Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Cassiopeia"

Beyond simple tools: fine instruments and professional works of art.

Making a legacy chef's knife set for a great custom knife client is a big honor. My client requested a useful and beautiful pair of knives, one he can treasure as a heritage set, lasting for generations. It was my job to create this as a striking work of art and science. What a great task; I truly love this challenge!

Thanks for patiently reading over this page. I was enthralled with this piece, and I'll try to present it as if we were opening a Christmas or Birthday present together. I've taken over 50 photos of the work, so I can always enjoy it, wherever it lives.

Thanks, T. S.!

The first detail most people will notice about the hardwood case is the intricate double dovetail accents. My client requested a lighter color of hardwood, so I built this one in straight-grained maple, with a light cherry finish. This is a very tough, durable wood. The double dovetails in the joinery are true dovetails and tightly fitted with accents of American Black Walnut. The lid of the case is Bird's Eye Maple and the feet are all maple hardwood.

I wanted a compact, yet massive and stable case, one worthy of a countertop in a fine kitchen. The case is deep and has some nice features and at least one surprise hidden away. I chose a clear finish of acrylic lacquer for easy cleaning. Note the nice hinges I handmade for this substantial piece; I machined them from solid 304 austenitic stainless steel for zero corrosion problems ever. They are sturdily mounted to the hardwood case with all 304 stainless steel fasteners. I positioned a nice grain accent in the maple at the rear of the case; every surface should have some nice visual interest. The base and the lid I made in a Roman "pillar" type of style, echoed in the legs. By the way, the legs don't touch the countertop; they are lifted with large durable neoprene feet, so spills can't get on the wood. It is a kitchen, after all!

A nice little bauble rests at the side of the case; it's a small handle I made out of solid 304 polished stainless steel, of course, for zero care ever. It's the handle for a nice long drawer also made of straight maple hardwood.

The drawer has a snugly fitted prise of hand-cast, high strength silicone rubber. I dyed this prise a "milk chocolate" brown, a nice working utility color, and cast my maker's mark in the mold.

The drawer holds the tough silicone rubber prise for the double-sided diamond sharpener. The prise isn't just a cozy drawer offering padding for the sharpener; the silicon is "grippy" and allows my client to place the sharpener in the prise on any hard surface (think countertop or tabletop) and sharpen the knife without worrying about the sharpening "stone" sliding around. The silicone stays put while the careful strokes on the diamond pad hone up the steel. This will only have to be done rarely; perhaps once or twice a year. In my own chef's knife, I sharpen it once a year and use it daily. This is the advantage of a high quality, properly cryogenically treated high alloy stainless steel blade, which we'll get to, below!

Of course, the sharpening stone is reversible; why not take advantage of modern diamond abrasives? This one is made by DMT, a great company. The "blue dot" side has 45 micron (325 mesh) diamond, and the "red dot" side has 25 micron (600 mesh) diamond abrasive set in plated nickel on a super tough cast resin body. These stones are very similar to the ones I use to sharpen every knife I make, and they last indefinitely.

Now that we've stored the sharpener, prise, and drawer back in its resting place, let's take a bird's eye view of the case lid. And, of course, it's Bird's Eye Maple. This is a very hard, tough wood, with sweet little eyes and satiny rays throughout, and is actually very difficult to photograph. The cat's eye effect is only visible as your viewing position changes, which we can't do here, and I didn't take a video, but that's an idea for the future!

And now we lift the lid! Wow. Just Wow. It's a real treasure inside, many inches of magnificent powder metal technology steel, striking hand-cast silicone prise and breathtaking gemstone. My, my, a feast for the eyes, I love this set!

The lid has a positive stop at about 110° opening, because I handmade the very robust hinges in solid 304 stainless steel throughout. This is just the right angle for the lid stop I built into the hinge design, the hinges are tight and completely non-corrosive and waterproof, and will absolutely outlast the box and you and me, too. If my client is like me, his family will be opening and closing the box several times a day, for decades.

Look at this nice detail on the silicone prise. I cast this prise by hand, by first building an custom mold and hand-dying and pouring the silicone. Silicone is grippy and stiff, and holds great detail and incredible longevity. I wanted the color to compliment the knives and case, so I carefully mixed, blended, poured and interplayed the color scheme to get the right combination I wanted reddish clouds with black shadowy accents in a milky sky, reflecting the color play in the gemstones. Though it's a strong pattern, it's not too overbearing and compliments the gemstone crystals nicely.

I admit that I did have an extra pair of hands in this very difficult task, as pouring the silicone requires degassing multiple color blends under a high vacuum pump in stages, while the mixing and pouring (pot life) is critical and exact. Thanks then, to my wife Amy for her careful hands assisting me!

I just had to elaborate more on the prise and case. In the photo above, I've removed the knives for a better look. The "cutouts" for the knives are custom made for these particular knives, and they are crisp and sized just right to allow the knives to sit safely, yet not tightly, since silicone is "grippy." Because of the silicone's flexible nature, the prise is safe for the knife cutting edges, and it doesn't slice in normal use. My own prise in my own kitchen looks brand new, even after many years of use. Note also the "pluck holes," the cutouts around the handles that will allow the fingers to pick up the knives. We blended dark red, black, and clear silicone for this casting, and it stands out well, matching the gemstone.

Looking at the extreme right edge of the silicone prise, you'll notice a shaped handle made of maple, with finger indents. This is how the prise and its supporting panel are lifted and removed from the case.

In the photo above, I've removed the prise from the case, so you can see the handle mounted to the red oak plywood panel that supports the prise. You can see the thickness of this massive prise as well, over an inch thick and weighing four pounds. That's a lot of silicone! A four pound prise is heavy and stable, and can be used out of the case just as you see here, directly on the countertop. Because of the weight and because it's grippy, it will not slide around. Also, cleaning is incredibly easy, usually only requiring a rinse, since it's silicone and nothing really sticks to it. By the way, it's not just any silicone, it's high strength, and high temperature resistant 800 PSI tensile strength silicone. If you wanted to, you could bake in this stuff, as it resists over 400°F. Okay, it wouldn't work well for cooking, because it's so massive it would take too long to heat up, but you could, if needed, set a hot pot right on top of it with no damage.

If my client wanted to use it that way, he'd have to find another place for his knives, but after that, he might just flip it over:

...and (photo above) this is what the bottom looks like. Beautiful, elegant, and classy. You can read more about my silicone prises at this link on my Chef's and Kitchen Knives page.

But more likely, my client may choose to have the knives accessible, should he have a heavy group of cutting tasks, or maybe a big dinner party, or some event where he prefers the knives to boldly claim some real estate on his countertop rather than be secreted away in the case. The photo above illustrates that option. By the way, the blades are facing away from the user on purpose, as they are like giant, hollow-ground razor scalpels... as they should be. So the prise is mostly about safety when the knives are not being used.

Speaking of "secreting" away, look at this nice secret compartment that hides below the prise support panel. It's a nice place to store something, and fairly sizeable, at 16" long, 4.5" wide, and 1.4" tall. Since the prise is somewhat grippy, someone unfamiliar with the setup might think that the prise couldn't be removed from the case, thus hiding the chamber beneath the panel. It's just a nice additional feature and everyone likes a secret compartment!

Before we leave the case, here's a view of the bottom. I've engraved a nice permanent legend plate for the bottom, mounted and sealed with acrylic for longevity, describing the materials and condition. Also notice the neoprene feet, which keep the case off of the counter in case of spills, as well as providing some leveling balance (think of a tile countertop). Notice also the thickness of the stainless steel hinges. Sturdy!

You'll also see a few of the stainless steel fasteners, square drive screws. They strengthen the case, but it really can't be taken apart, because I assembled it completely with waterproof high strength wood glue.

Now, on to the stars of the show. Beautiful, elegant and clean, I can't say enough about these knives. My client requested a larger pattern of my Concordia chef's knife, a popular "Sabatier" but with a long, large blade. He complimented it with my "Sanchez" design, a stout, mid-sized knife with a comfortable handle. These are great designs, and very popular for a reason. With these two knives, you've got nearly all of your chef's cutting chores done; you just need to grab them and get to work.

Here's my beautiful take on the +9" edged Concordia. Already a popular design, the extra length blade brings this knife to a large, robust tool ready for any task. Surprisingly, it's not very massive-feeling at all, because it's incredibly thin at the cutting edge and in the hollow grind with a fairly thin spine as well. I ground it with a 12" diameter wheel, so that creates a very wide hollow grind and extreme longevity, even after decades of sharpening. In my own chef's knife, I only sharpen once or twice a year, and I use it daily.

I can make these high alloy steel blades incredibly thin and tough and hard because of my advanced heat treating methods. If you hadn't guessed by now, I'll put my heat treating against anyone else's in the modern knife world for outright performance and measurable results. This is my T4 process and you can read about it here. Essentially, it's a deep cryogenic process that takes over a week, including an extended deep cryogenic soaking time with multiple tempers and carefully staged cryogenic immersions. Yes, it's complicated, and no one else does this, but the results are stupendous, they are like nothing I've ever experienced, and one of the things my knives are known for. The steel my client requested is CPM 154CM; that's a special powder metal high molybdenum, high carbon, high chromium martensitic stainless steel made by Crucible industries. It's very, very good stuff, and difficult to do well. The finishes are complete mirror, and the grinds even and smooth throughout.

Notice the extended double heel at the beginning of the cutting edge. This edge is so incredibly sharp that I didn't want the chance of my client's finger contacting the edge, so it's moved forward slightly for safety. The point of the blade has a somewhat thicker grind, supported by the close spine. The knife is surprisingly comfortable to use; I like this modification of my original Concordia design so much, I'm making more of them.

Just above is the same knife blade, but with an extended front bolster and the same handle material. For details on this and more photos, please click on this link, lower in this page, describing the change order.

Above is the "Sanchez" design, a wonderful medium-sized knife, and this one is extra sturdy. I tempered it at a high hardness of 61.5 HRC, and it has the thickness in the blade to support it. It's a stiff, tough knife with a well-shaped and contoured handle that is comfortable and solid. The point encourages many piercing and cutting tasks for the chef, and the mirror polish makes for easy clean-up. This is a very popular design of mine, just a complete workhorse of a knife.

The Sanchez is made of the same materials, and the gentle sweep of the point with the well-contoured and rounded grip means it will probably be the most reached for knife in the set.

Let's sneak up on the gemstone handles a bit, just for fun. Notice the doublet-mount I chose for these knives; this is Red River Jasper from Africa alongside the fully tapered tangs. It has a bold character, with some bands of solid agate and white and translucent areas within. It makes a serious color statement, and rigidly supports the proud gemstone of the handle face.

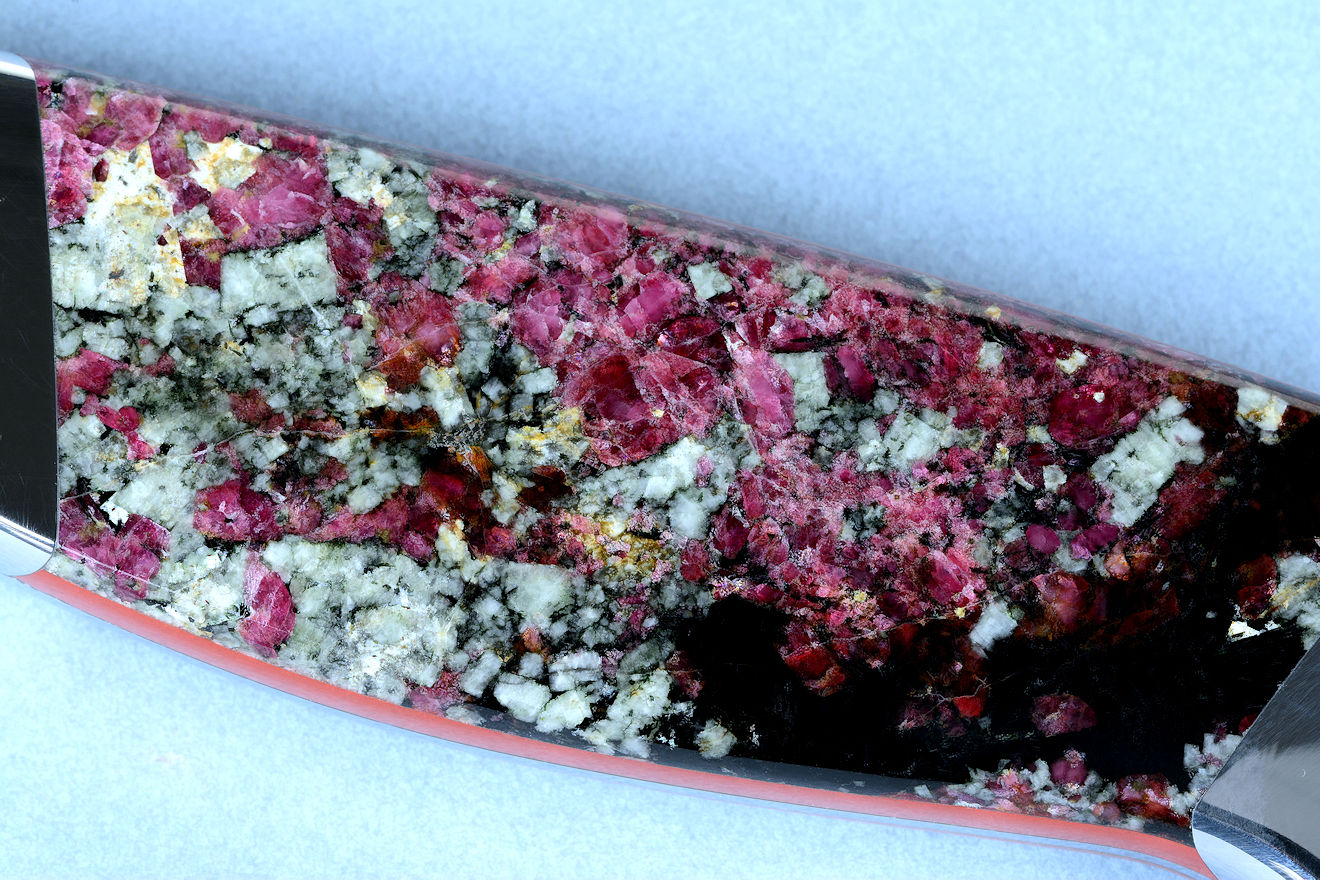

And BANG! Wow, this is why I love gemstone. My client requested Eudialite gemstone from Russia; this gorgeous crystalline magnificence was created deep beneath the surface of our earth. It's amazing to think that this is what our feet walk upon! Do we deserve this? Maybe not, but clearly Someone has other plans.

Eudialite is a gemstone from the Kola Peninsula in Russia. This is a cyclosilicate mineral, with violet-red hexagonal crystals throughout, all oriented in different directions. The eudialite is in association with microcline, nepheline, aegirine, lamprophyllite, lorenzenite, murmanite, and other minerals. This beautiful stone is considered a collector's stone. It's a minor ore of zirconium and contains significant amounts of rare earth elements. Rare and beautiful, indeed!

Here's another great magnification of the handle. This is about a 7 power enlargement, and worth a look. Stunning, just stunning. More photos at the bottom of the page.

I'm very proud to have my maker's mark on these fine knives; I'm honored to have made this magnificent custom pair for a great client for his most precious knife use, the kitchen where his family prepares meals.

Please look over the specifications and details as well as additional photographs below.

Thanks, T. S.!

Thanks, T. S.!

Hello Jay!

The knives arrived a couple hours ago and I am so stoked!!

I haven't gotten to use them yet but I have a big meal to

cook on Friday and will be breaking them in them. Even so,

I wanted to write to you and say THANK YOU!!!!

Your thoughtfulness on every aspect of the knives, case, and prises shows. The case is fantastic and fits perfectly on our counter. I read your note and the there is no issue with the height of the feet and they look great. Each piece of wood is beautiful and I really like the black walnut accents in the dovetail joints! The prise is so cool and you definitely achieved the look of red clouds in a milky sky.

Most importantly, the knives are perfect! I am amazed by the mirror polish you achieved and the fit of every piece is astounding. The Sanchez is perfection for a utility knife. The size and shape of the blade and handle make it just right for all the various tasks outside of chopping. The pieces of red river jasper that you used in the handle for the Sanchez kind of steals the show even from the beautiful eudialite. They are such a beautiful shade of red! The Concordia is incredible and the perfect length. The eudialite in the Concordia handle is so interesting and really shows off the stone. I love the shape of the blade! It has the slightest arc so that it rocks beautifully from tip to heel which will be so nice chopping, dicing, mincing.

Holding these and seeing the culmination of your brings to mind 1 Cor. 10:31: "Therefore, whether you eat or drink, or whatever you do, do all to the glory of God." The fact that such beautiful and functional pieces of art are possible by human hands is a reflection of the image of God in man and all that He built into this world He created and continues to sustain.

Thank you again Jay!

T.

After my client used the knives, we both realized that I had made an error in his custom order. He had ordered an extended front bolster, which I had missed in the order write-up, and so he sent the Concordia back to be re-bolstered and re-handled. This is a very tricky process, considering I had to match the whole scheme of the original gemstone. I was lucky to have just enough of the eudialite and jasper to match and so I corrected the knife with the front bolster and handle change. The results are just below:

Hi Jay,

Just wanted to let you know that I picked up the knife yesterday and it is amazing.

The handle feels great and looks great! This will be a treasure in our home for the

rest of our lives. Thank you for all of your hard work and craftsmanship and I pray

that God continues to bless you and your family!

--T.

| Main | Purchase | Tactical | Specific Types | Technical | More |

| Home Page | Where's My Knife, Jay? | Current Tactical Knives for Sale | The Awe of the Blade | Knife Patterns | My Photography |

| Website Overview | Current Knives for Sale | Tactical, Combat Knife Portal | Museum Pieces | Knife Pattern Alphabetic List | Photographic Services |

| My Mission | Current Tactical Knives for Sale | All Tactical, Combat Knives | Investment, Collector's Knives | Copyright and Knives | Photographic Images |

| The Finest Knives and You | Current Chef's Knives for Sale | Counterterrorism Knives | Daggers | Knife Anatomy | |

| Featured Knives: Page One | Pre-Order Knives in Progress | Professional, Military Commemoratives | Swords | Custom Knives | |

| Featured Knives: Page Two | USAF Pararescue Knives | Folding Knives | Modern Knifemaking Technology | My Writing | |

| Featured Knives: Page Three | My Knife Prices | USAF Pararescue "PJ- Light" | Chef's Knives | Factory vs. Handmade Knives | First Novel |

| Featured Knives: Older/Early | How To Order | Khukris: Combat, Survival, Art | Food Safety, Kitchen, Chef's Knives | Six Distinctions of Fine Knives | Second Novel |

| Email Jay Fisher | Purchase Finished Knives | Serrations | Hunting Knives | Knife Styles | Knife Book |

| Contact, Locate Jay Fisher | Order Custom Knives | Grip Styles, Hand Sizing | Working Knives | Jay's Internet Stats | |

| FAQs | Knife Sales Policy | Concealed Carry and Knives | Khukris | The 3000th Term | Videos |

| Current, Recent Works, Events | Bank Transfers | Military Knife Care | Skeletonized Knives | Best Knife Information and Learning About Knives | |

| Client's News and Info | Custom Knife Design Fee | The Best Combat Locking Sheath | Serrations | Cities of the Knife | Links |

| Who Is Jay Fisher? | Delivery Times | Knife Sheaths | Knife Maker's Marks | ||

| Testimonials, Letters and Emails | My Shipping Method | Knife Stands and Cases | How to Care for Custom Knives | Site Table of Contents | |

| Top 22 Reasons to Buy | Business of Knifemaking | Tactical Knife Sheath Accessories | Handles, Bolsters, Guards | Knife Making Instruction | |

| My Knifemaking History | Professional Knife Consultant | Loops, Plates, Straps | Knife Handles: Gemstone | Larger Monitors and Knife Photos | |

| What I Do And Don't Do | Belt Loop Extenders-UBLX, EXBLX | Gemstone Alphabetic List | New Materials | ||

| CD ROM Archive | Independent Lamp Accessory-LIMA | Knife Handles: Woods | Knife Shop/Studio, Page 1 | ||

| Publications, Publicity | Universal Main Lamp Holder-HULA | Knife Handles: Horn, Bone, Ivory | Knife Shop/Studio, Page 2 | ||

| My Curriculum Vitae | Sternum Harness | Knife Handles: Manmade Materials | |||

| Funny Letters and Emails, Pg. 1 | Blades and Steels | Sharpeners, Lanyards | Knife Embellishment | ||

| Funny Letters and Emails, Pg. 2 | Blades | Bags, Cases, Duffles, Gear | |||

| Funny Letters and Emails, Pg. 3 | Knife Blade Testing | Modular Sheath Systems | |||

| Funny Letters and Emails, Pg. 4 | 440C: A Love/Hate Affair | PSD Principle Security Detail Sheaths | |||

| Funny Letters and Emails, Pg. 5 | ATS-34: Chrome/Moly Tough | ||||

| Funny Letters and Emails, Pg. 6 | D2: Wear Resistance King | ||||

| Funny Letters and Emails, Pg. 7 | O1: Oil Hardened Blued Beauty | ||||

| The Curious Case of the "Sandia" |

Elasticity, Stiffness, Stress, and Strain in Knife Blades |

||||

| The Sword, the Veil, the Legend |

Heat Treating and Cryogenic Processing of Knife Blade Steels |