machine and device the plants needed. I worked in half a dozen different plants like this: a plant that made concrete coated steel pipe, a fiberglass manufacturing plant, a secondary aluminum smelter, a pigment manufacturing plant, a circuit board plant, a radio crystal manufacturing plant, and even a large electrical generation station. Though I took vocational welding classes when I was still in high school as an advanced student, the classes were only a brief overview and introduction to real world welding issues we would encounter in the plants.

One of them, a seemingly simple one, was how to weld stainless steel to mild steel, or stainless steel to a high carbon, high alloy steel. A machine would fail, or corrode, and stainless parts were needed because, wisely, the plant maintenance manager wouldn't want to have to shut down the production line and fix the problem (due to corrosion) again. We came up with special welding rod made by Eutectic Castolin®. This is a great company that's been around quite a while, and makes some neat stuff, essential to maintenance and repair as well as welding advancements.

Now, each metal in the bond (lets say high alloy steel and stainless steel) each have a high melting point, and their melting points are different. But when you mix the two metals together in just the right percentages, you get an alloy that has a lower melting point t than both the parent metals! It's an amazing thing, and the welding rod from Eutectic Castolin® already had this perfect mixture in the rod. So when you welded with this stuff, it bonded to both parent metals at a lower temperature than they would ordinarily melt at, allowing a great penetration and bonding of the weld flow.

Simply put, eutectic transformation is a liquid cooling into a solid that has two phases.

Steels aren't the only metals to have eutectic properties. When I got into jewelry work, I quickly learned that eutectic bonding of dissimilar metals was necessary in all parts of the work. For instance, copper has a melting point of 1984°F/1085°C. And silver has melting point of 1763°F/961°C. If you try to fuse copper to silver, the silver will melt and dribble away long before the copper melts. However, if you mix up an alloy of 28% copper to 72% silver, the alloy has a melting point of 1431°F/777°C! This is great! This means that with that alloy between the pieces of silver and copper, you can solidly bond the two dissimilar metals at about 300° F below the lowest (silver) metal's melting point!

Metal alloys aren't the only materials that do this, and it's not only about melting, but also about the phase transformation of a solid. Understanding that in eutectic concentrations in steel means that several components in a specific combination create a whole that has a lower critical temperature than the individual components.

In the combination of steel, the elements iron and carbon, depending on their percentages in relation to each other and the temperature, give some steels strict eutectic points. To get gritty about this, the two atomic species form a joint super-lattice based upon their valence electrons.

To throw another term into the mix, we have eutectoid steel. Eutectoid simply means "eutectic-like," but In this case, the word eutectoid describes a process of phase transformation where one solid forms into two different solids. Steel with 0.8% (actually 0.77%, but let's round the number) carbon can transform (with heat) to austenite, and in equilibrium cooling, austenite can then undergo complete phase transformation into pearlite (cementite and ferrite) without a transition zone and without any extra ferrite or extra cementite. This is considered eutectoid steel.

Hypereutectoid high alloy steels are complex steels requiring complex treatments.

Steels with less than 0.8% carbon are called hypoeutectoid steels, and hypoeutectoid simply means a mixture of components having less of the minor component (carbon) than the eutectoid composition. Hypoeutectoid steels can transform in the same equilibrium cooling phase transformation to pearlite and ferrite. Ferrite is a soft component abundant in mild steel. Railway track is a great example of hypoeutectoid steel. So are railway spikes. You might want to consider that when you see a knife made of a railroad spike. As knives, they are ornamental only, containing carbon in the range of 0.15% to 0.30%, creating soft, weak blades at their very hardest. But some folks like the look and they are easy enough to hand-forge.

Steels with more than 0.8% carbon have so much carbon that they transform into cementite before the eutectoid point and they are called hypereutectoid. Hypereutectoid means a mixture of components having more of the minor component (carbon) of a eutectoid composition. Hypereutectoid steels can transform in equilibrium phase transformation to pearlite and cementite, with many more abundant hard particles of cementite. Cementite is created because of the high carbon content.

These steels are therefore harder, more wear resistant and more durable in long-term use as knives and cutting tools. This is because the higher carbon can form abundant carbides. These carbides are not only iron carbide, but with high alloy hypereutectoid steels, are also molybdenum carbide, chromium carbide, and vanadium carbide, and combination carbides of multi-elements. Also, high carbon creates a more profuse and abundant martensite formation, which, after tempering, creates a stronger, tougher, more wear-resistant steel overall.

The important difference in these three types of steel in knife blades (hypoeutectoid, eutectoid, and hypereutectoid) mean more than just the carbon content, though that is the defining factor. The crystal morphology is different in all three of these steels. Hypoeutectoid steels form Windmanstätten patterns in their ferrite side plates projecting into the austenite grains. The microstructure of hypoeutectoid steels will then contain Windmanstätten ferrite and fine pearlite.

Hypereutectoid steels form a continuous network of hard, brittle cementite along the prior-austenite grain boundaries, and are typically only used where extreme hardness is required, such as in cutting tools.

In all types of steels, the ultimate tensile strength increases with increasing carbon content. However, yield strength varies little with increasing carbon content.

The only advantage of using a lower-carbon hypoeutectoid steel is increased ductility, which means a softer knife blade more likely to bend than break. This is not the reason to make a fine knife blade; cutting tools cut because of high hardness and wear resistance. Hard edges cut; ductile edges bend and dull.

Most chef's knives and kitchen knives made and sold today are made of hypoeutectoid stainless steels because they are inexpensive lower alloy, lower carbon steels. Being available in sheet stock, it's easy and fast to punch-press them into knife blades. They only require simple and fast heat treatment that is usually automated, and are easier to machine, grind, and finish. They also dull much faster, requiring constant steeling, honing, and sharpening with traditional methods.

A good use for a ductile blade is a machete, since it will likely encounter rocks and high impact. But making soft, ductile machete blades is really not the realm of the maker of fine knives, because soft, ductile steel blades are a dime a dozen at any hardware store, big box warehouse, or lawn and garden outlet.

Hypoeutectoid steels have also been extensively used in structural steel applications, and were produced in extremely large tonnages. However, even the hypoeutectoid steels are being replaced in structures by High Strength, Low Alloy (HSLA) steels because of higher toughness.

Hypoeutectoid steels are limited in function, and simply make inferior knife blades. They do forge well, and that is their main attraction in this field. As I've detailed before, hand-forged blades are mediocre in every performance aspect when compared to blades that are machined, offhand, in stock removal method using hypereutectoid steels, particularly with lengthy, detailed, and high performance cryogenic heat treatments.

If you're familiar with this website, you know that all of the steels I use in knife blades are hypereutectoid. They have a lot of carbon, for good reason. You won't see this terminology used by knifemakers and knife manufacturers because they are often using hypoeutectoid (lower carbon) steels, and thus revealing this doesn't sound so great. Even in the stainless steels, hypoeutectoid types are the more common players in handmade knives. Steels like AEB-L, 13C26, and 14C28N that are commonly used for knives are low performing hypoeutectoid steels, having only 0.67% carbon.

Hypereutectoid steels are harder to heat treat, with more complex and necessary deep cryogenics for maximum transformation into martensite, and more profound development of allotropes. They are not steels that can be fudged, estimated, or generalized in their treatment, they must be handled with high accuracy and control of the process.

Just because a knifemaker uses hypereutectoid steels doesn't mean he's treating them right. Most knifemakers absolutely do not treat them to their highest potential, missing the marks on temperature (deep cryogenics required) timing (low cooling slope of time vs. temperature), and multiple temper cycles that have strict control with deep cryogenic equilibrium stages in between. Hypereutectoid high alloy steels are complex steels requiring complex treatments to bring to their pinnacle of condition.

The reality is that higher carbon hypereutectoid steels are the better steels for knife blades. They are superior because they have high carbon content. Whether or not they are stainless steels, high alloy steels, or just plain carbon steels, the amount of carbon is critical to their performance and value.

The words hypo-eutectic and hypoeutectoid, and hyper-eutectic and hypereutectoid are different and have different meanings depending on the country and language, as the United Kingdom and European English version of the word is not the same as the American English version, so research papers and presentation vary somewhat.

Hello Mr. Fisher,

I just want to thank you a lot for writing your long detailed page on heat treating.

After about 4 days of scrolling internet forums and such, your post laid it out the best.

So relieved...!

Thank so much for your time... otherwise all the best!!

Sincerely,

Marc Stanton

Thank you again- like finding the holy grail of treating that cut through all the floating opinionated stuff.

"Martensite is the most important constituent produced by heat treatments designed to produce ideal mechanical properties."

--George Vander Voort

Martensite and the Control of Retained Austenite

Metallography, Failure Analysis, Archeometallurgy Consultant

Martensite is probably the most important crystalline structure knifemakers and toolmakers are concerned about, so I want to go into it a bit more. Martensite is formed from austenite (gamma-ferrite) detailed above. When heated to transformation temperature (the decalescence point described below), the ferrite (alpha-iron) and cementite (iron carbide) transforms to austenite (gamma-ferrite). The body-centered cubic lattice structure of ferrite transforms to a face-centered cubic lattice structure, containing up to 2% carbon in solution. The carbon has migrated from the orthorhombic cementite structure into solution, and also into the face-centered austenite. Since carbon atoms are 1/30th the size of iron, there are extra carbon atoms in the lattice structure floating around in the interstitial spaces (the spaces in between the iron atoms in the lattice).

In slow cooling, the carbon atoms will drift back into the alpha-ferrite arrangement (body-centered) alternating with layers of cementite and stabilize. In high carbon steels this slow cooling produces pearlite, layers of ferrite with cementite as the carbon diffuses into coalescing cementite layers (recalescence explained below). The cementite is in platelets.

This is an equilibrium phase, where physical changes happen at fixed temperatures with the material at thermodynamic equilibrium, without consideration for time. In simpler terms, equilibrium means staying at the same temperature for a long time, or extremely slow changes in temperature. These phase changes happen in equilibrium by diffusion, where atoms move due to thermodynamic and internal motion. The carbon moving within the face-centered and body-centered interstitial locations is a product of diffusion. These phases are represented on an equilibrium phase diagram, but martensite is not.

The reason martensite is not represented is because these particular phase diagrams are for materials at equilibrium. Martensite is not an equilibrium structure because it grows without diffusion, from it's parent austenite, inheriting its chemical composition. It does this by displacive transformation. It's also highly strained, a kinetic product brought about as a result of rapid thermodynamic temperature changes, again, not at equilibrium.

In fast cooling, the carbon simply has no time to move very far, so it's forced into the crystalline lattices making a new arrangement called martensite. Martensite is actually a distortion of the body-centered structure, making the lattice into a strained tetragon (rectangle). The actual movement of atoms within the crystalline lattice structure is no more than the distance between two atoms. The crystal structure has lots of dislocations, which can be envisioned by plenty of forced angles from many directions, strengthening the steel.

So the crystals are—in simple terms—interfering with others, strained, twinned, and bent. I know, you metallurgists are wincing, but I'd rather not go into the details of edge dislocations and screw dislocations formed by shear and wave front motion in evolving crystalline bodies. It's enough to know that many dislocations create an irregular lattice, which is much harder to break.

The microstructure of martensite has no simple analogy that is easy to understand in our physical world. The science of steel is rather complicated, so, without getting into morphological and crystallographic characteristics, the strength of martensite (over the same steel untransformed) is caused by: dislocations, fine twinning of the crystalline bodies, smaller grain size, and movement and segregation of the carbon atoms. Additional strength is caused by the formation of carbides. More on carbides later.

Martensite doesn't form all at once on cooling. It has a start temperature (Ms) and a finish temperature (Mf). In this cooling range, austenite transforms to martensite. The cooling has to occur quickly, otherwise, the crystalline structure will convert to bainite, or if cooled even slower, pearlite, the layered alpha-ferrite with cementite. Slower cooling also allows the austenite to stay austenite, or be retained as austenite. While there is always some austenite retained and some converted to martensite, the amount is very important. In the scientific sense, there is no absolute martensite finish temperature; this is determined at 95% transformation, since complete transformation is not known. So, Mf =95% martensite transformation. The important procedure is transforming as much austenite as possible into martensite.

But what about all that extra carbon? In martensitic transformation, it's forced into small, chunky particles rather than the layers and platelets of cementite as in pearlite. These tiny, extremely hard particles become carbides in further treatment steps, and are spread throughout the martensite, and increase the wear resistance tremendously.

Simply put, martensite is similar to the body-centered cube ferrite (bcc), but instead of a cube, it's body-centered tetragon (bct) with more carbon occupying the spaces between the iron atoms. The transformation reaction is very fast, at near the speed of sound. Since the bct structure is less densely packed than the fcc structure of austenite, there is a volumetric expansion, resulting in hardening of the steel.

Did you know that:

"Martensitic transformation occurs in other metals and materials, not only in steel.

It occurs in, for example, nonferrous alloys, pure metals, ceramics, minerals, inorganic compounds, solidified

gases and polymer."

-H. K. D. H. Bhadeshia

Martensite in Steels

Materials Science & Metallurgy, 2002

Hello Jay,

I am just delving into knife making as a hobby. Your website is a treasure trove of valuable information that

has been a great reference for me. Thank you for investing the time to share your expertise.

Regards,

Charlie Ward Wright IV

These are curious properties of steel allotropes, and can help in understanding how carbon migration, phase changes, coalescence, and the whole heat treating process works with steels. Decalescence and recalescence are physical properties based on temperature, and may be used to describe or indicate the critical temperatures where these phasic changes take place. However, they are not something manipulated or changed in any way by the knifemaker, simply something that occurs. Not understanding these reactions may lead to improper, ineffective, or less than optimum heat treating.

As the alloy is exposed to heat, the actual temperature of the steel continues to increase. At critical temperatures, phase change starts to take place. At these points, the steel temperature does not increase, even while additional thermal energy is being supplied by the furnace. Instead, the temperature of the steel decreases as the energy is used to transform one phase of the steel to another phase. Applying additional heat will not increase the temperature of the steel, only encourage further transformation. When transformation is complete, the additional heat supplied by the furnace will then cause the steel to increase in temperature in a more normal fashion. What's important here is that the energy is being used to change the crystalline lattice structure of the steel. This property of absorbing heat energy while decreasing in temperature during heating as phasic change is underway is called decalescence.

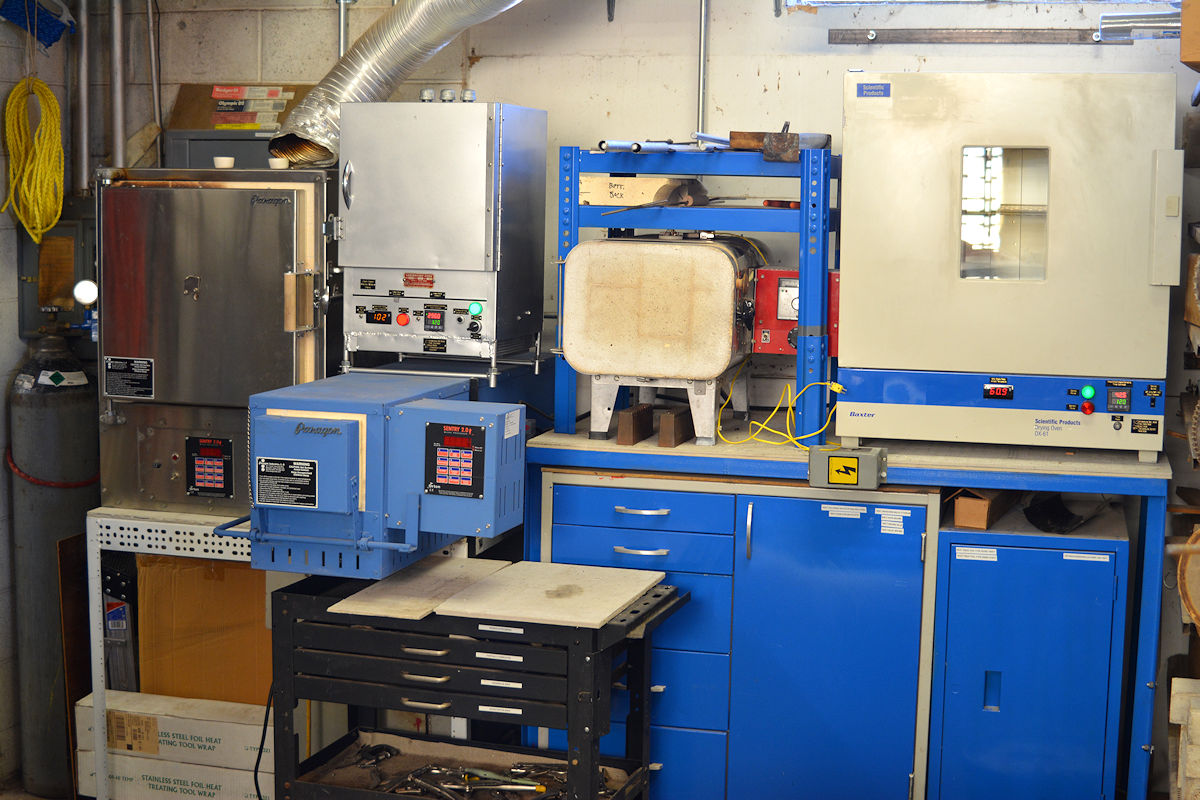

In decalescence, the important thing to remember is that plenty of ambient heat and ample time in the furnace is necessary for the phase change to take place, and temperatures must be closely held and applied. This is why the best heat treatment takes place in an electric furnace with accurate pyrometers, regularly checked and calibrated. Too low of a critical temperature, or too short of an exposure to that temperature, and complete phasic conversion will not take place. The blades need to be removed immediately after full phasic transformation, and not heated further. This is another reason that hardening is not accurate in a blacksmith/open forge environment. In that environment, judging the time and temperature for decalescence is only an estimation. This is why no industrial, machine shop, or heat treating facility uses open forges (or blacksmiths) for this critical step.

A critical point is that the decalescence point should not be held too short, nor too long, and the cross-sectional geometry of the blade being heat treated plays a large role in this. A thin blade must not be held too long above this temperature, a thicker blade must not be held too short. This varies from blade to blade, and the only way to control this is for the knifemaker to have an understanding and complete control of the process with accurate equipment and devices in use.

If the steel knife blade is heated for too long or for too high of a temperature after the decalescence point, the carbon will start to migrate to the surface of the steel and bond with any free oxygen, decarburizing the steel. This is a serious fault in heat treating, and it mainly comes from overheating the steel for too long or for too high of a temperature, or exposing the steel to an oxygen-rich environment during heat treating. In the machinist's guide and in other heat treating references, decarburization is listed as the number one failure in heat treating steel!

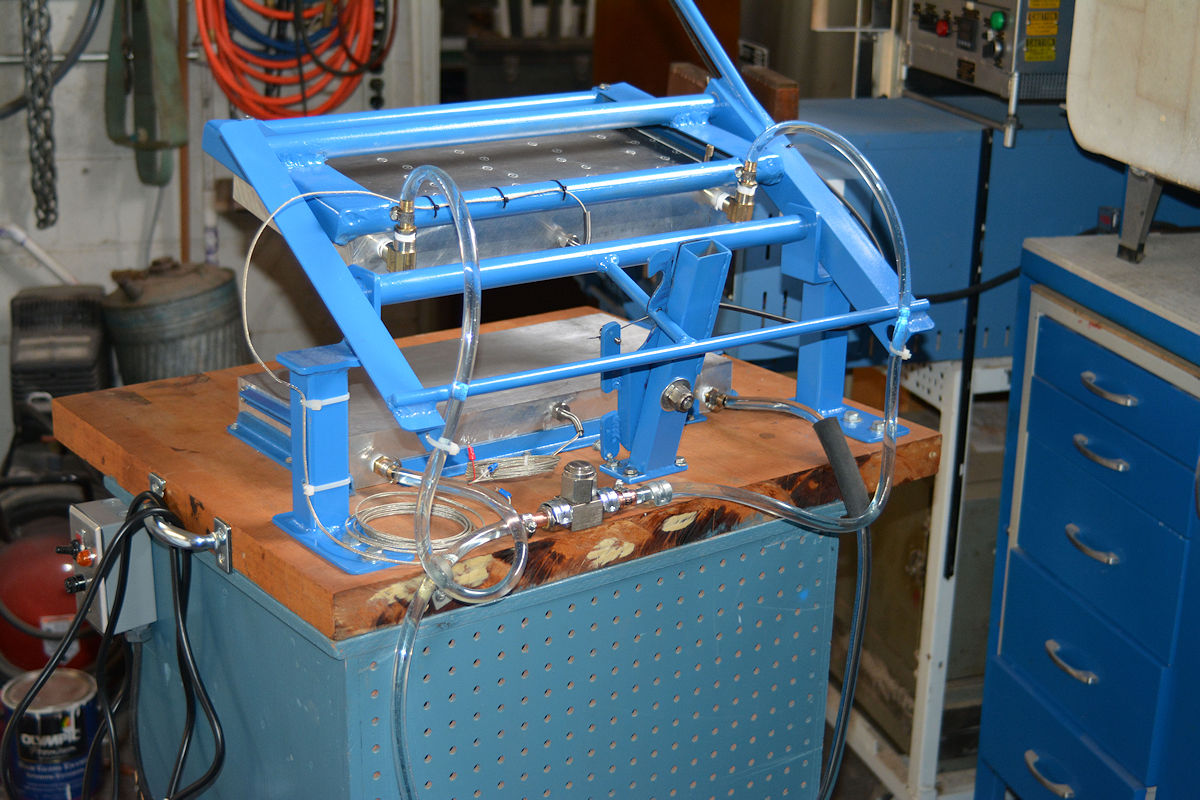

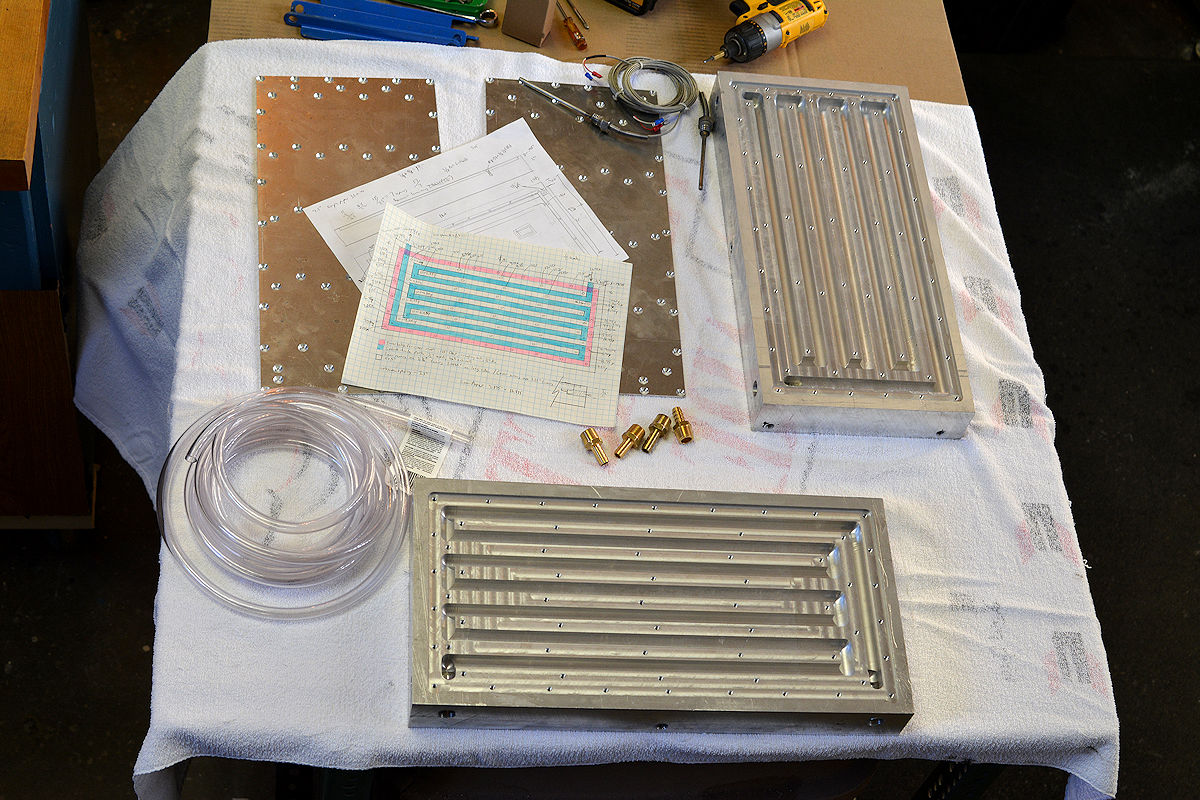

In my own studio, I've used protective environments for decades, including vacuum, inert gas (nitrogen and argon) purged furnaces, and stainless steel foil wraps that create an oxygen-depleted environment around the blades. In all of these types of decarb protection, certain other steps are necessary to ensure the proper and immediate transformations take place, such as adjusted timing, quench methods, post-purged environments, and manipulations of the environment furnace and quenching equipment. It's critical in all steels that will be used as tools to prevent decarburization during heat treating. Yet, in open forges by blacksmithing methods, decarburization is expected as if it's normal!

This is important, because If a blade is decarburized, two things happen. The first is that a black, hard carbon-rich crust will form on the blade, and will have to be removed. This "scale" is composed of a significant portion of the carbon that has migrated out of the steel to the surface and bonded with free oxides in the atmosphere. Grinding, sanding, and removal of this crusty surface of the steel means extra effort, changed geometry, and difficult finishing.

This indicates the second and most severe failure of process in decarburization. The carbon content of the steel is lowered, meaning less martensite, less carbides, and a softer, less wear-resistant, and weaker blade overall. It is a very bad thing; truly a failure of heat treating. You might read that blacksmiths and unprotected furnace heat treatment creates a scale that has to be ground away to "get to" the steel underneath that is not decarburized, but the depth of the decarburized steel can only be estimated, and is uncertain and tenuous. This is why no professional heat treating organization uses an open-air or unprotected method.

Think of this. There is one critical place on a knife blade where decreased carbon in the steel would do the most damage. That place is the cutting edge. Since it's the thinnest place on a knife blade, it has the greatest propensity to decarburize. There isn't much steel there, and the carbon can deplete from both sides, dramatically decreasing the carbon in the alloy... right at the cutting edge.

There is no way for decarburization to be seen in a finished knife blade, no way to correct it if it does happen. The result is a blade that performs less than expected, has less carbon available to create carbides, and has lower wear resistance overall. This is because loosing carbon converts the steel to a lower carbon alloy! More about decarburization below.

This is the temperature slightly above the decalescence temperature that the steel is brought to in order to ensure that complete transformation has occurred. There are all sorts of interpretations of this temperature, some saying 50°F, some saying 100°F above the decalescence point, but it is truly only confirmed by experience guided by the manufacturer's white papers. Even the white papers may give several different hardening temperatures with the different results produced. Here, the experience of the knifemaker is key, along with accurate electric furnaces and calibrated pyrometers.

Recalescence is similar, only an opposite in physical reaction of decalescence. As the steel is cooled at critical points, phase change gets underway and even though the ambient temperature is dropping, the steel increases in temperature at these critical points. This is because a phasic change is happening. This is the steel trying to reach entropy, and it has to give up some latent energy while undergoing physical change to do this. So it heats up while cooling during phasic change as this change of state releases energy.

With recalescence, the same concerns exist as in decalescence, but with some more dramatic applications. Effective cooling will absorb latent heat during recalescence and phasic change, and enough coldness (absorptive environment) will allow the extra latent heat to be pulled from the steel, effectively aiding in phasic change. This is important in annealing.

However, in knife blades, during normal heat treatment, we do not want recalescence to occur! Recalescence is an equilibrium reaction, in other words, it happens in slow transformation, with austenite transforming to pearlite and ferrite. Unless we are fully annealing a blade, we don't want this to happen; we want martensite instead. In order for this transformation to occur, we need fast and immediate cooling so recalescence can not happen. This means an even more robust cooling environment with the ability to pull the heat from the steel at the most rapid rate possible without resulting in stress fractures or warping.

Because of these critical temperature reactions, it should become clearer that the most effective means to control this environment is an electric furnace and accurate freezers with calibrated and accurate pyrometers. To try to do this visually at the blacksmith's forge is simply a guess, which may be only a fair estimation in hand-forged hypoeutectoid blades. This method should never, ever be used in the treatment of hypereutectoid high alloy and stainless tool steels.

Titled: Knife Heat Treating Article

"Nice article. A college course in itself.

I have learned more about knives from your web site than anywhere else.

Those TV shows like 'Forged in Fire' are somewhat amusing now."

--R. S.

You'll undoubtedly read or hear about retained austenite (RA) in knife steel and tool steel discussions. No matter how a piece of hypereutectoid steel is treated, there will always be some austenite retained in the structure when it finally reaches room temperature. Everybody wants to limit or decrease the retained austenite because it's softer than the martensite or carbides in the structure, and decreases the steel's hardness after heat treatment. Retained austenite reduces the mechanical properties of the steel significantly, negatively influencing yield strength, machinability, fatigue strength, and even corrosion resistance. It even affects the size of the steel!

On the other side of the argument, some austenite is necessary for resilience of the structure and during tempering, the austenite is transformed to ferrite and cementite, toughening the structure overall. However, that is tempered austenite, not untempered austenite, and there is a huge difference.

Martensite expands when it forms, and any remaining austenite is surrounded and pressurized in small islands, with force exerted by the martensite expansion. In order for the austenite to transform to martensite, it needs to expand, but it's trapped. When the steel is brought into service, pressures and elastic deformation can allow retained austenite to transform to martensite, but the steel has already been tempered, so these tiny islands of untempered martensite are brittle and can cause fractures. Since it is on a microscopic scale, this would present in a knife blade as high wear at the cutting edge, exactly what you don't want in a knife blade.

Overall, knifemakers and tool makers want to reduce the amount of retained austenite, and increase the amount of martensite, giving a more durable structure that can then be tempered to the preferred balance of hardness and toughness that the blade and knifemaker, and ultimately the knife user requires.

Just what is that balance? It depends on the steel type, the intended use of the knife, the habits and application of the knife user, and the skills and understanding of process by the knifemaker. This is another reason a maker should, at the very least, heat treat his own knives. Sending a knife off to a heat treater who slaps a "58HRC" on the blade is a cheap and fast solution, but not participation of, understanding of, and result-based function of the knifemaker. It is not custom, it is not controlled by the maker, it does not demonstrate to the knife client that the maker has a grasp on the complexity of the process. If he doesn't have a grasp on the basic metallurgy of the blade, what does that say about the geometry of the blade, the fittings and fixtures, the handle? What does that say about his understanding of the knife use and application, durability, and longevity? What does that say about his practice creating the sheath, stand, or display? These are all parts of knifemaking, and they start with the blade.

Consider that chef's knives can vary in temper depending on the style, use, and preference. A boning knife may be favored by the chef to be from 55HRC (springy and flexible) to 62HRC (extremely hard, rigid, and wear-resistant). I've had clients requesting one of each! Knives used in combat and counterterrorism may range from shock resistant and tough to ultra hard, bordering on brittle, and every point in-between. This can depend not only on the user preference, but the blade and knife design and construction overall, including the features of serrations, armor-piercing thickened sections, or razor-thin recurve areas. It is a very delicate balance and it's only learned by experience and feedback, coming from years of custom knifemaking. So it's easy to see how a heat treating contractor farming dozens (or hundreds) of blades through his line at once cannot offer much in the way of variety or specific treatment.

How does one determine the percentage of retained austenite? X-ray diffraction, that's how (by ASTM and SAE standards). Since knifemakers are not typically in possession of this equipment, they must be educated on the standard practices and procedures to produce the desired levels of these structures in their shops and profession. The information is out there, available to everyone, and there is no reason anyone who makes knives and has a access to the internet should not have a grasp of this. Granted, most knife users are not interested in the amount of retained austenite in their knife blade, but they do want to trust their knifemaker or knife manufacturer to supply them with the best knife possible in their budget.

Simply put, we want to limit retained austenite to as small a percentage as reasonable, with as much of the austenite transforming into martensite as possible. It's pretty simple to perceive, but extremely interesting to understand how it all happens.

Your Web Site-

Dear Sir,

I am impressed; you are the epitome of a professional.

--Alan

The word quench comes from Middle English quenchen, from Anglo-Saxon cwencan, causative to acwincan: to decrease or disappear. The definition currently is to destroy, extinguish, or in our field, to cool suddenly, as in heated steel, by immersion in water, oil, or air. Rather than look at quenching as an act of extinguishment or decrease of the heat, we must take a different view; one of transformation in the suddenness of time. In my view, it's not the heating that is the amazing thing, it's the quenching, and the results of the nature, timing, medium, rate, and depth of the quench.

Quenching, like most aspects of this profession, is a balance. It's a balance of cooling the blade steel as rapidly as possible, but not so rapid that the shock of cooling causes cracking and fracture. Want to know what I mean? Take a piece of 440C high chromium stainless steel and heat it to 1900 F. Pull it out of the furnace and quench it in cold water. It screams, it cries, it shudders, it vibrates as if the hounds of hell are tearing at its soul. And then it shatters into dozens of pieces that settle to the bottom of the bucket. Okay, just a visual for you to consider, but fun, anyway.

The balance a knifemaker walks is one of sudden and deep enough cooling to transform austenite into martensite, but not so sudden as to so severely stress the blade that it cracks. The exact quenching method is specified by the steel manufacturer or foundry, so it's not some mystical question that has to be resolved. Many steels (like O1 oil hardening tool steel) are designated by their quenching medium (as are A2 for air hardening and W2 for water hardening). The designation is not consistent and sometimes a particular steel type can be quenched in several different mediums. For example, ATS-34 may be quenched by air or heated oil, with slightly different results. This is another reason for knifemakers to heat treat their own blades, as entirely different properties are derived depending on these steps.

You may note that the medium designation is followed by the word hardening. This is what quenching does, it hardens the steel. It does this mainly by suddenly transforming austenite to martensite, taking a blade from a soft, plastic, glowing hot mass of steel to a cold, hard, stiff, and brittle one.

There are three considerations in quenching, and together, they play a pivotal role in the character and structure of the steel knife blade. They are:

While the white paper specifies the recommended treatment and expected results, there are some issues with these documents and their presentation. More on that below. Generally, though, they are a reliable guide to processing individual steels.

For centuries the Swiss would take advantage of the extremely low temperatures of the Alps to improve the behavior of their steels. They would allow the steel to remain in the frigid regions of the Alps for long periods of time to improve its quality. Essentially, this was a crude aging process accelerated by the very low temperatures. What we now understand to have happened was the reduction of the retained austenite and the increase in martensite. By performing this once secret process the Swiss obtained the reputation for producing a superior grade of steel.

Lakhwinder Pal Singh, Jagtar Singh

"Effects of Cryogenic Treatment on High-speed Steel Tools"