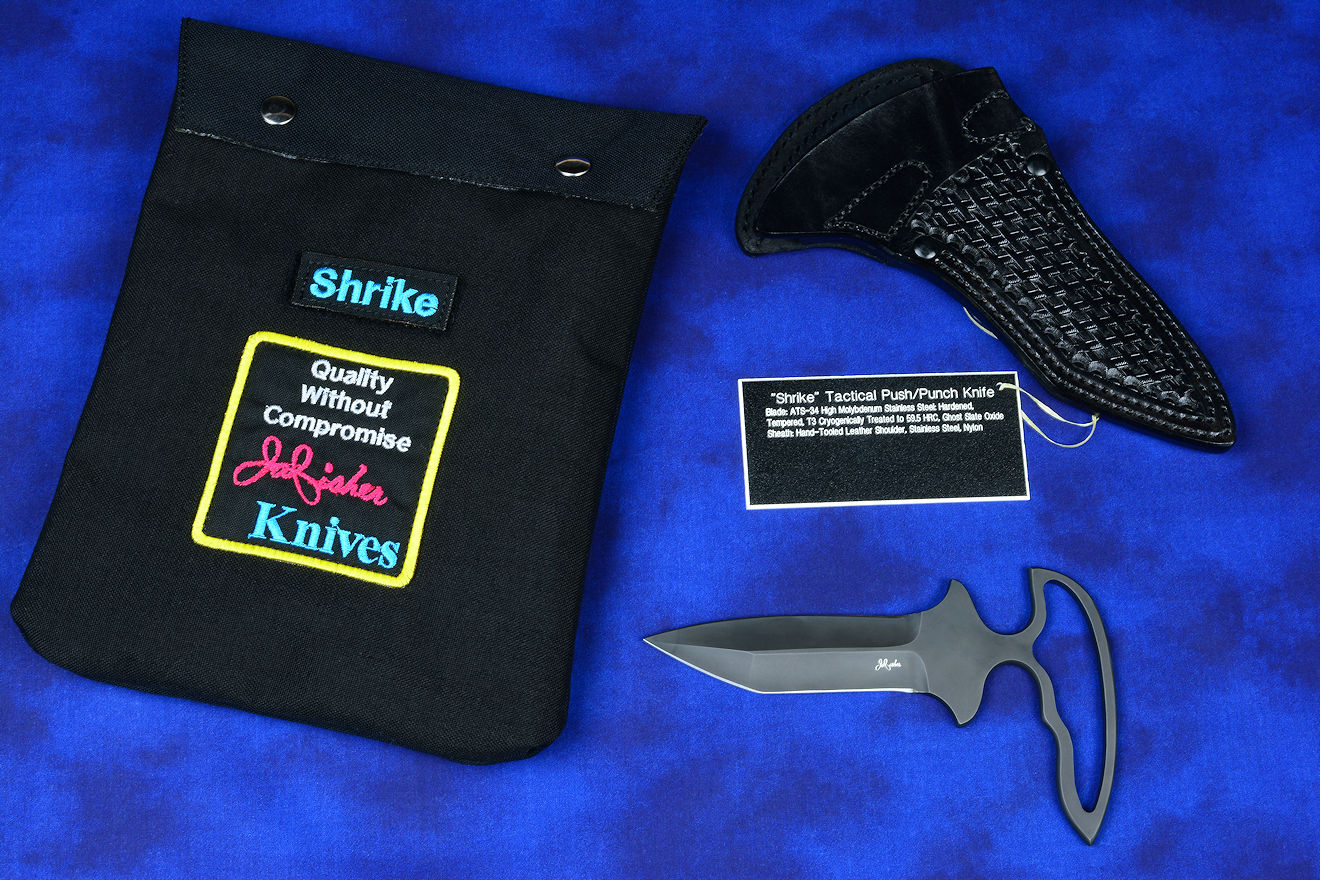

"Shrike" Tactical, Utility Push, Punch Dagger/Knife

NOTICE!

I've made a new layout for the tactical knife descriptions, seen

on this page. I've separated the

components, briefly describing them in individual boxes. In those boxes

are links to dedicated pages describing everything about the part,

component, or accessory. The pages are substantial, and offer the

history, operation, materials, use, mounting, and care of each

accessory.

"Shrike" Tactical, Counterterrorism,

Push-Punch Dagger/Knife (Shadow Line)

With Post-Locking Heavy Leather Sheath

Designed for serious counterterrorism, PSD, and personal defensive use, this is a top-of-the-line,

extremely tough and corrosion-resistant knife and basic sheath.

NO OTHER SOURCE can supply what you see here, all finely handmade to

work when you most depend on it: safe when sheathed, lightweight and

ultimately useful when in hand.

Thanks, J. V.!

Included:

The Knife

- Size: Length overall max: 7.8" (19.8 cm), Width max at handle: 4.5" (11.4 cm), Blade Length at cutting edge: 4.5" (11.4 cm), Thickness: 0.250" (6.5 mm)

- Weight: 6.7 oz. (190 grams)

- Blade: ATS-34 High Molybdenum Martensitic Stainless Tool Steel, Hardened and Tempered, T3 Specialty Cryogenically treated to Rockwell C59.5, proprietary surface oxide treatment "Ghost Slate."

- Type/Purpose/Origin: Answering requests for an ultra

lightweight yet tough and wear-resistant push-punch dagger that

would function as a crossover between

tactical/counterterrorism/combat use and daily working and carry, I

designed my "Shrike" pattern. The name comes from a carnivorous

bird of the Laniidae family, which is Latin for "butcher." It's a

bird that wears a dark mask, and is also known as a "butcherbird,"

because of its aggressive feeding habits. It suited the knife

pattern well.

- Blade Steel Alloy: The Shrike blade is

made in ATS-34, a hypereutectoid, martensitic high

molybdenum stainless tool steel. In this steel, there are three significant

alloys that work together to make an extremely tough and

durable wear-resistant steel

with high corrosion resistance. First, there is

carbon, at 1.25 percent, allowing significant hardening and

forming of carbides. The second is chromium, and at 14

percent, it's a true stainless steel with high corrosion

resistance. The third and most effective is molybdenum.

ATS-34 has 4% of molybdenum, allowing a very high concentration of

molybdenum carbide particles, which are extremely wear-resistant

and contribute greatly to carbide formation at grain boundaries,

leading to overall stabilization of the microstructure and

leading to higher toughness overall. This means that

ATS-34, when properly treated, is highly resistant to breakage, even at a

high hardness. These three alloy elements combine to form very hard

vanadium carbides and chromium carbides, particles so hard that

typically diamond is preferred to sharpen this blade effectively.

- Heat Treatment: This Shrike has my T3

heat treatment, yielding an astounding blade in incredible

condition through advanced processing protocols. How advanced is

this treatment? It's a multi-stage cryogenic treatment,

involving temperatures ranging in over 2000°F (1090°C)

to -320°F (-196°C). The process is an evolution of my

advanced heat treating processes, and consists of 33 dedicated

and specific steps and takes 172 hours! This means that just to

heat treat this blade takes over a week! The reason for this is

scientific and critical, but yields the most stable, most

wear-resistant, most durable and long-lived structure of this

steel, profuse with fine multi-element carbides and a uniform

and unbelievably robust structure. The result is an incredibly tough, very hard,

very wear-resistant stainless steel. This is a testament to my

determination to make the very best knives, steels, treatments

and kits in the modern world. I know of no one else who has

advanced the treatment to this level; it's unheard of in the

metals and knifemaking field. This is, simply

put, ATS-34 at its very finest advanced condition.

- Blade Design and Geometry: I double-hollow-ground the

edges of this Shrike blade with a 3" contact wheel,

something few, if any, other makers do, simply because it's very

difficult to achieve. What this tight grind geometry produces is

a blade that is extremely thin at the cutting edge, yet

thick and substantial down the central spine, critical for

support of a double-edged knife blade. This is a double-edged

tanto design, so the secondary cutting apex of the tanto can be

used to bear down when cutting in utility chores, and the tanto

point is wide-angled and very strong, for the thin geometry. The blade has no choils to become

trapped or snagged in any clothing, gear, or object being

cut and the cutting edges simply taper to a stop in the grind for smoothness in

motion. The blade has substantial quillons that are

2.5" (6.4 cm) at the widest that serve four purposes: one is

to stop penetration of the blade at its limit, the second is to

protect the fingers from any metal, edges, or projections, the

third is to provide a smooth, rounded, contoured surface for the

fingers for maximum grip security, and the fourth is to engage

in the sheath retention method in the leather (described below). The blade is supported by a

1/4" thick and heavy central neck-ricasso to provide transfer of force from the

hand to the blade edges and point, and the handle tang is full

thickness in the palm for a solid, complete support.

- Blade Finish: The blade is finished in my flat,

dark "Shadow" line of

counterterrorism, rescue, and tactical knife finishes. Answering

the request for completely subdued and non-reflective

surfaces, I developed the Shadow Line with my Ghost

Slate finish. This means darkening in a permanent

fashion the stainless steel of the knife, with matching sheath. Read more about

my Shadow Line and Ghost Slate finish on my

Counterterrorism Knives page

at this bookmark.

- Handle: I milled the tang in a skeletonized

geometry, for ultimate weight reduction. The skeletonized handle

tang is the lightest possible, and all surfaces are rounded,

contoured, and smoothed for a comfortable, extremely lightweight

grip. This type of handle results in a knife that is fully half

of the weight of full tang punch daggers with handles. This

results in a thinner, lower flat profile when sheathed, as well. The

handle of the Shrike is designed with one of my "talon" palm

heel points, used in my popular "Guardian" and "Ari B'Lilah" models. The notable thing is that this

talon is comfortably concealed in the sheath, safe for the knife owner; he won't

encounter the point unless the knife is unsheathed.

- Balance and Feel: The balance

point of the knife is exactly at the quillons,

and the knife feels extremely lightweight, yet strong, molded to the hand when

gripped in the fist. By design, the fingertips engage the inside of the

handle milling for extra secure grip. This knife was conceived for the wearer to

be able to immediately put it in his hand, with the handle

shank between the first two fingers, in closed-fist form,

without an elaborate grip technique, and to use or defend his life with

simple punching and and thrusting motion natural to human

movement. No matter where the enemy is attacking, the blade will

yield an extremely aggressive point and razor-sharp cutting edge

with enough power behind it to drive through heavy clothing,

around gear and equipment with tremendous force. The tanto

design of the blade makes it a sure performer for daily carry

and work as well.

- This is an serious defensive and tactical weapon

for the most critical of counterterrorism and tactical close

quarters combat situations, while being a fully functional

daily carry useful utility tool.

Included:

The Sheath

The Positively Locking Leather Sheath

- Weight: 6.9 oz. (196 grams)

- Materials: 9-10 oz. Leather Shoulder, Nylon

high strength thread, stainless steel Chicago screws, stainless

steel dot snaps

- Description: I've created an advanced leather

sheath for this model, based on client feedback and necessity of

safety and strength for daily carry. My clients may typically wear a leather

sheath for daily carry, so I wanted to create a leather sheath that

was as close to indestructible as leather can be. I started with the

thickness; this is thick shoulder, about 0.2" (5 mm) thick, as heavy as

leather armor, and the heaviest leather straps for rigging, and

twice as thick as the leather on a saddle. I hand-stamped/tooled the

sheath in a bordered randomized design, and dyed it black. The first thing you'll notice

about the sheath is the very high front,

covering the knife blade and handle almost completely, protecting

the wearer from the persuader point. It also shields the knife

handle from view for privacy. On the sheath front are two "D" shaped tab

stitched points; these are the locations of the two D-shaped tab

retention points that engage specific locations on the knife handle.

These tabs have stainless steel (corrosion-proof and very strong)

dot snaps that snap to the inside sheath back. When the knife is in

the sheath, these dot snaps are engaged, making two audible and

tactile "snaps" that assure the wearer that the knife is secured.

When snapped, it's impossible for the knife to be removed, to fall,

to vibrate out, or to even be forced from the sheath. This makes

this design a positively-locking leather sheath that can't be forced, even in

the most violent and active situations. When the wearer wants to

remove the knife, he pushes his fingertips into the handle,

unsnapping and folding the front face of the sheath outward,

unsnapping the tabs, moving them out of engagement points on the knife handle. Because the front of the

sheath folds, it's made of extra-thick leather and it's reinforced

at that critical point with two 304 stainless steel Chicago screws,

which go completely through the sheath front, welts, and sheath back. This

way, no stress is on the stitching at this point. What about the

stitching? The belt loop I secured with double row stitching of

nylon, for great strength and durability. The belt loop

will accommodate a 2.0" wide belt. On the welts, back, and front, I

stitched the sheath with double-row stitches, for extreme strength,

stiffening, and durability. The sheath is rounded, contoured,

smoothed, and sealed with three coats of lacquer for longevity.

- Casual and PSD wear: Clearly, most of my

tactical and combat gear cannot be mistaken for utility wear. Heavy,

solid kydex sheaths can be bulky and weighty to wear in the casual

sense, nor are they meant to be. The Shrike sheath is different.

Because it's hand-tooled leather, more common daily and casual wear

is possible, traditionally on the belt. This makes the knife a good

choice for PSD (Principal Security Detail, or Security Detail) work.

- Simply put: This is the most secure, durable,

and well-constructed leather sheath possible.

Included:

Storage

- Envelope Bag: 1000 denier Cordura® ballistic

black nylon, waterproof polyurethane coated, inside layered in heavy

polyester felt. Stainless steel dot snaps, embroidered patch, removable

embroidered name patch with hook and loop

Please click on thumbnail knife photos of this Shrike!