Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Cassiopeia"

--SZ (Super) USAF Pararescue

This page is arranged by bookmarked topics, all available through the topics box at the top of the page. You'll see a good assortment of thumbnail knife photos of knives that I've made for United States Air Force Pararescuemen, SERE professionals, and even a group at the bottom of the page that are Pararescue designs, but made for other individuals, units, and specialties. The thumbnail knife photos are described in the alternate text (available in most browsers when the cursor is hovered over the thumbnail), and the photos themselves are annotated. If an individual page exists for the particular knife with additional photos, information, description, and text, the link is included at the name below the thumbnail.

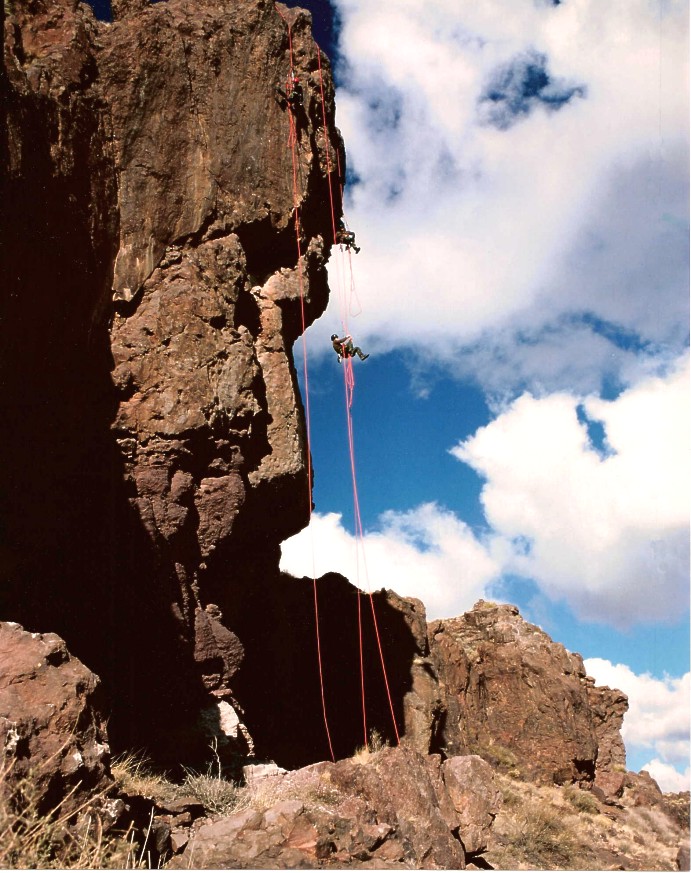

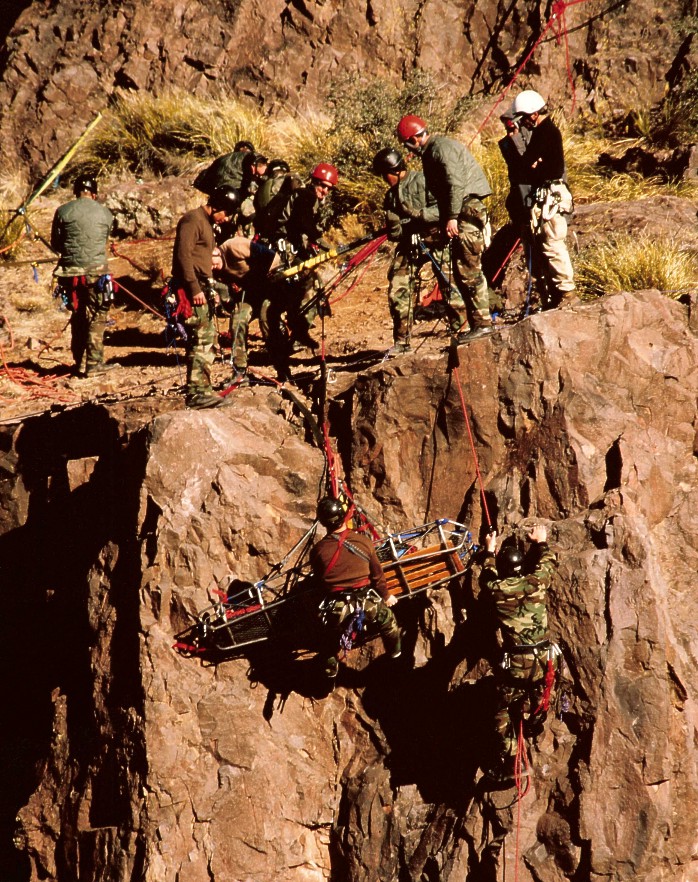

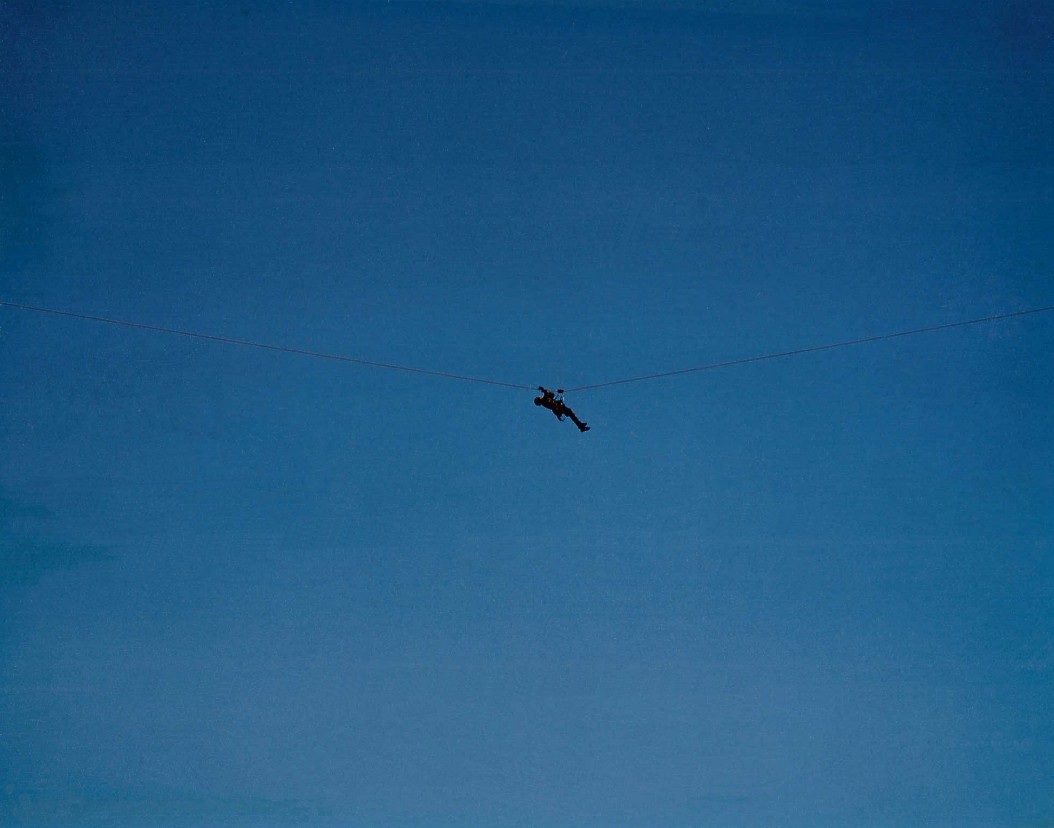

You will also see my photographs of United States Air Force Pararescuemen and SERE Specialists in training. I've included with them the description and details about what you see in the photo.

There is no right way or wrong way to cruise through this page (or my site!) If you are interested in a specific topic, you can jump there, but I suggest taking the time to scroll and browse down the page at a leisurely pace, so you don't miss a picture or a word.

If you are a PJ and want a professional grade Combat Search and Rescue Knife, you are in the right place, the only place in the world to get the best knife made for CSAR and specifically for PJs. Email me with your interest, and I'll get the ball rolling to get you equipped properly.

If you are not a PJ, please know that you can benefit from the input of Pararescue in the CSAR knife world and experience, as these designs are available in custom knife projects, no matter your service, interest, or country. Contact me with your knife project idea.

I will continue to update this page, topics, photographs, and links, so please continue to visit for the newest knives, details, and designs. Thanks for being here, and please take the time to thank a serviceman for his duty, and his family for their sacrifice.

"Jay Fisher is the best modern knife maker around, pursuing an ancient tradition but beautifully perfecting the craft by selecting the finest man-made and natural materials. Jay makes every type of edged steel weapon, fitting the blade to it’s purpose. The world’s elite clandestine rescue and tactical squads seek his weapons. Their lives depend on Jay Fisher Custom Knives- the best quality knives in the world."

--Bernardo M. Perez

Deputy Assistant Director-Ret.

FBI Laboratory

Washington, D.C.

For many years, I've been honored to know and have a professional affiliation with members of the United States Air Force Pararescue, our nation's top military rescue service. These PJs (Pararescue Jumpers) are amazing men: starting with the toughest training in the military, ending up in every aircraft military rescue operation, over land or sea, and in countless civilian rescues beyond the scope of typical or civilian rescue personnel. They are incredible soldier-paramedics, trained in advanced combat lifesaving techniques, water rescue, survival, combat tactics, mountain rescue, navigation, and many other fields. They parachute behind enemy lines to rescue our own and our allies, in the worst conditions of battle and environment imaginable. When the situation completely goes to hell, these are the guys that will put their life on the line to come in and take you to safety.

This page is about the knives I make for United States Air Force Pararescuemen, with plenty of examples and links to these very special knives right here on my web site. I've included sections on the history, a bit of anatomy of CSAR knives, other associations I've had with PJs, and where the future of this is going. Thanks for being here, and please thank our servicemen for their sacrifice!

Many years ago, while working one morning in my studio and shop in Magdalena, New Mexico, a group of tough looking men in BDUs rang the doorbell of my shop. They had seen the sign on the store front and talked to several people in town who told them that I make knives, pretty good knives at that. They told me they were interested in some well-made Combat Search and Rescue (CSAR) knives, knives that would meet their specific needs and requirements, built with the toughest, most durable and corrosion resistant materials possible, knives not meant for show, but designed and built for real work in the field of professional rescues, both civilian and military, peacetime and combat.

I had built many tactical combat knives before that time, knives for Special Forces, knives for Army soldiers, Marines, and law enforcement. I had built EOD knives, knives for hazardous material exposure and containment, and knives for specialized rescues. I had also build plenty of commemorative knives to honor the pros that use them. Combat Search and Rescue was a new field for me then, and the PJs wanted direct input into the designs. They told me what they needed, I told them what I thought would and wouldn't work, and why. We started profiling in acrylic, forming, tuning a handful of designs, and I continued with building some prototypes. I adjusted these designs over time, they frequently had new plans and ideas, and I incorporated those concepts into new models. They took the knives, used them in the field, and gave me feedback that would help improve the performance, carry, and use of these critical tools and weapons.

Today, I still make Pararescue knives, still continue to take ideas and design improvements, and still communicate with both active duty PJs, retired PJs, and PJ hopefuls that are still in the pipeline. Their generous advice and input has helped me grow as a knife maker, artist, and weapon and CSAR tool professional, and I am proud that my knives have helped them in their critical and dangerous missions.

The knives I make and have made over the decades for Pararescue are wide ranging in their design, scope, and performance requirements. Each PJ has his own ideas of what he needs the knife to be able to do in the field of conflict, and since every man is different, and units allow each PJ to carry his own knife, there are a large variety of designs available. Many years ago, units quit issuing knives service wide, as few were happy with the the knives manufactured and issued for combat. I'll go into this more deeply in my book, but just remember that knives are a very personalized up close item. For example, a firearm is clearly a mechanism, and mechanisms must be standardized so that they can be repaired, components interchanged, calibers standardized, and actions all tightly confined in specifications and construction for reliability and mass use across many fields of engagement. A knife is clearly not a mechanism, it is a form, although some of my combat knives have mechanisms, these are usually in the sheath retention systems. As a form and not a mechanism, there is no possibility of a knife itself failing. It is either present or not. Thus, the dependability of the knife and its particular place in the mission is entirely dependant on the user. Because there are mechanisms in the sheath retention system, it is of a high order of importance that the mechanism be extremely well built and durable. I detail this in the accessory section below.

Here is a list of bulleted points that detail how my Pararescue knives are designed and built. If you thought that all CSAR knives are alike, read on, brother, these are important points to know to be the best equipped for your missions.

The most important consideration for the Pararescue knife is the mission. There is no way that a knife maker could know the details and intricacies of mission details, no matter how well connected and knowledgeable he is about Pararescue. As a knife maker, however, I am well versed in knives in general, and my knives in particular. So when a PJ requests a specific style, attribute, or feature on a fine, handmade custom knife for CSAR, I can advise him on whether or not the feature will work, how it may compromise other components, fittings, or attributes on the knife, and if it is within the scope of his project based on the materials, design, size, accoutrements, and budget.

Each PJ is different, though you may see many repeats of the same knife design and style here on the site. This is because those particular knives cover a wide variety of mission requirements, along with suiting a large cross section of knife users. For example, my PJLT is my most popular CSAR knife that has found favor in many fields apart from Pararescue, in law enforcement, emergency response, and utility carry. There is no single knife style or design that can do it all, and most people know this, so choices of knife design, style and materials should be based on the idea of mission use or application. Simply put, what will the knife need to do and how will you get it there?

Some primary considerations:

1. You might have noticed that I started with what is usually the last consideration, the sheath. A knife in combat is not carried, it is worn. A nail file, a multi-tool, a tiny pliers is carried, usually in a pocket or pouch. This is not a CSAR knife. By the very nature of its use, The CSAR knife is large, and as an independent tool, it must be worn on the body. It can be worn on the belt, but in combat, more often than not, it is worn on a tactical carry system such as PALS webbing on ILBE or MOLLE systems. Since the knife is worn, not carried, the wear system is paramount to its function in mission.

2. The knife must be extracted from the sheath. For the common knife user, it's a grab and pull operation, sometimes with the additional requirement of unsnapping a flap or strap. This is not enough to consider. The PJ may have gloves on, will undoubtedly have other gear mounted, and a CSAR knife must be accessible in a variety of physical body positions, easily available when an emergency happens. If your foot gets wrapped in a moving cargo line or webbing, and you need to sever a trap in a hurry, you'll need to get that razor sharp piece of steel into your hand quickly. If you've got a knife mounted to your leg, or at your back, you'll instantly regret that choice of location and it may cost you and your charge dearly.

3. The knife is not a fixed object, and can be held in a bewildering variety of grip styles. The professional should know whether his knife will be mostly held in forward or reverse grip, with edge out or edge in, or if he will need to neck up on the grip for fine cutting. If the knife has serrations (most CSAR knives do), will the handle shape and design support the forces applied for sawing through those tough materials? The choice of handle should be in response to how the knife will need to be held.

4. Only after the previous considerations should the CSAR professional examine the actual knife use. You might wonder why I'm insistent on this ordered list. It's because if you can't get the knife to the action, easily and reliably extract it and grip it, it won't matter what it's used for. If a knife does not suit these three previous points, you'll end up leaving the knife in your locker at base because it's just not practical. I get emails from guys all the time that think they have a decent knife, but can't wear it, depend on the sheath, mount it accessibly, and hold it reliably to actually use it in rescues. They do know what they will use the knife for: for extraction, cutting, sawing, slicing, light prying, rescue, or defense. I depend on the PJ or rescue professional to know these things, and consider the knife accordingly. If a knife's primary use will be deep slicing, a knife with a curved belly would apply (like the Paraeagle), if a stronger point is required, with a stronger tip, the tanto-bladed PJLT is a good bet. If a super heavy duty knife is needed, the full sized PJ may be the tool just right for the job. The PJFZ has a wider blade, but with thinner profile for reduced weight while keeping a large profile for heavy work. A skeletonized version may be applicable for a flat and less intrusive mounting arrangement. I could go on and on here, but these details are usually provided quite well by the PJ, and if I don't have the knife design he's interested in, I'll make it.

5. Environmental considerations come later in the conversation, and are an important factor determining primarily the materials of construction, and secondly the finish. If the knife should withstand temporary marine exposure (salt water) than a high chromium stainless steel like 440C or CPMS30V will withstand corrosives better than most other steels. If the use will be in the desert with plenty of abrasive sand, a bead-blasted finish will work better. If the grind is very thin and the point of the blade made with a narrow cross sectional geometry, ATS-34 or CPM154CM may apply better due to their higher toughness or resistance to breakage. If wide ranges of heat and cold are expected, multiple sheaths may be required. The handle shape must accommodate grip in slimy, or even greasy exposures. These are all important considerations.

6. The service factor of a knife is seldom considered, unless you use a knife professionally like a Pararescueman will. The knife must be maintainable within the scope of knowledge of the PJ. He'll need to know how to sharpen it, clean it, maintain the knife, the sheath, and any accessories or mounts that ride along with the package. Some steels are too wear resistant to be sharpened in the field, some unusual geometries (like deep recurves) can only be sharpened correctly with large diameter ceramic rods. You certainly won't find any of those in the field! The finish should be regularly waxed, and that will depend on the exposures and frequency of use. The sheath and knife should be kept clean; if the sheath has a locking mechanism, it must remain clean to be operable. Even the accessories have to be cared for, checked for solidity and tightness, and inspected for ease of use.

7. Once the knife has been used, it must be re-sheathed. This seems so simple that it might not deserve discussion, but it does. Some knife designs, by nature of their blade shape are inherently difficult to sheath. Knives with straight or trailing points (where the point trails higher than the spine) require carful and slow movement into the sheath to prevent damage to the point and sheath bodies and welts. Dropped points are much easier to re-sheath. Knives with serrations have to be re-sheathed with some care and attention so that the teeth do not rip into the sheath or hang on any part of it. Blades with double edges require the most attention, as they have no safe areas except the handle. The sheath location is important. Guys like to think that a sheath in the middle of the back is cool, until they try to re-sheath a razor-tipped cutting edge aimed at their kidneys while blind to the task! Another consideration is the orientation of the knife and sheath mounts which can add difficulty to the re-sheathing operation.

Who knew there was so much to consider? If you are a professional knife user, you probably have already not only considered these points, but been frustrated by the limitations of most knives. I'm doing the best I can to help.

Thanks Jay.

We all really appreciated that you took time out of your day, as busy as you

are, to let us come by and check everything out. It was very impressive to

see all the work, skill and care that goes into the knives you produce. I

also wanted to express thanks for being so supportive toward what were trying

to do, and more so, the military in general. We all thought that was really

nice. I'm really excited about this knife, just the plastic cut out today

was neat, I cant wait to see the finished product.

Once again thanks,

--N.F.

USAF Pararescue

Hello Jay,

I was in the early stages of searching for a quality SRK and, eventually, I ended up on jayfisher.com.

Although I spent some of my younger years as a USAF forward controller, I have to admit that

I've never been much of a knife enthusiast. I really enjoyed the video on your homepage,

however, so I thought I'd type a few words of appreciation. Knife enthusiast or not, the underlying

message of self-sufficiency in your story really resonates with me. Please keep up the good work

and, even more importantly, keep spreading the word about old-world skills, problem-solving and

craftsmanship -- they're all dying concepts.

By the way, I was very pleased to see that you've dedicated some of your talent and vision to

military units like the USAF PJs. I trained and worked with some of them: and they clearly

deserve the recognition.

Have a good one,

--B.

When I started making knives for United States Air Force Pararescuemen, I couldn't help but admire these tough, highly trained, caring, and dedicated soldier-paramedics. I had served on several fire departments and emergency response teams and was a state registered Emergency Medical Technician myself, so that gave me some civilian background into life saving missions. While there is only the shadow of danger in civilian rescue when compared to combat rescue, many of the same concepts cross fields. My own father served in the Air Force, as did two other uncles and one son-in-law. Another uncle was a Marine. My father-in-law, my brother-in-law and my son served in the army, so the military background is prevalent in our family. So it was easy to find common ground with the PJs. Some of these guys, along with SERE professionals who affiliate with PJs became and will continue to be lifelong friends.

When I started working with Pararescuemen, it was all about the knives, but soon moved into other areas. Being a lifelong photographer, I started photographing PJs in their blocks of training, and some of those photographs still hang at the PJ School at Kirtland AFB in Albuquerque. I photographed them personally also, for their families and their own record during their training. I accompanied them for several of these field operations, and found their professionalism and honor to be of the highest caliber and order at all times. To keep up with them was a brutal challenge, and that was just training! I worked with Pararescue in several partisan training operations also as a civilian player and organizer, and was and still am an advocate for their professional field. It has always been, and will continue to be an honor.

I am humbled that PJs use and carry my knives in combat and civilian rescues and missions. Every year, I have patrons who anonymously donate to have me make PJ knives that I make for active duty use. This is a big deal, and I will continue to work with Pararescue as long as I am able to create and supply necessary tactical tools that they need but no one else will supply.

It is stunningly powerful to know that some of the knives have been with PJs when they have given their all in battle. This is a very serious world, extremely dangerous, and haltingly unfair. Defending our freedom and saving others who do so with the ultimate sacrifice is something that few individuals would ever understand, much less do. Yet Pararescuemen offer their all so that others may live.

Below is a group of knives that are either direct Pararescue designs, or knives that are Combat Search and Rescue designs typical of my Pararescue or even SERE style. These are knives that are based on PJ design and use criteria, PJ durability, strength, and task oriented designs. Some of them even have gemstone handles and exotic knife sheaths. The PJ influence flows through many of my knife works.

| Main | Purchase | Tactical | Specific Types | Technical | More |

| Home Page | Where's My Knife, Jay? | Current Tactical Knives for Sale | The Awe of the Blade | Knife Patterns | My Photography |

| Website Overview | Current Knives for Sale | Tactical, Combat Knife Portal | Museum Pieces | Knife Pattern Alphabetic List | Photographic Services |

| My Mission | Current Tactical Knives for Sale | All Tactical, Combat Knives | Investment, Collector's Knives | Copyright and Knives | Photographic Images |

| The Finest Knives and You | Current Chef's Knives for Sale | Counterterrorism Knives | Daggers | Knife Anatomy | |

| Featured Knives: Page One | Pre-Order Knives in Progress | Professional, Military Commemoratives | Swords | Custom Knives | |

| Featured Knives: Page Two | USAF Pararescue Knives | Folding Knives | Modern Knifemaking Technology | My Writing | |

| Featured Knives: Page Three | My Knife Prices | USAF Pararescue "PJ- Light" | Chef's Knives | Factory vs. Handmade Knives | First Novel |

| Featured Knives: Older/Early | How To Order | Khukris: Combat, Survival, Art | Food Safety, Kitchen, Chef's Knives | Six Distinctions of Fine Knives | Second Novel |

| Email Jay Fisher | Purchase Finished Knives | Serrations | Hunting Knives | Knife Styles | Knife Book |

| Contact, Locate Jay Fisher | Order Custom Knives | Grip Styles, Hand Sizing | Working Knives | Jay's Internet Stats | |

| FAQs | Knife Sales Policy | Concealed Carry and Knives | Khukris | The 3000th Term | Videos |

| Current, Recent Works, Events | Bank Transfers | Military Knife Care | Skeletonized Knives | Best Knife Information and Learning About Knives | |

| Client's News and Info | Custom Knife Design Fee | The Best Combat Locking Sheath | Serrations | Cities of the Knife | Links |

| Who Is Jay Fisher? | Delivery Times | Knife Sheaths | Knife Maker's Marks | ||

| Testimonials, Letters and Emails | My Shipping Method | Knife Stands and Cases | How to Care for Custom Knives | Site Table of Contents | |

| Top 22 Reasons to Buy | Business of Knifemaking | Tactical Knife Sheath Accessories | Handles, Bolsters, Guards | Knife Making Instruction | |

| My Knifemaking History | Professional Knife Consultant | Loops, Plates, Straps | Knife Handles: Gemstone | Larger Monitors and Knife Photos | |

| What I Do And Don't Do | Belt Loop Extenders-UBLX, EXBLX | Gemstone Alphabetic List | New Materials | ||

| CD ROM Archive | Independent Lamp Accessory-LIMA | Knife Handles: Woods | Knife Shop/Studio, Page 1 | ||

| Publications, Publicity | Universal Main Lamp Holder-HULA | Knife Handles: Horn, Bone, Ivory | Knife Shop/Studio, Page 2 | ||

| My Curriculum Vitae | Sternum Harness | Knife Handles: Manmade Materials | |||

| Funny Letters and Emails, Pg. 1 | Blades and Steels | Sharpeners, Lanyards | Knife Embellishment | ||

| Funny Letters and Emails, Pg. 2 | Blades | Bags, Cases, Duffles, Gear | |||

| Funny Letters and Emails, Pg. 3 | Knife Blade Testing | Modular Sheath Systems | |||

| Funny Letters and Emails, Pg. 4 | 440C: A Love/Hate Affair | PSD Principle Security Detail Sheaths | |||

| Funny Letters and Emails, Pg. 5 | ATS-34: Chrome/Moly Tough | ||||

| Funny Letters and Emails, Pg. 6 | D2: Wear Resistance King | ||||

| Funny Letters and Emails, Pg. 7 | O1: Oil Hardened Blued Beauty | ||||

| The Curious Case of the "Sandia" |

Elasticity, Stiffness, Stress, and Strain in Knife Blades |

||||

| The Sword, the Veil, the Legend |

Heat Treating and Cryogenic Processing of Knife Blade Steels |