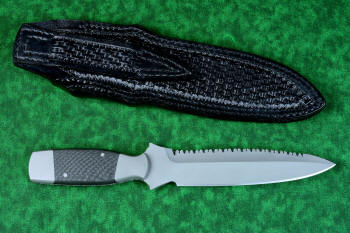

Lynx Custom Knife

"Lynx" Custom Professional Tactical,

Counterterrorism Knife

- Size: Length overall: 10.8" (27.4 cm), Blade Length: 6.0" (15.2 cm), Thickness: 0.211" (5.4 mm)

- Weight: Knife: 10.5 oz. (298 grams) Sheath HTL-TW: 9.5 oz. (269 grams), Leather: 6.0 oz. (170 grams)

- Blade: ATS-34 high molybdenum martensitic stainless steel blade, T3 deep cryogenically treated with triple tempering to 59.5 HRC, media blasted flat

- Sheath: Tab-wedge hybrid tension in kydex, anodized 5052H32 aluminum, blackened 304 stainless steel, anodized 6AL4V titanium

- Sheath: Hand-stamped black basketweave 9-10 oz. leather shoulder

- Hardware, Fasteners: 304 stainless steel, darkened, 6AL4V anodized titanium, 5052 H32 high strength aluminum alloy, anodized

- Duffle: 1000 Denier Cordura Ballistic Nylon, polypropylene, polyester, nylon, blued steel, embroidered tags

- Knife: Made for a great client to his

specifications, this is my Lynx tactical dagger. This is a great

knife, stout and compact, slender and serious, what we call in the

field a "fast" knife. This is due to its compact size and light

weight, and ability to be brought into action quickly and smoothly.

I named this design the Lynx because of the dangerous speed and

claws of the animal.

- The Steel I chose for the Lynx

blade is ATS-34, a high

molybdenum martensitic stainless steel. The molybdenum aids in

forming nucleation sites for complex carbide development,

and when properly treated, increases the toughness dramatically,

resulting in a blade that's extremely durable. This allows

me to temper the steel at a higher overall hardness

(59.5 HRC), producing a rigid blade. This also means

great wear resistance and less sharpening throughout the

life of the knife. The high chromium and high

carbon results in profuse chromium carbides, increasing

corrosion resistance as well as wear resistance. To bring

this steel to its zenith, I used my proprietary T3 deep

cryogenic process in heat treating this blade; it's a highly

detailed, extremely sophisticated process that takes 33

individual steps and takes over a week long. The result of this is an

incredibly wear-resistant blade that has extremely high carbide

development, fine grain, and extremely high toughness. Asperity is

reduced; the microstructure development is superior to any other

typical handmade knife, and far above any factory or

manufactured knife. This is, simply put, ATS-34 at its very finest

advanced condition.

- The Blade is a special shape, it's a

tightly hollow ground dagger, what might be called a "spear"

because the blade profiles are almost identical. It's the

difference that matters, and the central spine apex is

offset. This is called a "differential" grind. The main blade is razor keen and even, and is ground

with an 8" contact wheel for a broader hollow grind, and

thinner cutting edge. The top edge is hollow ground with a

3" contact wheel, for a tight radius, and high strength, and

has my "microblade" serrations. These are small, extremely

sharp blades spaced between alternating deeper scalloped

cuts. These serrations are surprisingly aggressive, and not

prone to hanging up or snagging. The blade has large

quillons to protect the hand from sliding forward onto the

edges. The dominant factor of this knife is the offset thick

spine, with substantial strength all the way to the piercing

tip. There is no flex in this blade.

- The knife feels like a solid mass in

the hand, yet the blade seems light and formidable. The

balance point is exactly at the forefinger grooves.

- The handle is all business, it's built on at tapered

tang that has substantial thickness at the butt. The tang is

fully fileworked with an aggressive "thorny vine" pattern

for increased purchase and handmade distinction. The knife

is bolstered with 304 high chromium, high nickel austenitic

stainless steel bolsters for zero care, and they are

dovetailed to bed a pair of very technical, high strength

carbon fiber scales. The curve of the handle is just right;

it is swallowed in the hand and feels solid and secure. The

entire handle, like the blade, is media blasted for a flat,

non-reflective finish.

- Sheath: NEW! The sheath is an advanced evolution of my hybrid tension-locking sheath, a wedge-opening model.

- Materials: It's built on a frame

of 5052 H32 corrosion-resistant high strength aluminum alloy welts.

The individual welts are then anodized for a full mil of thickness,

twice the thickness of typical anodizing. The anodizing creates a

built-up near-ceramic hard surface on the aluminum, and it's

entirely corrosion-resistant and non-conductive. It's permanently

dyed (in black) and sealed with a solution that inhibits ultraviolet

degradation of the dye and anodized surface. In fact, all of the

aluminum components in this assembly are the same alloy

and are treated this way; this is

the most advanced condition that will even withstand marine use. The sheath front and

back are double-thickness kydex, twice the thickness of typical

knife sheaths, and the sheath is bonded with waterproof marine-grade

cement and secured with darkened 304 stainless steel

Chicago screws.

- Layout: As with all of my sheaths, they are built on a 2.5"

center hole pattern, so the components can be moved around an

mounted in various positions on the sheath. As with all

of my tactical sheaths, this one is completely reversible

for as many wear options as possible. Most of my accessories can be used on this

sheath, including any new ones I develop.

- Horizontal Belt Loop Plates for horizontal belt or webbing wear,

welded for ultimate strength and light weight,

reversible, and in black anodized aluminum.

- Flat mounting straps for rigid clamping to

webbing, belts, or gear in vertical or horizontal

orientation in black anodized aluminum.

- Low profile belt loops

(footman's loops): for tactical webbing belts with

maximum .190" thickness and 1.5" width in black

anodized aluminum

- High profile belt loops

(footman's loops): for tactical webbing belts with

maximum .250" thickness and 1.5" width in

black anodized aluminum

- High profile wide belt loops

(footman's loops): for tactical webbing

belts with maximum ..250" thickness and 1.75" width

in black anodized aluminum

- All necessary stainless steel hardware, fittings, fasteners and tools for mounting, moving, and adjusting

- Tab-Wedge (TW) Release: An advanced feature of

this knife sheath is the security and retention

mechanism. I've used my standard hybrid tension lock, so the knife

can be retained with the pressure of an anodized 6AL4V titanium

dog-leg spring, and I've included three of those so the

user can choose which strength to apply. In an

emergency, the ball and spring can be deflected with a hard

tug, and I wanted to leave that choice to my client if he

wished for a standard setup. However, because of the proximity of the

serrations to the ball-lock, I've created the tab-wedge (TW)

release to allow the ball to clear the knife blade area

completely, with the pressure of the thumb. This also makes

sheathing and unsheathing a one-hand certain operation.

Here's how it works: when sheathed, the tension-lock

mechanism works as normal. The knife is retained in the

sheath by the pressure of the ball delivered through the

titanium spring, against the inside curve of the bolster.

When the user needs the knife, he simply pulls the tab

toward his hand with his thumb, and the wedge lifts the titanium spring and ball

away from the knife, clearing the blade, the serrations, and leaving

the entire mouth of the sheath open. Then, the knife is unsheathed.

It takes much more effort to describe it than to use it; the motion

is natural with the thumb. You wrap your hand around the handle,

pull-flip the tab-wedge, and extract the knife. Reinsertion

is just as simple; you slip the knife in the sheath (as the ball and

is completely out of the way) and then use the thumb to

push-swivel the tab forward, closing the ball on the thumb rise, and locking the

knife in the sheath. Because I've built these sheaths to be

completely reversible, I've included two tab-wedges, one for

each side. If my client wants to forego the locking-tab-wedge

entirely, he simply replaces the post mounted to the rotating tab

with a standard Chicago screw post, and he then has the typical

hybrid tension-lock. However in this design of knife,

the serrations may contact the ball and this will not be a

good outcome. It won't hurt the blade, but the ball will be

damaged. In an emergency, the owner probably won't mind, as

he needs his knife immediately, so I left that option. Improving this design is representative to

my commitment to excellence in service to the people who

purchase and depend on these knives, and it's an honor to design

these for the hardest of environments and use.

- Sheath: Black basketweave leather is a classic,

and this is a special one. Because this knife is double-edged and

frankly, dangerous to contact at the blade, I've designed and made

an extremely deep and protective leather sheath, hand-stamped

basketweave pattern, double row stitched it throughout with

polyester high strength thread, dyed it black, and finished it with

lacquer. This is a tight, deep sheath, not one the knife will easily

be removed from, for a reason. That reason is that the protection of

the wearer is the first concern in the building of a knife sheath, so it's built

around substantial welts and made of 9-10 oz. thick leather

shoulder. It takes a manly hand to unsheathe the Lynx, and that is

how it should be on this type of knife. Even the belt loop is tough and double-row

stitched for strength.

- Containers, Instructions, Archival: included are tin plated

steel containers for the fasteners and hardware, and the

instructions for the rig including a checklist for the

kit. Included is an engraved co-extruded acrylic archival plate.

- Mini-Duffle: One thing I found out over the

years was a need to store these components that was as tough and

durable as what they contained. This is why I make the duffles, in

my studio, by hand. I make them in 1000 Denier Cordura ballistic

nylon, which is coated on the inside with polyurethane for moisture

resistance. This is some very tough stuff, and I triple-stitch the

seams, all in heavy polyester thread. I've included steel D-rings at

the zipper stops on the ends for several reasons: to mount accessory

straps or carry options, to clip accessories, and to oppose the

zipper when pulling open. Otherwise, you have to pinch the material

to open the zippers with one hand and pull the zipper pull with the

other. I've used double zipper pulls.

The design of the duffle is a box-end, so that the duffle stores

neatly, and it's not too big but accommodates the kit well, with

some room to spare. It has my "Jay Fisher Knives" embroidery, and opposing that is a hook and

loop stitched tag mount, with a removable embroidered identifier of

the knife pattern. This is important when clients have more than one

knife. These duffles are so great, I have clients buying them

alone without a knife, for their friends and other stowed gear!

- The Lynx is a great custom tactical and counterterrorism knife,

complete with professional gear.

Thanks, P. K.!

They arrived today. I expect perfection and you delivered as always.

The kits were a surprise to me. I know this sounds stupid to you, but, I am so use to

a masterpiece and a sheath to be put on display. The embellishments, on the weapons, cause

one to look at them as art pieces and not weapons of war. The kits bring home the seriousness

of your works and the need for full kits. In the future I will get full kits.

I would guess the majority of patrons do not truly understand what you do. The trolls and detractors

miss the mark completely. Your creations mean the difference between life and death.

Yours Truly:

P.

Please click on thumbnail knife photos